Detection method for rectangular pin component visual positioning

A pin component and visual positioning technology, which is applied in the detection field of visual positioning of rectangular pin components, can solve the problems of pin breakage and low positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

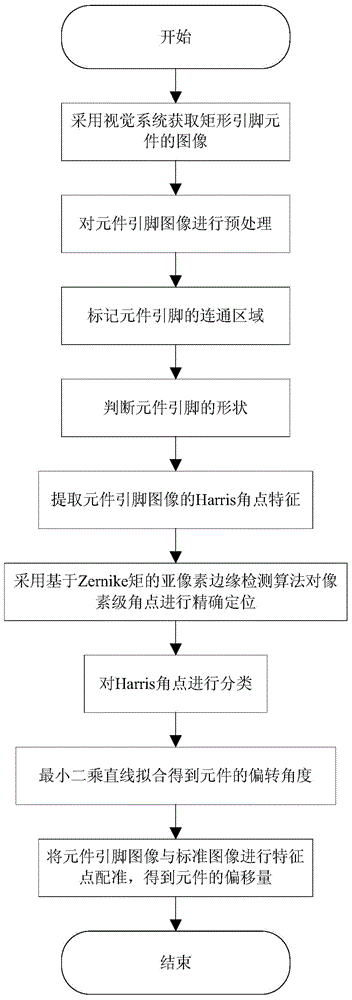

[0036] Specific Embodiment 1: A detection method for visual positioning of rectangular pin components described in this embodiment is implemented in the following steps:

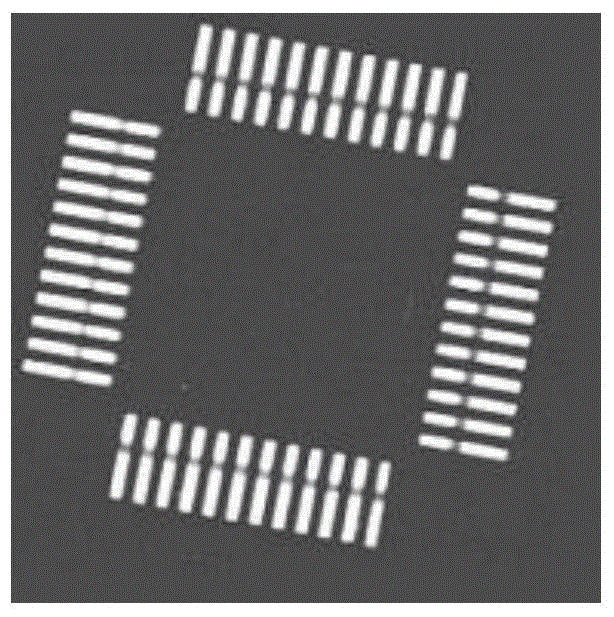

[0037] Step 1: Use the placement machine vision system to obtain the image of the rectangular lead component.

[0038] Step 2: Preprocess the image obtained in Step 1, filter out the noise in the image, repair pin defects, and use the maximum inter-class variance method to perform threshold segmentation to obtain a binarized image.

[0039] Step 3: mark the connected region on the component pin image obtained in step 2.

[0040] The steps to mark the connected regions are:

[0041] Initialization: Randomly select a bright spot B in a connected area in the original image 0 .

[0042] Loop: use square structure element S to B 0 Perform expansion operation, the result after expansion intersects with the original image to get B 1 , repeat the expansion operation and intersection operation until B i+1 ==B ...

specific Embodiment approach 2

[0059] This embodiment is a further supplement to the specific embodiment one, and the Harris corner point extraction method described in step five is specifically implemented according to the following steps:

[0060] (1) Calculate the gradient I of the image I(x,y) in the x and y directions x , I y .

[0061] I x = ∂ I ∂ x = I ⊗ f x I y = ∂ I ∂ y = I...

specific Embodiment approach 3

[0074] Specific embodiment three: this embodiment is a further supplement to specific embodiment one, and the sub-pixel edge detection method based on Zernike moments described in step 6 is specifically implemented according to the following steps:

[0075] (1) According to the ideal model of sub-pixel edge detection, use the template of 7×7 to calculate the 5 rotated Zernike moments Z of each pixel-level corner point 00 ,Z 11 ,Z 20 ,Z 31 ,Z 40 .

[0076] (2) Calculate the 5 Zernike moments Z' after rotation 00 ,Z' 11 ,Z' 20 ,Z' 31 ,Z' 40 .

[0077] (3) Calculate the relationship between the edge parameters of the edge model and the rotated Zernike moments.

[0078] Z 00 ′ = ∫ - 1 l ∫ - 1 - x 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com