Plug-type button switch

A plug-in and push-button technology, which is applied in the field of plug-in push-button switches, can solve the problems of plug-in inductive switches that cannot meet the needs of use, small electrical load bearing capacity, and large wear of contact parts, so as to improve the operating characteristics and improve The effect of withstanding electrical load and improving electrical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

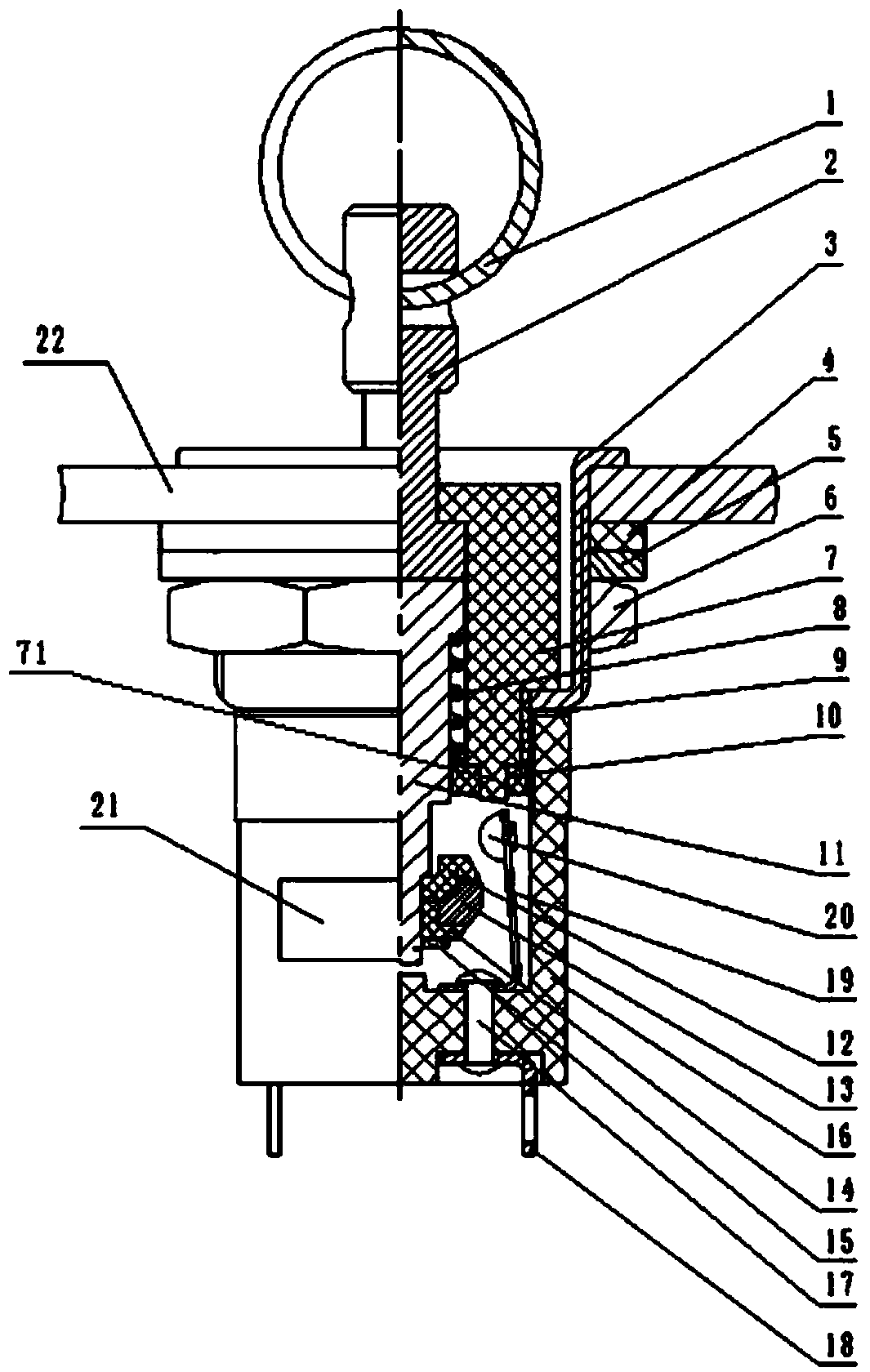

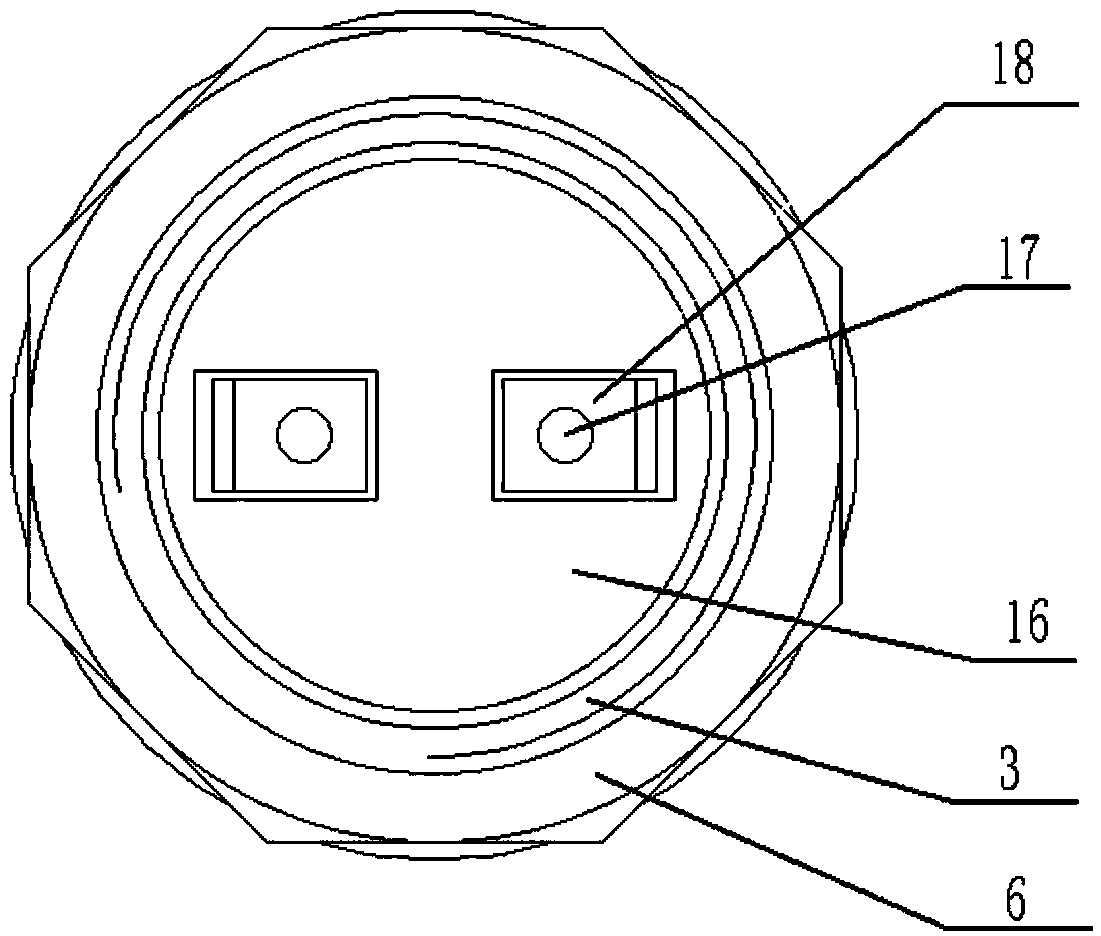

[0021] Such as figure 1 with figure 2 A plug-type button switch shown includes a handle 2, a housing 3, a washer 5, a nut 6, a base A7, a compression spring 8, a fixing plate 10, a push rod 11, a collar 15 and a mounting plate 22; The upper part of the base A7 is installed in the housing 3, and the lower part is fixedly connected with the base assembly through external threads; the housing 3 is fixedly installed on the mounting plate 22 through the washer 5 and the nut 6, and the top end of the push rod 11 is installed on the base assembly. In the seat A7, a compression spring 8 is arranged below the top step surface of the push rod 11, and the lower end of the compression spring 8 is installed on the upper side of the fixing plate 10, and the fixing plate 10 is fixed on the lower end surface of the base A7; The movable contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com