A Coal Pressure Relief Method for Steeply Inclined Extra-thick Coal Seam

An ultra-thick coal seam and steeply inclined technology, which is applied in the field of coal pressure relief in steeply inclined ultra-thick coal seams, can solve the problem of affecting the top-coal caving performance and safe and efficient mining, and cannot better achieve coal seam water retention, fracturing, and wetting Problems such as difficult to improve, to achieve the effect of ensuring effective mining, ensuring mining safety, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

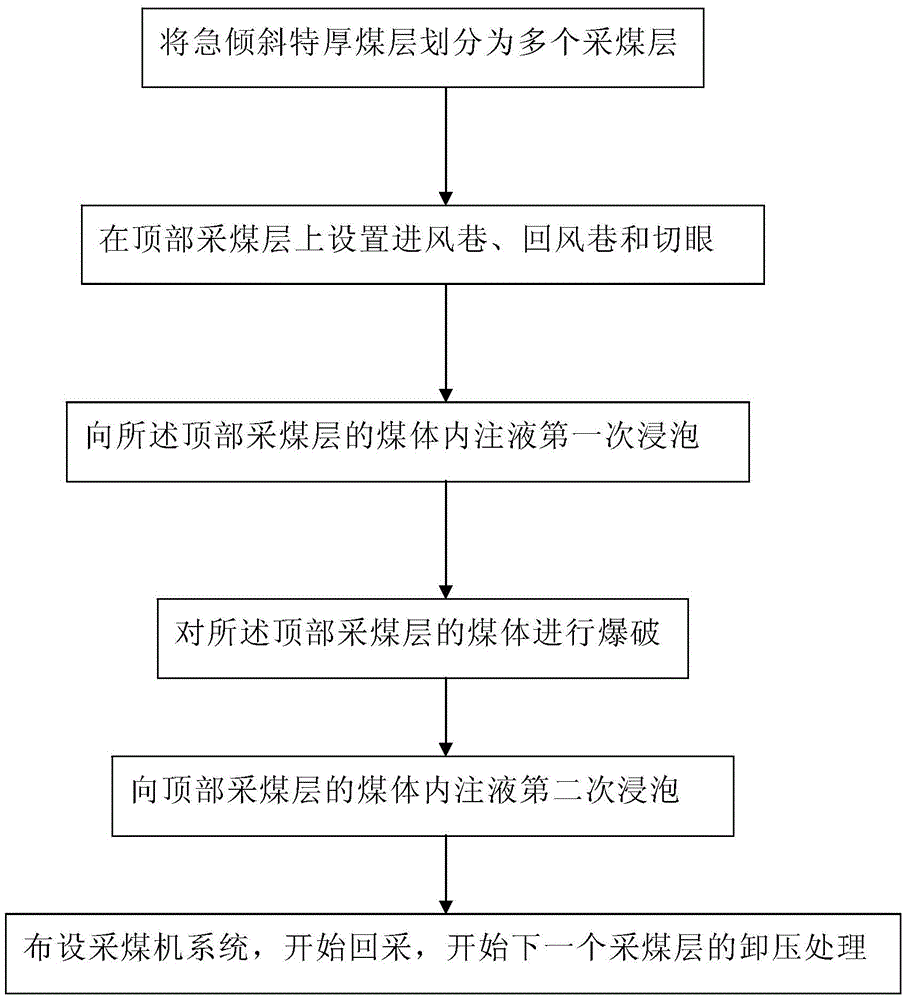

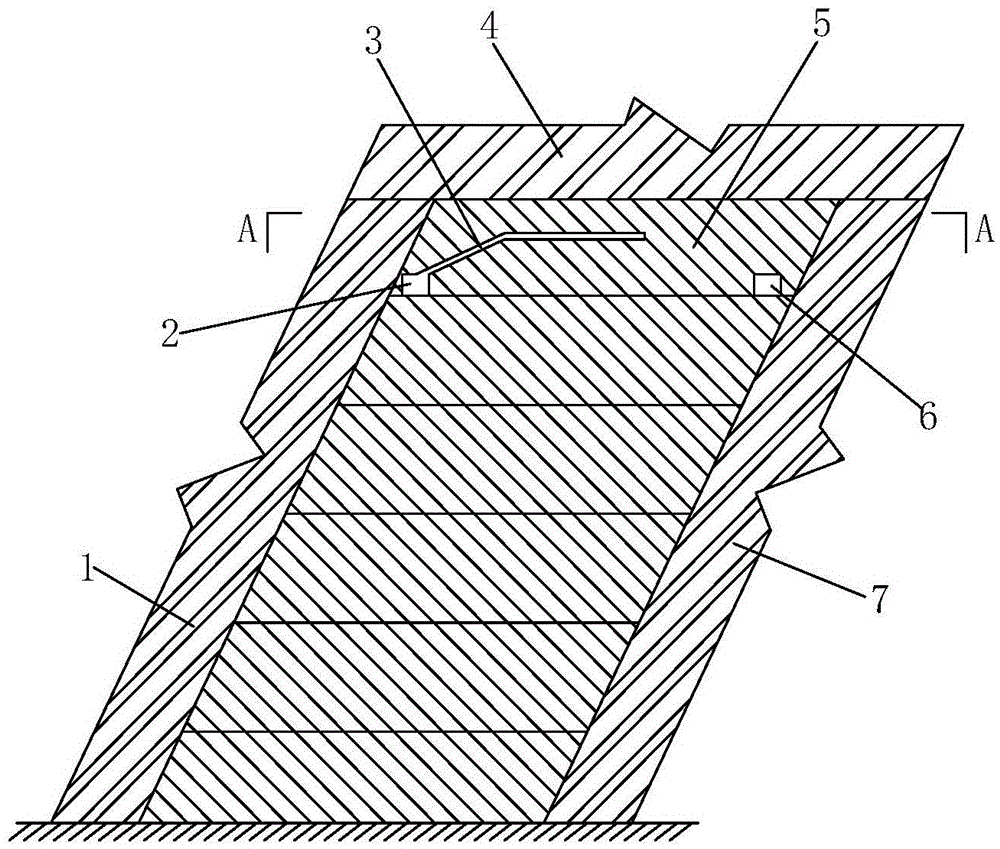

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 A coal pressure relief method for a steeply inclined extra-thick coal seam is characterized in that it comprises the following steps:

[0028] Step 1. Divide the steeply inclined extra-thick coal seam into multiple coal mining seams in the vertical direction, and the thickness of each coal mining seam is about 20m to 30m.

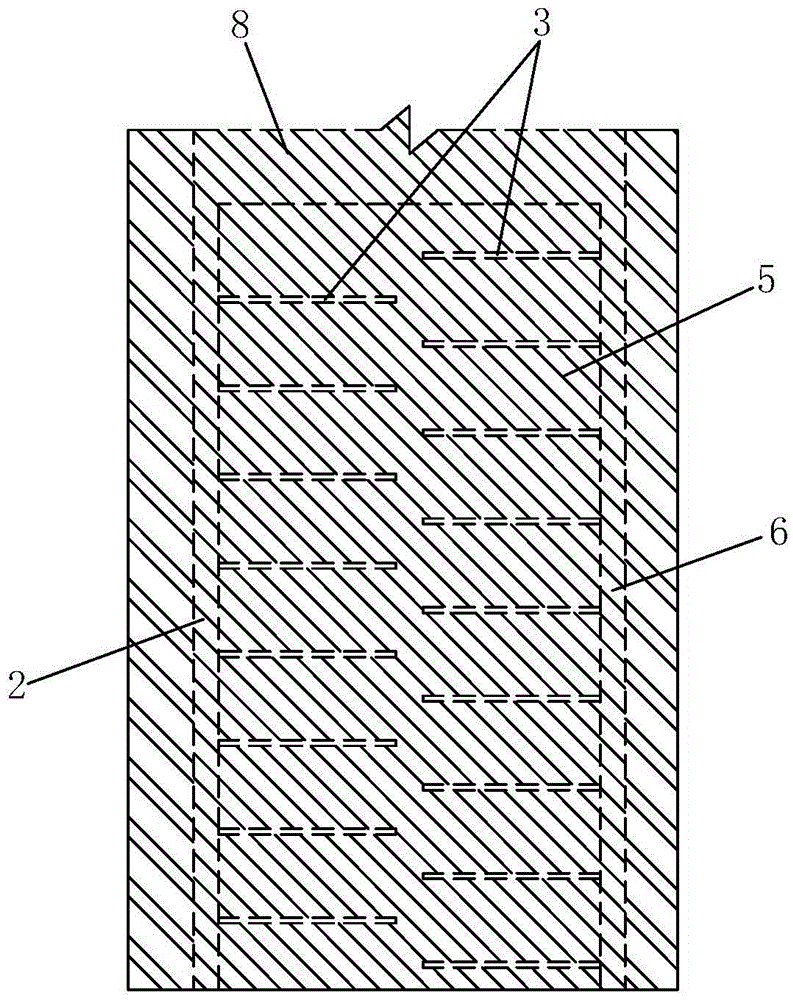

[0029] Step 2, first set the air inlet lane 2 and the air return lane 6 on the top coal mining seam 5, and the cutout 8 for connecting the air inlet lane 2 and the air return lane 6;

[0030] Step 3: Make a first liquid injection hole 3 in the coal body of the top coal mining seam 5 in the air inlet lane 2 and the air return lane 6, and then inject alkaline medium into the first liquid injection hole 3 solution and soak the coal body of the top coal mining seam 5 for the first time;

[0031] Step 4: Open a blast hole to the coal body of the top coal seam 5 in the air inlet lane 2 and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com