Wet desulfurization pulping system

A technology of wet desulfurization and pulping, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of reducing floor space and shortening transportation paths, so as to save floor space and reduce transportation links , Reduce equipment investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

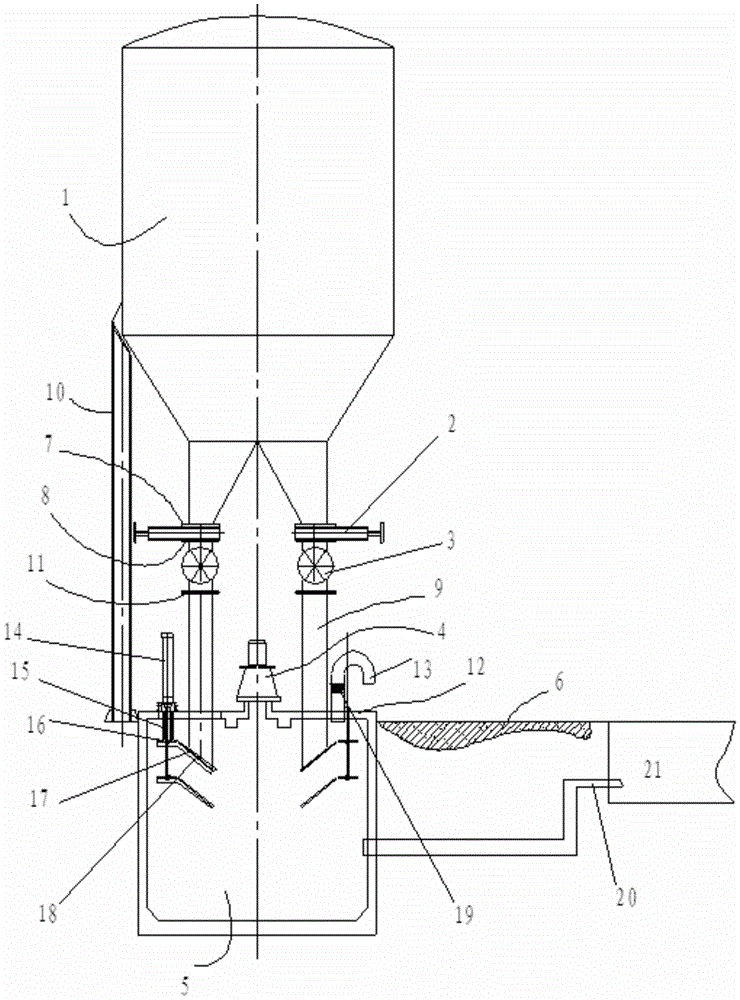

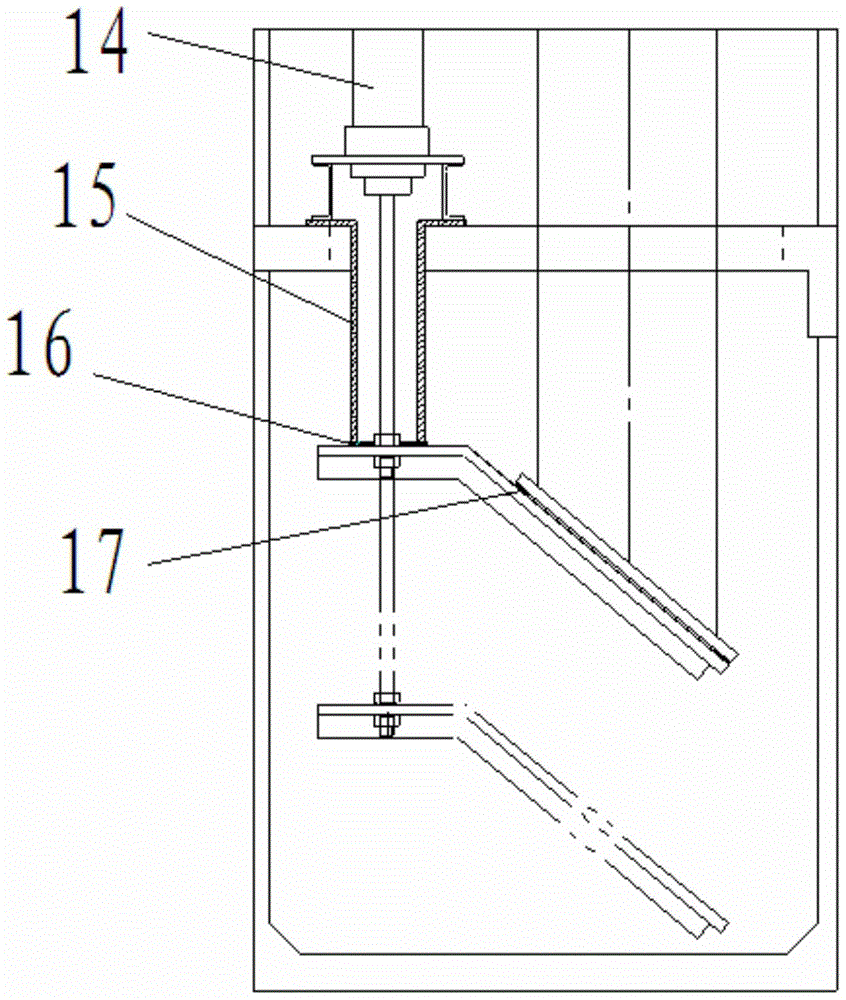

[0021] Such as figure 1 As shown, a wet desulfurization pulping system includes a limestone powder bin 1 and a pulping tank 5, the limestone powder bin 1 is fixed on the ground 6 through steel structure legs 10, and the pulping tank 5 is set on the limestone Vertically below the powder bin, a weighing rotary feeder 3 is provided between the limestone powder bin 1 and the pulping tank 5, the lower part of the limestone powder bin 1 is connected with the blanking bin 13, and the lower part of the blanking bin 13 is provided with The flapper valve or gate valve 2, the lower part of the flapper valve or gate valve 2 is provided with a lower flange 7, the upper part of the weighing rotary feeder 3 is provided with an upper flange 8, and the flapper valve or gate valve 2 It is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com