Extracorporeal circulation cooling device for auxiliary electrolyzer

A technology of extracorporeal circulation and cooling device, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of electrolyte corrosion to electric pump, waste of financial resources, etc., and achieve the effect of safe and reliable operation steps, energy saving, and simple operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

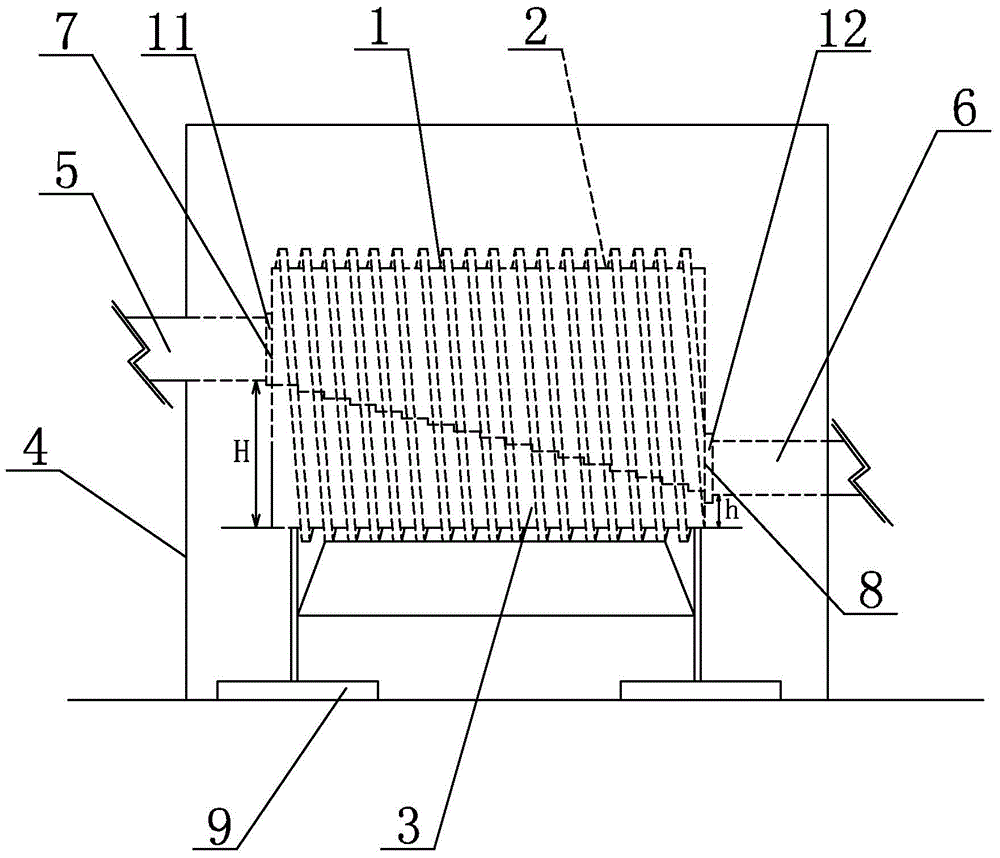

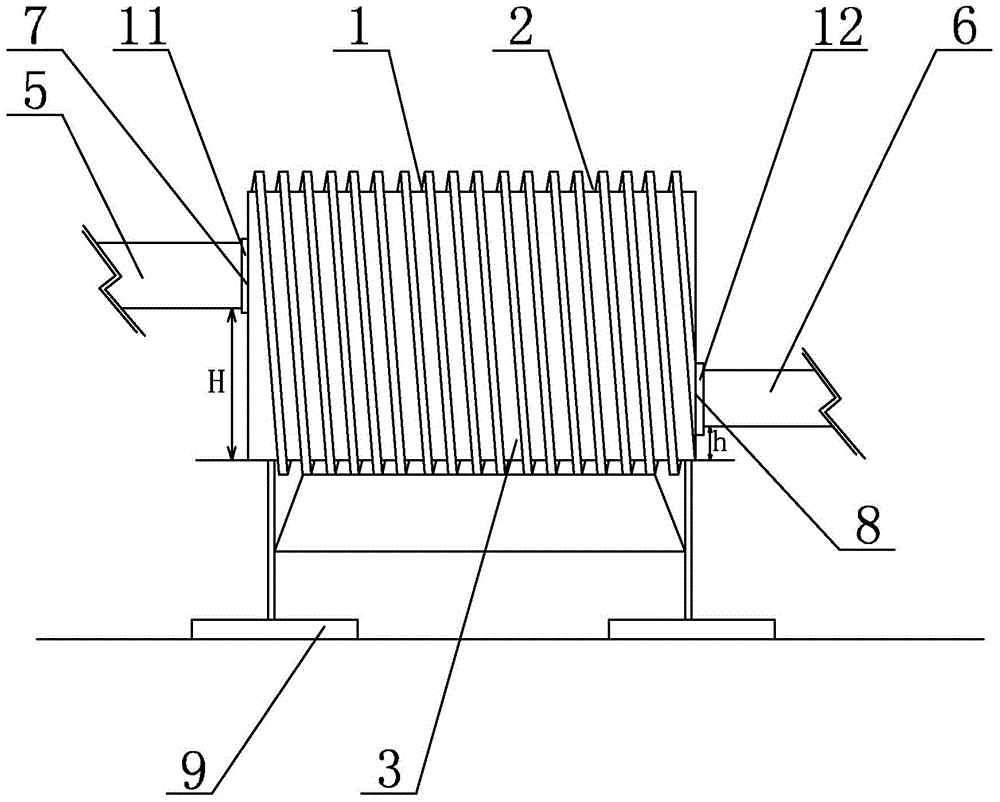

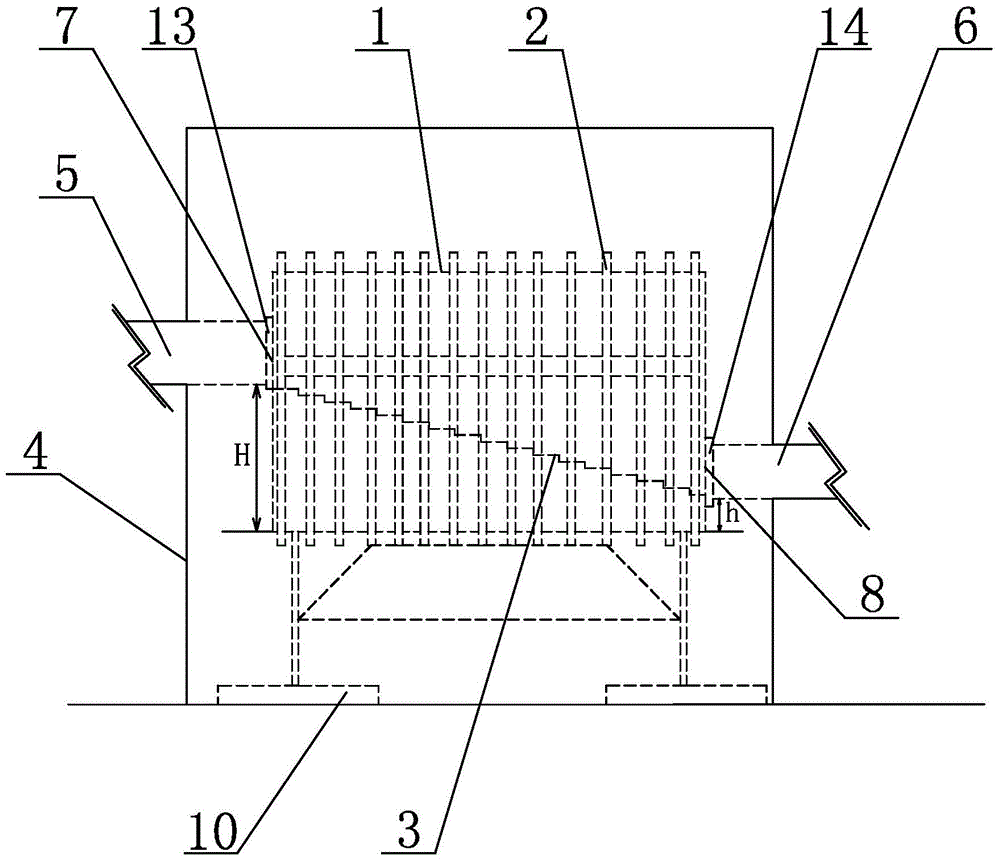

[0013] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, the auxiliary electrolytic cell extracorporeal circulation cooling device described in this embodiment includes a cooling main casing 1, a cooling pipe body 2, a stepped diverter plate 3, an outer cover body 4, a first pipeline 5 and a second Pipeline 6, the cooling main casing 1 is a sealed hollow body arranged horizontally, the cooling pipe body 2 is wound outside the cooling main casing 1 and arranged in a gap with the cooling main casing 1, the cooling main casing 1 An electrolyte inlet port 7 is processed on one side of the body, the first pipeline 5 communicates with the electrolyte inlet port 7, an electrolyte outlet port 8 is processed on the other side of the cooling main casing 1, and the second pipe The road 6 communicates with the electrolyte outlet port 8, the vertical distance from the electrolyte inlet port 7 to the bottom of the cooling ma...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 To describe this embodiment, the cooling main casing 1 in this embodiment is a cylinder or a cuboid. According to the specific working environment of the present invention, the cooling main housing 1 of suitable shape is selected to cool down the electrolyte in the electrolytic cell, and the volume of the cooling main housing 1 is 12000 cm 3 , when the cooling main casing 1 is a cylinder, the radius of the circular surface in the cylinder is 8.7cm, and the length is 50cm; when the cooling main casing 1 is a cuboid, the cuboid has a length of 50cm, a width of 30cm and The height is 8cm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, in this embodiment, between the vertical distance H between the electrolyte inlet port 7 and the bottom of the cooling main casing 1 and the vertical distance h between the electrolyte outlet port 8 and the bottom of the cooling main casing 1 The distance difference is 8cm to 12cm. The optimal height difference between H and h is 10 cm, and this distance makes the cooling time and flow effect of the electrolyte in the cooling main casing 1 optimum. The other components and connections are the same as those in Embodiments 1 and 2.

[0017] Specific implementation mode four: combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment. In this embodiment, the cooling pipe body 2 is a spiral pipe body. On the cooling main casing 1. Other components and connections are the same as those in the third embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com