Method of producing a metal reinforcement for a turbine engine blade

A technology of metal reinforcements, reinforcements, applied in the direction of supporting elements of blades, components of pumping devices for elastic fluids, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

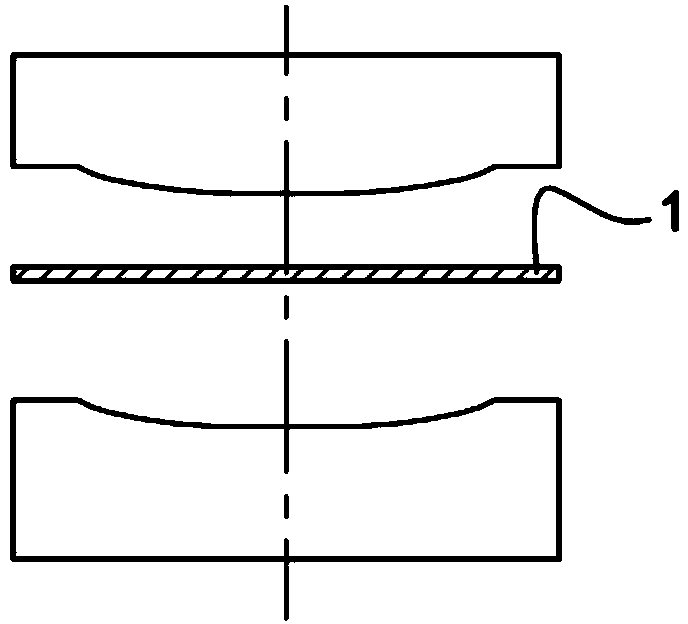

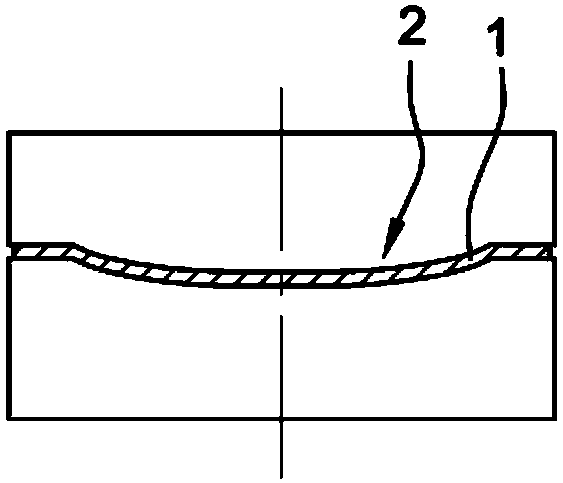

[0051] figure 1 The steps of hot pressing the metal sheets 1 are shown so as to bring their shape close to the final shape of the reinforcement to be manufactured. At the end of this forming operation, each metal sheet 1 has a concave area 2 defining a recess. The sheet 1 is made of a titanium-based alloy such as TA6V. This shaping step is carried out at a temperature of about 940°C.

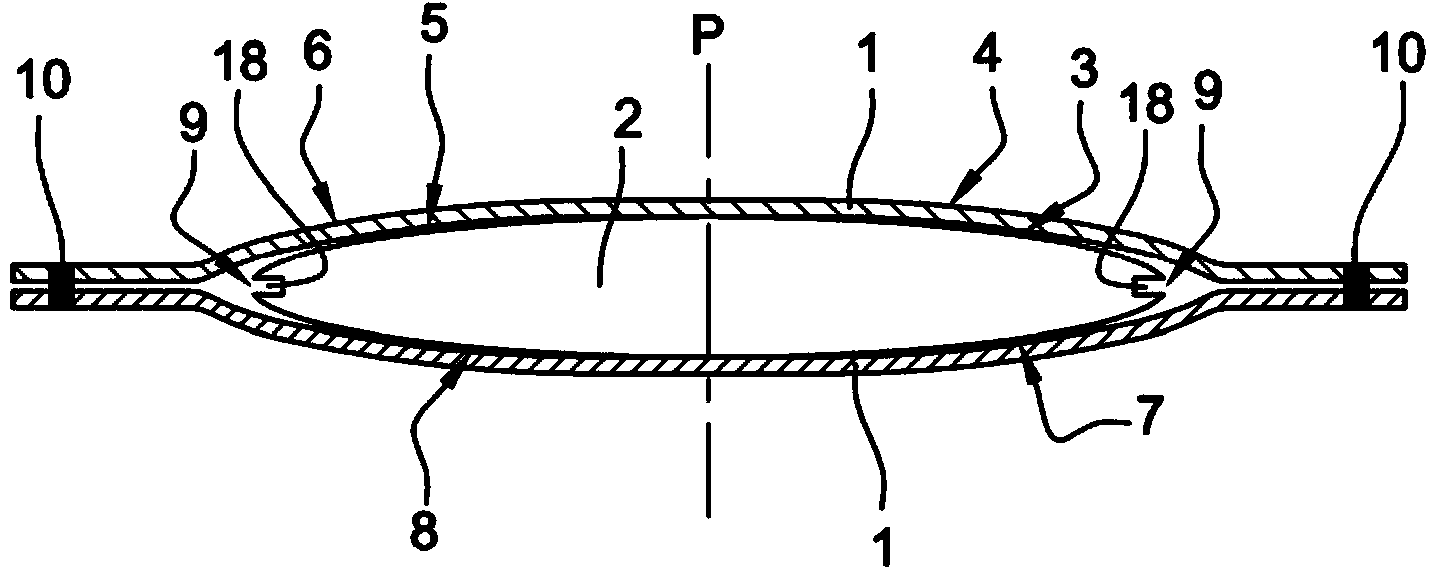

[0052] Such as image 3 As shown in , two identical metal sheets 1 are then placed face to face on either side of the core 2 , each concave side of the sheet 1 receiving a respective part of the core 2 .

[0053] The core 2 has a plane of symmetry P perpendicular to the sheet, comprising a first face that replicates for one half 3 the shape of the inner side of the pressure side of the first stiffener 4 to be produced, and for the other half The portion 5 replicates the inner shape of the suction side of the second stiffener 6 to be manufactured. The core 2 also comprises a second face oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com