Cold and hot temperature difference assembled and disassembled gear device

A technology of gear device and temperature difference between cold and heat, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as labor and time-consuming, and achieve the effect of saving cost and shortening maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

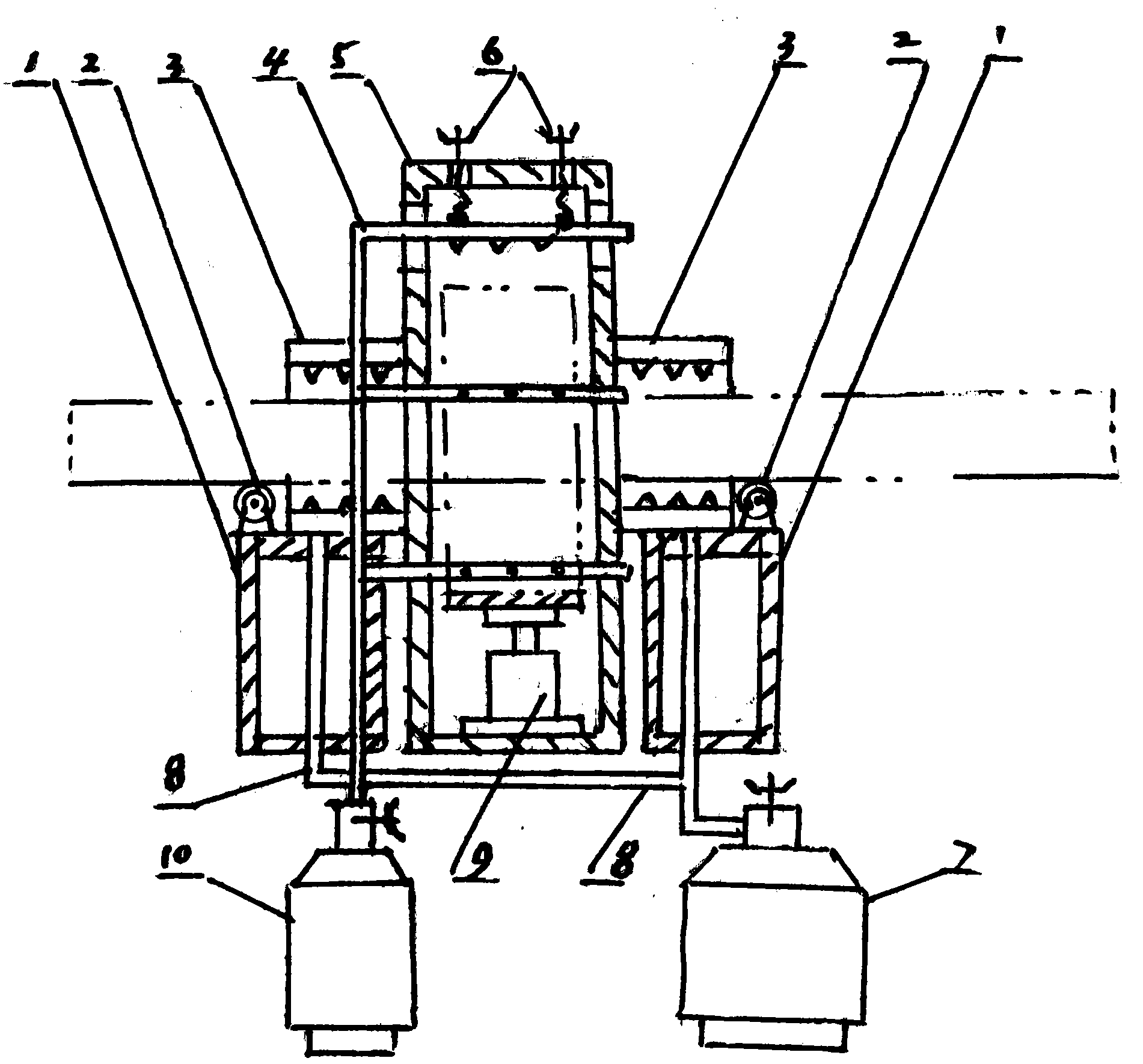

[0009] In the embodiment shown in the figure, the gear cover 5 is divided into two halves and connected by screws, and the center of the two side plates of the gear cover 5 is provided with a shaft passing hole. Gear cover 5 bottoms are provided with jack 9, are provided with many rows of nuts on gear cover 5 outer circles, and every row has two nuts, and adjusting screw rod 6 is screwed on nut and is fixed. A plurality of heating tubes 4 are uniformly arranged in the gear cover 5 and are flexibly connected with the adjusting screw rod 6 to adjust the distance between the heating tubes 4 and the gears. The heating pipe 4 is provided with a nozzle, and the heating pipe 4 is connected to the liquefied gas tank 10 with a hose 8 . The cooling bushing 3 is provided with a nozzle and an air inlet pipe for the hollow torus. Two cooling bushings 3 and two supporting rollers 2 are installed on two iron stools 1 respectively, and the supporting rollers 2 can make the shaft move easily,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com