Semiconductor test fixture and fabricating method thereof

A technology for testing jigs and semiconductors, which is applied in the direction of single semiconductor device testing, measuring electricity, measuring devices, etc., can solve the problems of weak mechanical structure, low manufacturing accuracy, low testing accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As mentioned in the background art, the performance of the existing thimbles or golden fingers still needs to be improved.

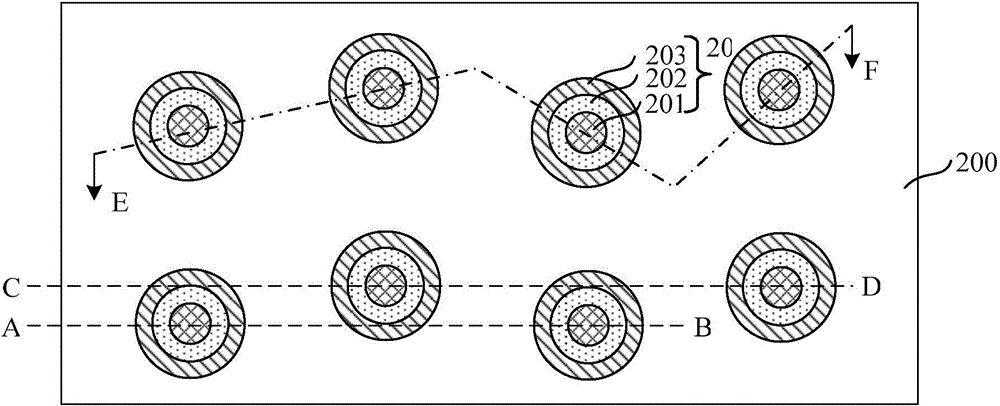

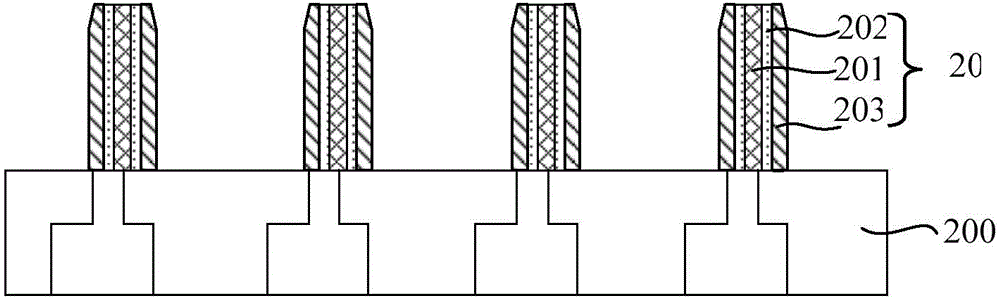

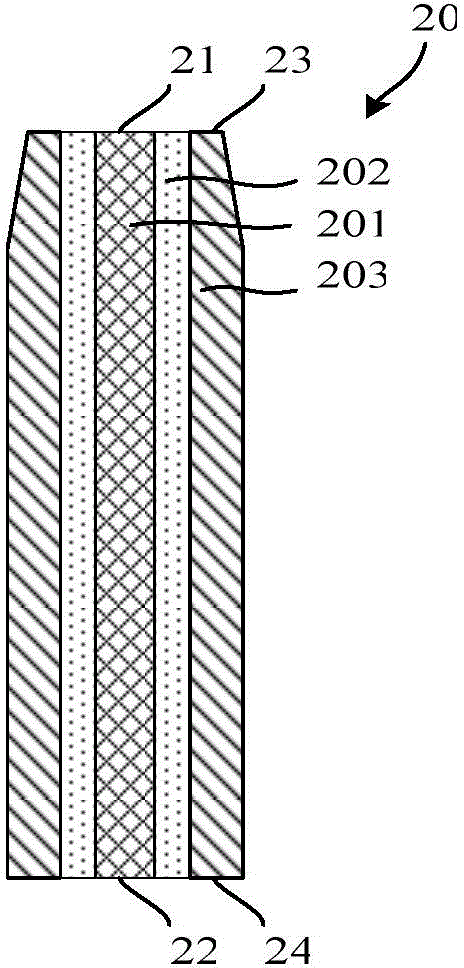

[0028] For this reason, the present invention provides a kind of semiconductor test jig, comprises base; Be positioned at at least one row of test pins on the base, the adjacent test pins in each row are mutually misplaced and arranged, and each test pin comprises: the first test The first test pin includes a first body, a first test end at one end of the first body, and a first connection end at the other end of the first body; the insulation covering the surface of the first body of the first test pin layer; a second test needle located on the surface of the insulating layer surrounding the first test needle, the second test needle is coaxial with the first test needle, the second test needle includes a second body, and a second test terminal located at one end of the second body and a second connection end located at the other end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com