Steel wire bar flower needle device, assembly tooling and assembly method of the device

A technology for assembling tooling and wire combs, which is applied in knitting, metal processing, and tool manufacturing. It can solve problems such as the inability to guarantee needle components, affect distance accuracy, and high labor intensity, and achieve convenient installation, fast pattern change, and production. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

[0046] Option One:

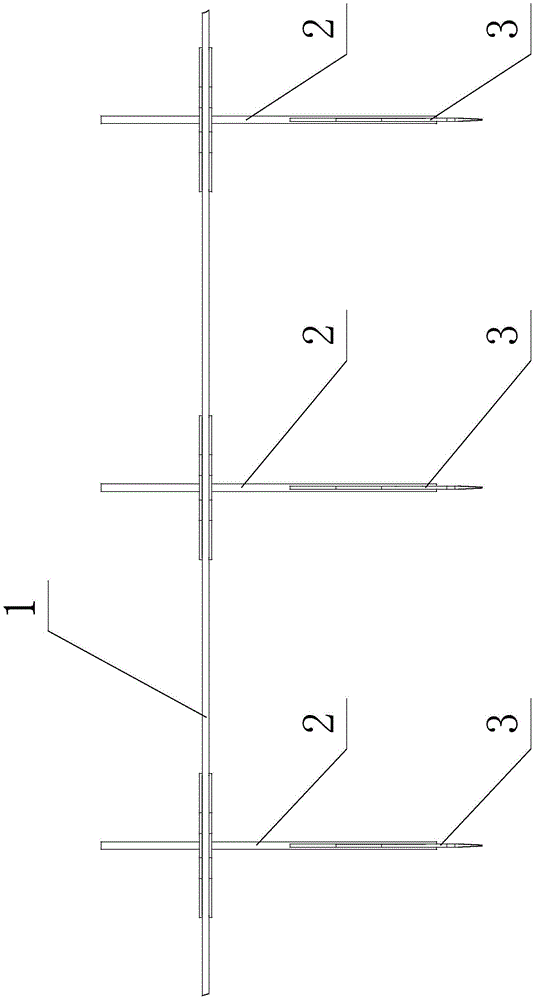

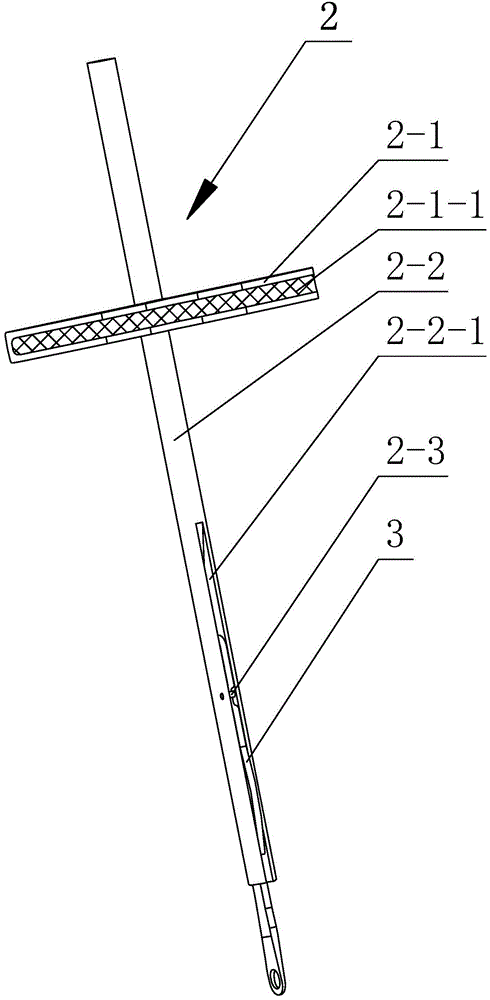

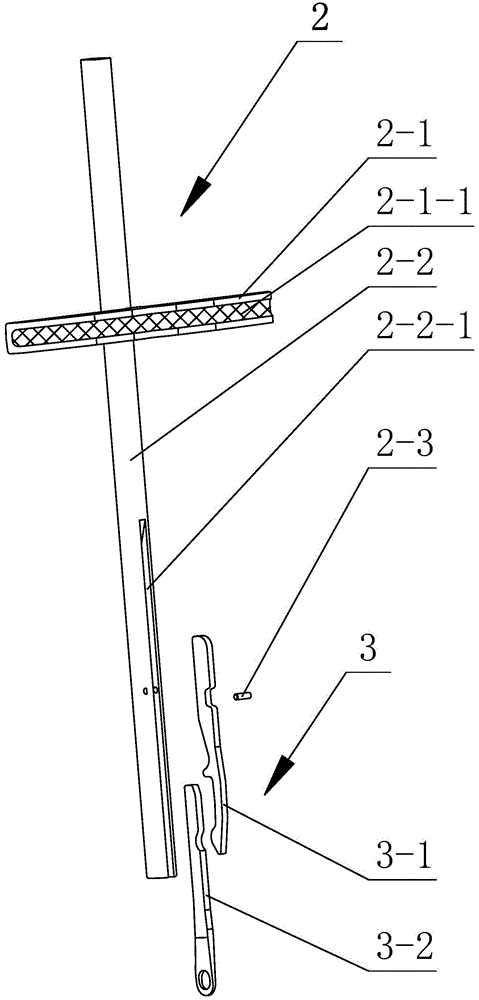

[0047] A steel wire comb flower needle device, such as Figure 1-Figure 7 As shown, the device comprises steel wire 1, more than one group of flower needle mounting frames 2 that are fixedly installed on the steel wire 1, and flower needle assemblies 3 that are respectively installed on each group of flower needle mounting frames 2, and is characterized in that: each group of flower needles The needle mounting frame 2 includes a horizontal needle bar 2-1 fixedly connected in parallel with the steel wire 1 and a vertical needle bar 2-2 vertically fixedly connected with the horizontal needle bar 2-1. The flower needle assembly 3 is installed on the vertical needle. on the rod 2-2; the transverse needle rod 2-1 is provided with a groove 2-1-1 arranged along the length extending direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com