Lifting LED grow light device

A technology of LED plant lights and plant lights, which is applied in the field of light devices, can solve problems such as uneven illumination, insufficient illumination intensity, and low light intensity, and achieve the effects of saving energy, reducing power consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

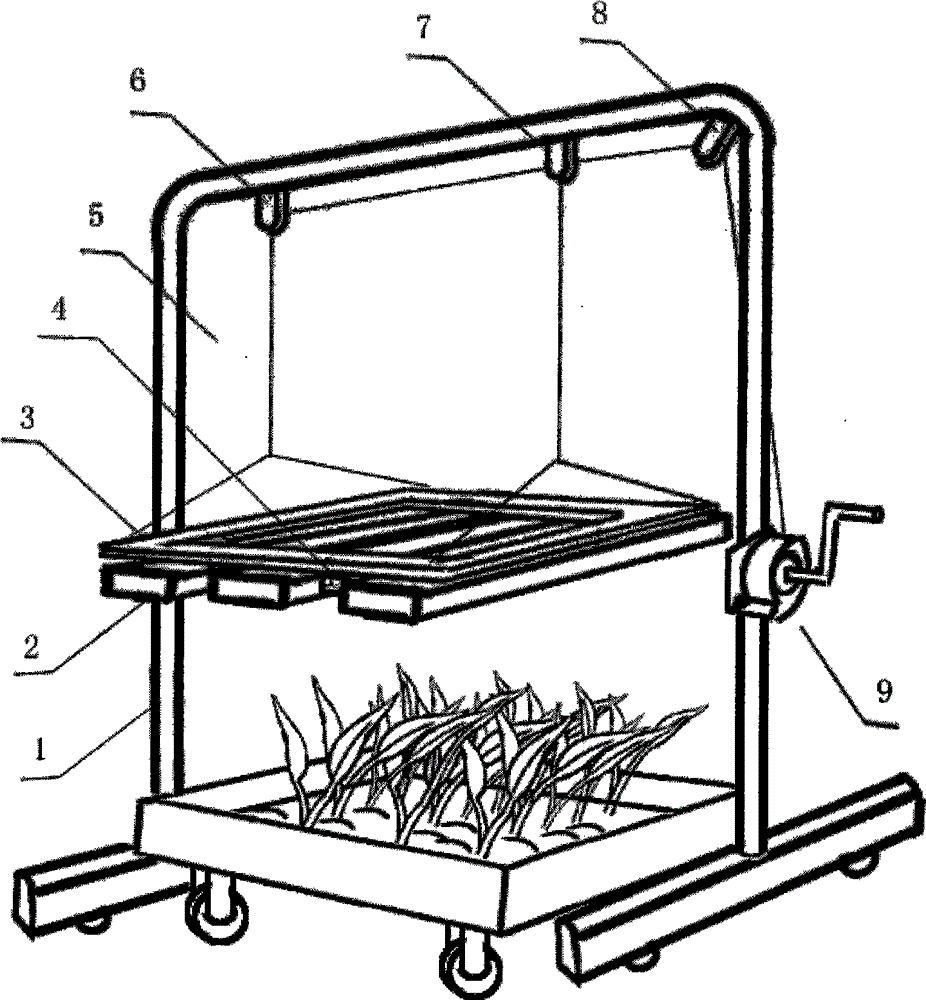

[0013] Depend on figure 1 As shown, an LED plant light device that can rise with the height of the plant consists of an LED plant light bracket (1), an LED plant light group (2), a support platform (3), a laser range finder (4), a wire rope (5), load-bearing pulley (6), load-bearing pulley (7), load-bearing pulley (8), locking capstan (9) form.

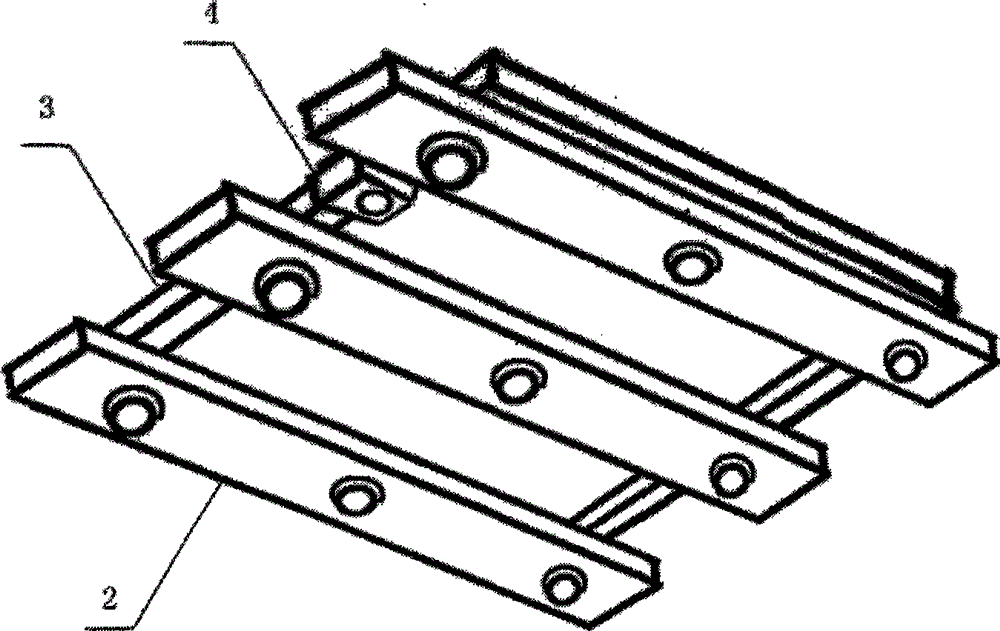

[0014] Such as figure 2 As shown, the LED plant lamp group (2) and the laser range finder (4) are fixed under the bracket platform (3), and the LED plant lamp group (2) and the laser range finder (4) are on the same plane.

[0015] Such as figure 1 As shown, the four corners of the bracket platform (3) are fixed with steel wire ropes (5) and passed through three load-bearing pulleys (6), load-bearing pulleys (7), and load-bearing pulleys (8) of the same specification above the LED plant lamp bracket (1), and The locking winch (9) is connected, and the height of the bracket platform (3) can be raised by turning the locking winch (9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com