Large-scale efficient automatic batching system

An automatic batching, large-scale technology, applied in the field of large-scale and efficient automatic batching systems, can solve the problems of high investment in batching automation systems, unfavorable staff health, poor accuracy, etc., to improve batching efficiency and reactor utilization, improve Environmental and occupational hygiene levels, effects of improved accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

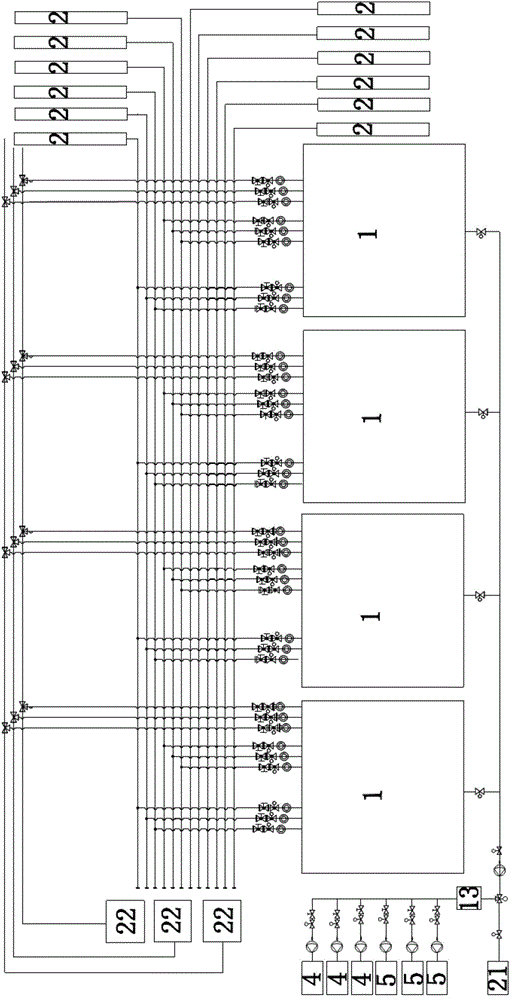

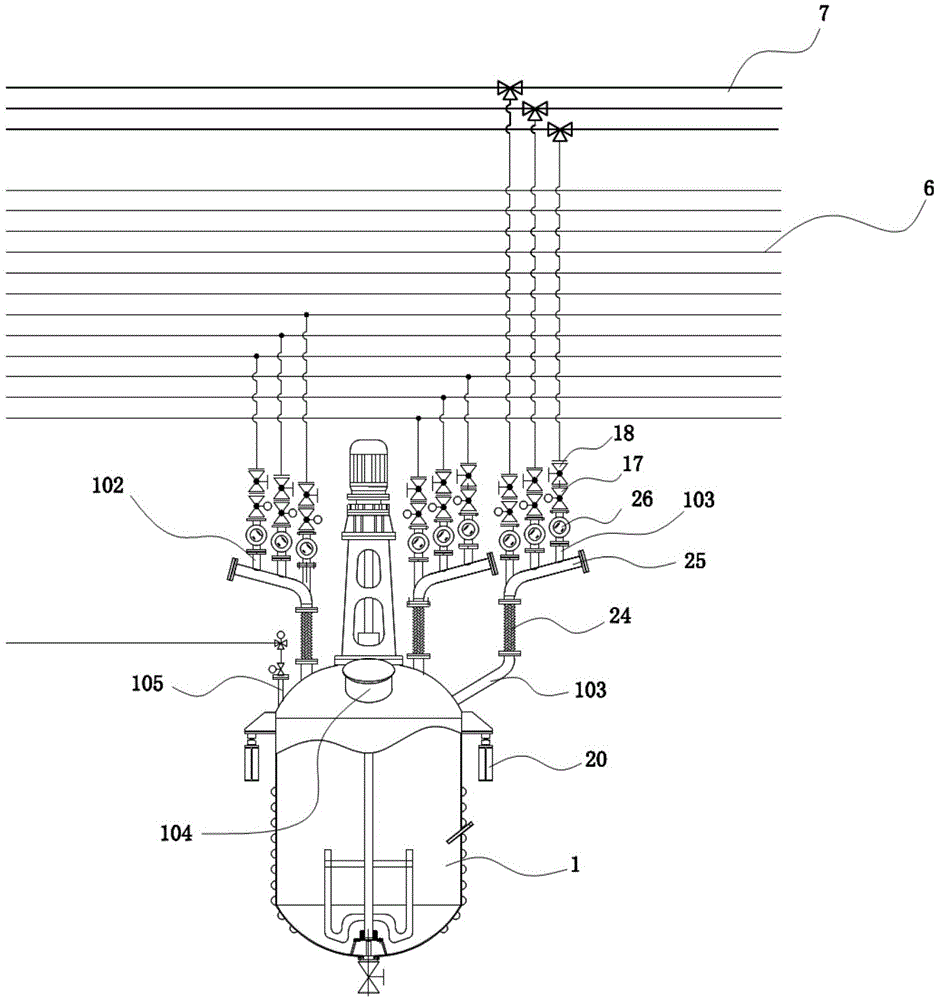

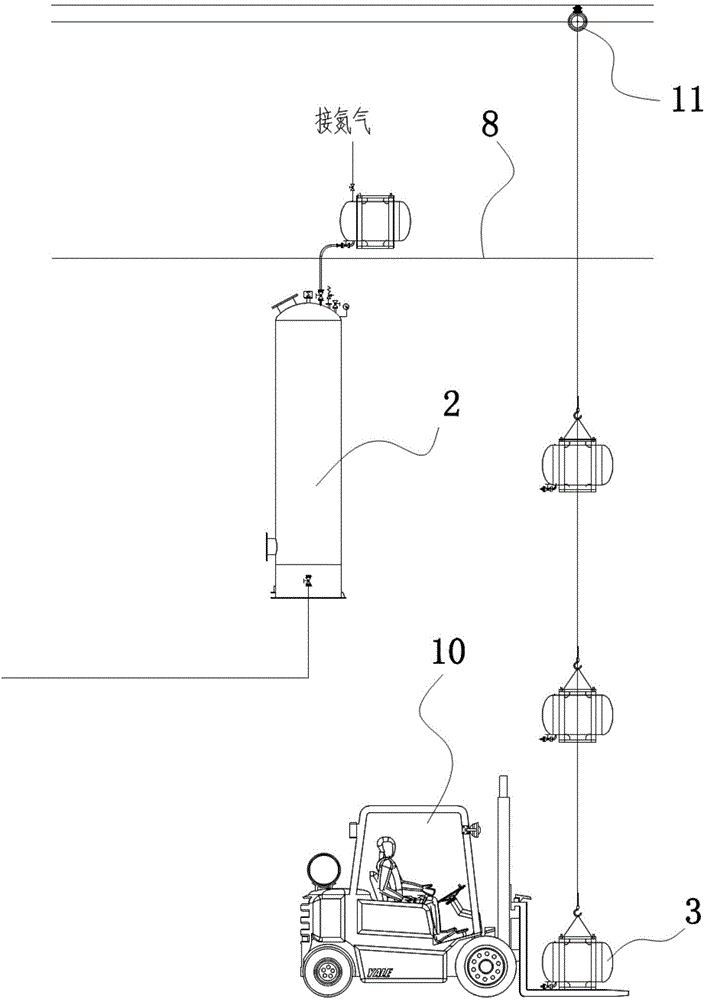

[0033] Referring to the accompanying drawings, a large-scale and efficient automatic batching system of the present invention includes a batching automatic control system, and a reaction kettle 1, a resin tank 2, a chemical storage tank 3, an auxiliary storage tank 4, a color paste storage tank 5 and a plurality of parallel powder material delivery pipeline 6 and a plurality of parallel liquid material delivery pipelines 7.

[0034] Reactor 1 is a plurality of side by side (depending on the type and scale of the product to be produced, the same below), each reactor is provided with a plurality of powder feed ports 101 and liquid feed ports 102, each powder feed port The feed port 101 and the liquid feed port 102 are connected to the corresponding powder material delivery pipeline 6 and liquid material delivery pipeline 7; the reaction kettle 1 is provided with a load cell 20 for weighing the weight of the added material.

[0035] Resin tank 2 is a plurality of side by side, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com