Forging integrated type oiling strain clamp for aluminum alloy stranded wire

A technology of tension clamp and aluminum alloy, which is applied in the direction of adjusting/maintaining mechanical tension, and can solve the problems of tension clamp freezing, tension clamp corrosion, accidents, etc., to achieve a complete and long metal flow line The effect of service life and continuity guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

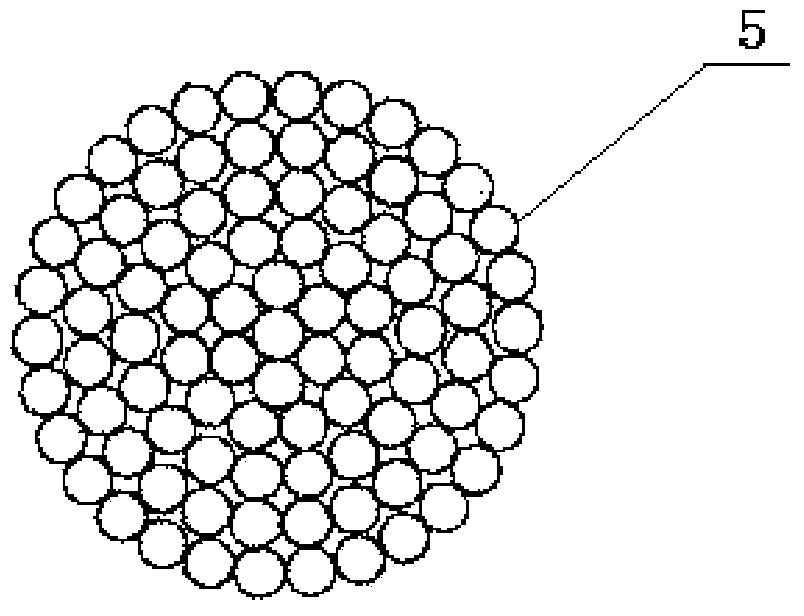

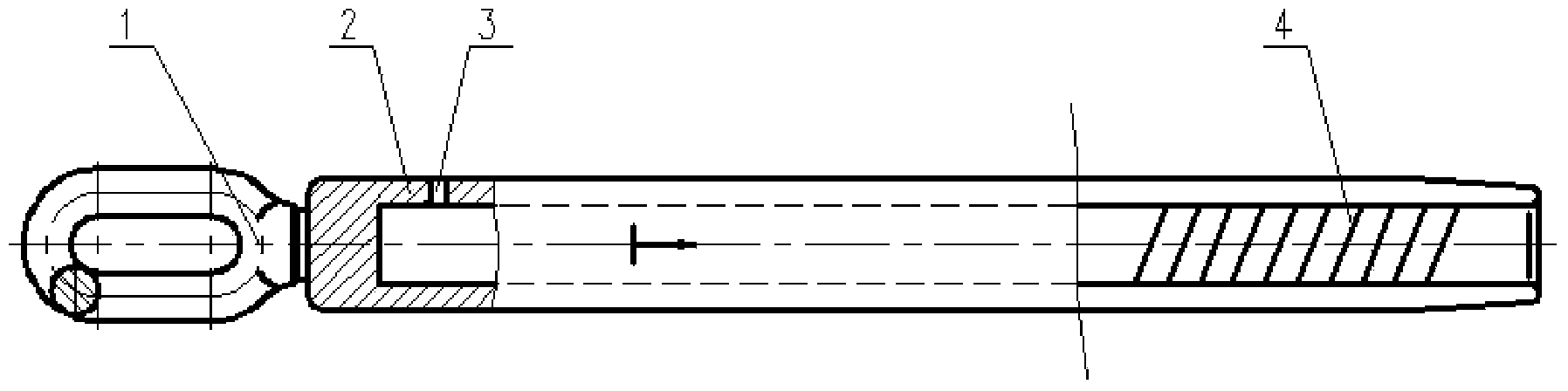

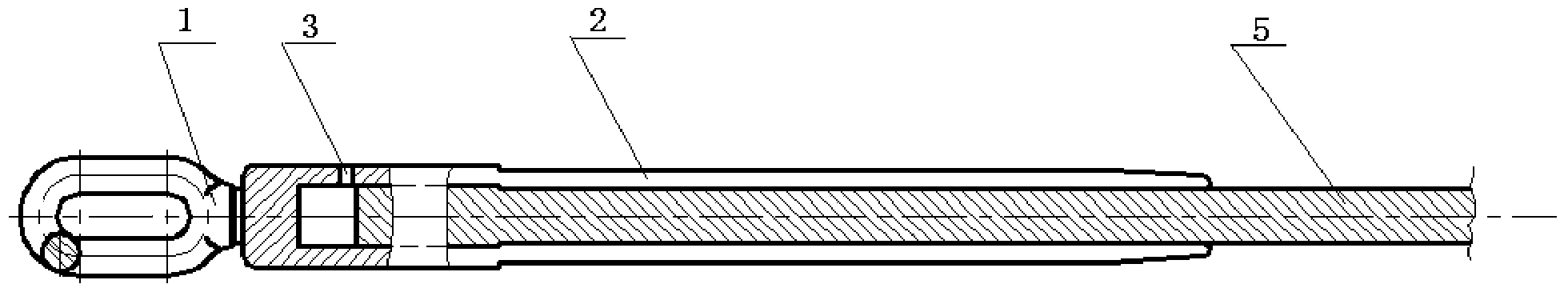

[0046] The strain clamp is made of aluminum alloy forged as a whole. There is an oil injection hole 3 on the side wall of the connecting pipe 2 at the connection between the pull ring 1 and the connecting pipe 2. On the inner wall of the connecting pipe 2 nozzle, there is a single The helical cross-section is tapered fixing piece 4, and its apex angle is 30°, and a puller is provided on the outside of the nozzle of the connecting pipe 2. Put the ring of the diversion plate 6 on the connecting pipe 2 and weld it together, insert the aluminum alloy stranded conductor 5 into the connecting pipe 2, and pass the oil injection hole 3 to between the connecting pipe 2 and the aluminum alloy stranded conductor 5 Fill the gap with electric grease, and then integrate it by hydraulic crimping. The top angle of the fixing part 4 is closely engaged with the aluminum alloy stranded conductor 5, so that the cavity after the tension clamp and the conductor are crimped is fully sealed, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com