Sweet potato peeling and cleaning mechanism

A cleaning mechanism and technology for sweet potatoes, which are applied in the fields of vegetable or fruit peeling, food processing, food science, etc., can solve the problems of unclean cleaning and scraping, slow cleaning speed, etc., and achieve rapid cleaning and peeling, fast cleaning speed, peeling clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

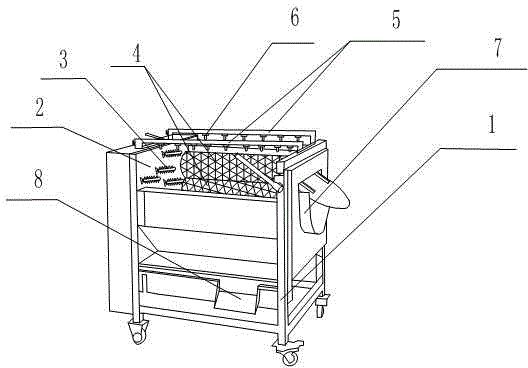

[0016] Such as figure 1 As shown, the present invention includes a frame 1, a cleaning cavity 2 installed on the frame 1, and a plurality of rollers 4 installed in the cleaning cavity 2. A large number of brushes are uniformly arranged on the outer surface of each roller 4, so A plurality of peeling brushes 3 are vertically installed on the inner wall of the cleaning chamber 2, a discharge port 7 is provided on the side wall of the cleaning chamber 2, a slag discharge port 8 is provided at the bottom of the cleaning chamber 2, and a plurality of peeling brushes are provided at the top of the cleaning chamber 2. Parallel water pipes 5, each water pipe 5 is provided with a plurality of spray heads 6, the spray heads 6 are all facing into the cleaning chamber 2, both ends of each water pipe 5 are fixed on the top of the frame 1, and the top of the cleaning chamber 2 is open; A motor is also installed on the frame 1, and the motor is connected to a plurality of rollers 4.

[0017] ...

Embodiment 2

[0019] The preferred specific structure of this embodiment on the basis of Embodiment 1 is as follows: a plurality of scraping sheets are arranged on the surface of the peeling brush 3. Multiple scraping flakes work at the same time, which can scrape more sweet potato peels in the same time, thereby speeding up the scraping speed and improving efficiency.

[0020] The discharge port 7 is adjacent to one end of the drum 4, and a cover that is opened and closed by a rotating rod is provided on the discharge port 7.

[0021] One end of the peeling brush 3 is movably connected to the inner wall of the cleaning chamber 2 and can swing around the connecting end.

[0022] The bottom of the frame 1 is also provided with rollers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com