Epoxy novolac coating for inner walls of food cans and preparation method of epoxy novolac coating

A technology of epoxy phenolic coatings and cans, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of high corrosion resistance of coating films, and achieve high safety, low energy consumption, and simple production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0019] The preparation method of epoxy phenolic paint for food can inner wall of the present invention comprises the steps:

[0020] (1) Synthesis of 6009 epoxy resin: Add 720kg128 epoxy resin, 270kg bisphenol A and 110kg imidazole to a 500L reactor, heat the mixture to 180-190°C for 45-90min, after the reaction, cool and pulverize to obtain 6009 epoxy resin.

[0021] (2) Preparation of 6009 epoxy resin solution: Add 400kg of solid 6009 epoxy resin and 600kg of mixed solvent into a 1000L reactor, heat the mixture to 130°C, reflux and dehydrate for 60min, keep it warm for 2h, and finally cool down to 40°C before discharging Filter to obtain 6009 epoxy resin solution.

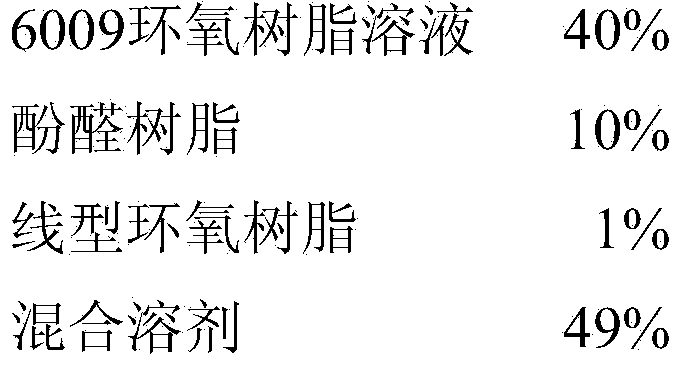

[0022] (3) Synthesis of coating: Add 400kg of 6009 epoxy resin solution prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com