A precision casting method for the skeleton of a superalloy hollow complex thin-walled structural part

A technology of thin-walled structural parts and high-temperature alloys, which is applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of complexity, easy generation of looseness, and difficult casting process, so as to improve the qualification rate and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

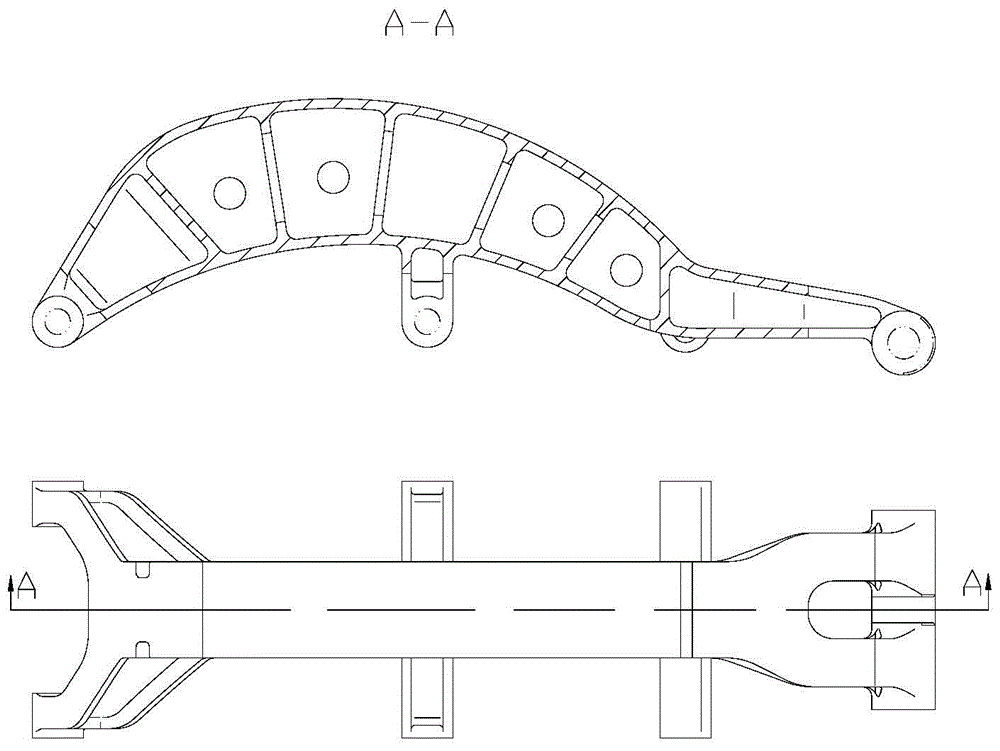

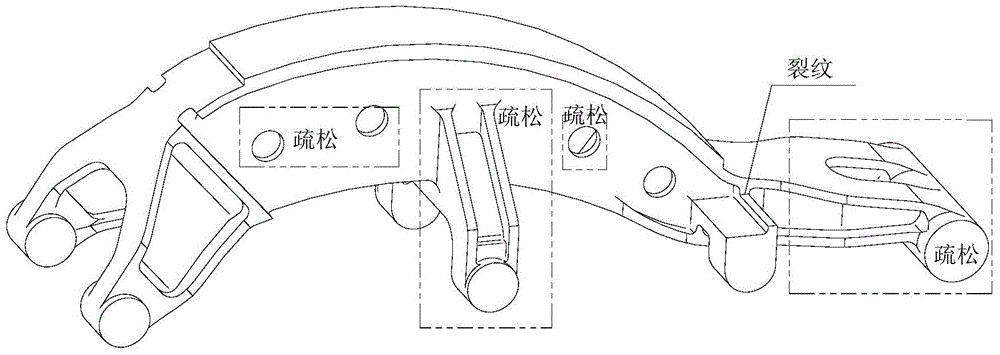

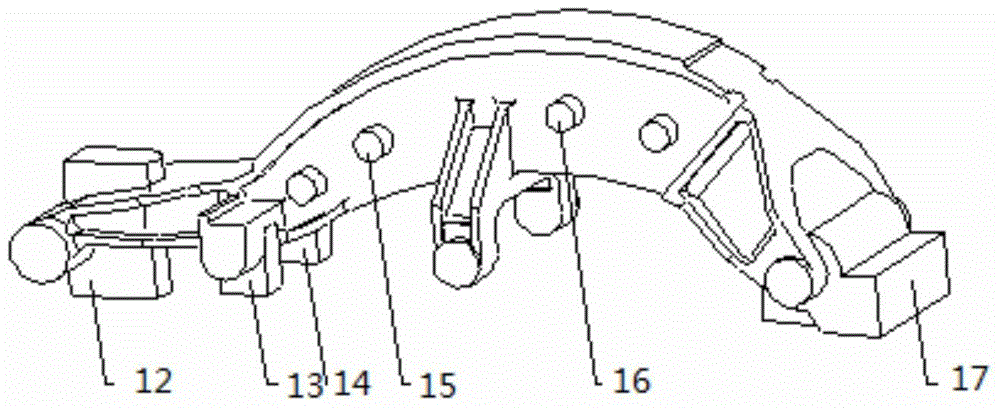

[0026] Castings such as figure 1 It is shown that there are many heat joints, and the casting process is more difficult, such as figure 2 As shown, metallurgical defects such as loose skeleton castings are prone to occur in the square frame area. Since castings are not allowed to be repaired and welded, they will be scrapped if the defect diameter exceeds the standard after pouring; the inner cavity of the casting is a complex hollow structure, and there are 6 cores when pressing the wax mold. Combined to form together, such as image 3 As shown, carry out the research on the investment casting process of skeleton castings, and determine the appropriate gating system combination scheme, such as Figure 4 Shown and pouring process as Figure 5 As shown, high-quality skeleton precision castings have been developed.

[0027] The present invention relates to a precision casting method for the skeleton of a complex thin-walled structure of a superalloy cavity, which is carried ...

Embodiment 2

[0041] Embodiment 2 is basically the same as the method of embodiment 1, parts such as Figure 6 As shown, adjust the size of the gating system according to the size of the part, the difference is:

[0042] (1) Wax mold manufacturing: Wax mold manufacturing is carried out according to the shape of the casting; when the wax mold is pressed, it is formed by combining three cores, and each wax piece needs to prepare a polyethylene glycol (urea core) soluble type Core and 2 ceramic cores; the process parameters of the high-pressure wax press machine mold are: holding time 150s, injection pressure 1.4MPa, wax temperature 68°C;

[0043] (3) Vacuum melting of castings

[0044] Packing process: the preheating temperature of the shell in the high-temperature furnace is 980°C±10°C, and the holding time is 3h;

[0045] Pouring process: The master alloy material used for the skeleton casting is K424 alloy, and the pouring equipment adopts a 50kg vacuum furnace; in order to control defec...

Embodiment 3

[0047] Embodiment 3 is basically the same as the method of embodiment 1, parts such as Figure 7 As shown, adjust the size of the gating system according to the size of the part, the difference is:

[0048] (1) Wax mold manufacturing: Wax mold manufacturing is carried out according to the shape of the casting; when the wax mold is pressed, it is formed by combining three cores, and each wax piece needs to prepare a polyethylene glycol (urea core) soluble type core and 2 ceramic cores;

[0049] The process parameters of the high-pressure wax machine mold: the holding time is 120s, the injection pressure is 1.5MPa, and the wax temperature is 66°C;

[0050] (3) Vacuum melting of castings

[0051] Packing process: the preheating temperature of the shell in the high temperature furnace is 1100℃±10℃, and the holding time is 4h;

[0052] Pouring process: The master alloy material used for the skeleton casting is K424 alloy, and the pouring equipment adopts a 50kg vacuum furnace; i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com