High-compressibility and high-resilience sealing assembly

A sealing component, high-rebound technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of seal leakage, loss of seal pressure, lack of seal pressure, etc., to ensure safe production, good rigidity, guarantee The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

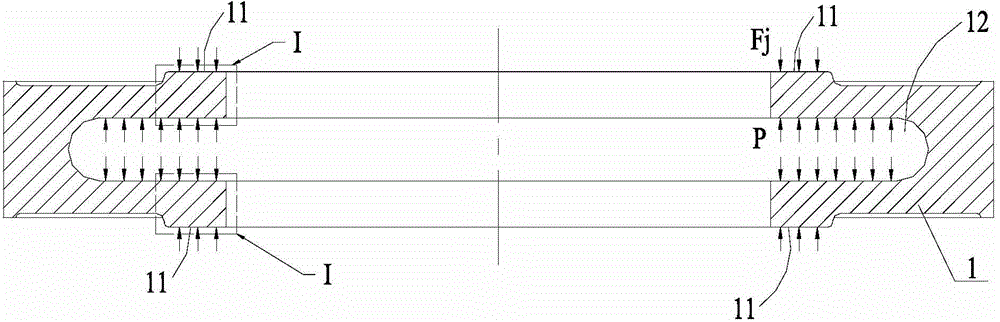

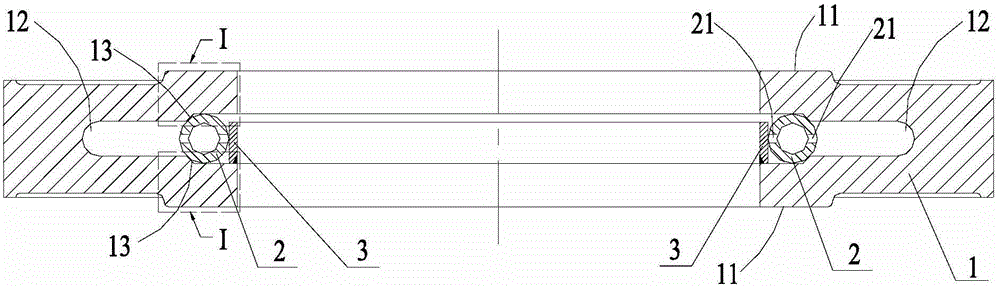

[0050] see Figures 1 to 5 A high compression and high resilience sealing assembly 100 is shown, the sealing assembly 100 includes a metal ring 1, the two axial end surfaces of the metal ring 1 are provided with a sealing structure 11 for sealing connection, and the sealing structure 11 is arranged on The radial direction of the metal ring 1 is used to bear the sealing stress or the side where the sealing stress is relatively large, and it is arranged on the inner side of the metal ring 1 , that is, the sealing structure 11 is arranged on two axial end surfaces of the radial inner side of the metal ring 1 .

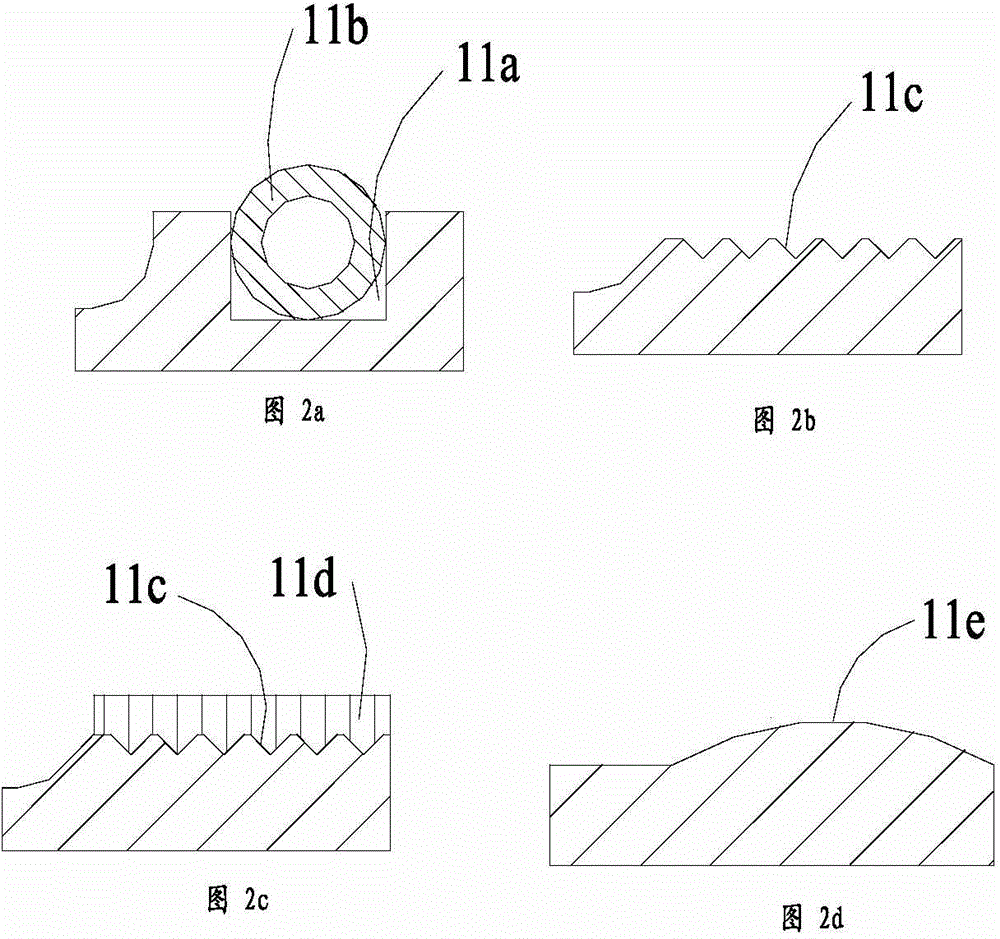

[0051] The sealing structure 11 can be as figure 2 The structural form of a, that is, an annular groove 11a is provided on the axial end surface of the metal ring 1, and an annular sealing ring 11b is arranged in the annular groove 11a, and the annular sealing ring 11b can play a role of metal wire sealing; is like figure 2 In the structural form of b, the axial ...

Embodiment 2

[0067] Such as Figures 9 to 11 As shown, the structure of the sealing assembly 100 in this embodiment is different from that in Embodiment 1 only in the arrangement of the annular groove and the arrangement position of the sealing structure. In this embodiment, an annular groove 16 is formed on the outer peripheral portion of the metal ring 1 , the opening of the annular groove 16 faces outward, and the sealing structure 17 is provided on two axial ends of the radially outer end of the metal ring 1 . The outer side of the annular groove 16 has an open end, and the bottom of the groove is a closed end. An elastic support is provided at the open end of the annular groove 16 .

[0068] This elastic support member can be elastic ring 6, as Figure 10 As shown, it is fixed in the annular groove 16 by the retaining ring 7. The arrangement of the elastic ring 6 and the retaining ring 7 is similar to the arrangement of the elastic ring 2 and the retaining ring 3 in Embodiment 1...

Embodiment 3

[0074] see Figure 13 As shown, the sealing assembly 100 is a collection of the sealing assemblies in Embodiment 1 and Embodiment 2, wherein the inner peripheral portion of the metal ring 1 is provided with an annular groove 12 with an opening facing inward, and the outer peripheral portion is provided with an annular groove 12 with an opening facing outward. Groove 16; on both sides of the metal ring 1, sealing structures are respectively provided at the radially inner and radially outer positions; elastic supports are respectively arranged in the annular groove 12 and the annular groove 16. This can have the effect of double sealing inside and outside.

[0075] The above sealing assembly 100 can also be set as Figure 14 In the structural form shown, the seal between the inner end and the outer end has good elasticity.

[0076] Such as Figure 15 As shown, the sealing assembly 100 is used for the sealed connection between the component 500 and the component 400. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com