Low-temperature lubricating grease composition and preparation method thereof

A technology of low-temperature lubrication and composition, which is applied in the field of lubricating grease, can solve the problems of increased wear, increased movement resistance between friction parts in lubrication parts, poor flow performance, etc., and achieves energy saving, stable product quality, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

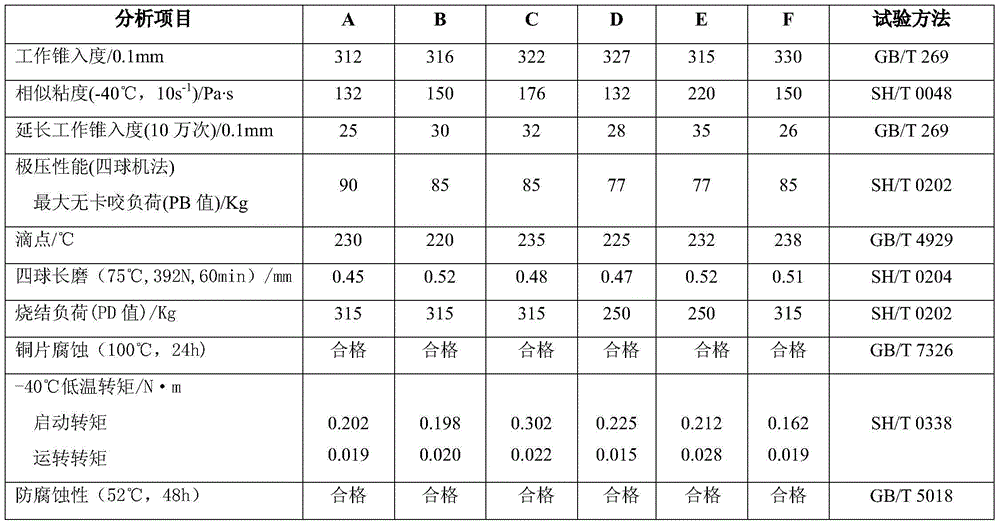

Examples

Embodiment 1

[0031] Base oil (PAO): 84%;

[0032] Stearic acid: 3.73%

[0033] Lithium hydroxide monohydrate: 0.27%

[0034] Bentonite: 4.0%

[0035] Extreme pressure agent: 2.0%;

[0036] Rust inhibitor: 2.0%;

[0037] Antiwear agent: 2.0%;

[0038] Antioxidant: 2.0%

[0039] Add 3.73% stearic acid to 42% base oil (PAO and trimellitate at a ratio of 1:1, the base oils used below are prepared according to this ratio), mix and heat to 85°C, after the stearic acid dissolves, Add 0.27% lithium hydroxide monohydrate lye (water is 5 times that of lithium hydroxide monohydrate), control the temperature at 90°C, and saponify for 0.5 hours; after the reaction, raise the temperature and drain water, raise the temperature to 130°C, and add 21% base oil Continue to heat up to the highest temperature of 200°C, then add the remaining base oil, stir for five minutes, take it out and cool it down to about 130°C, add 4.0% organic bentonite, and stir quickly at constant temperature for 1 hour. After...

Embodiment 2

[0041] Base oil (150DN): 80%;

[0042] Stearic acid: 6.72%

[0043] Lithium hydroxide monohydrate: 0.78%

[0044] Bentonite: 2.5%

[0045] Extreme pressure agent: 2.0%;

[0046] Rust inhibitor: 4.0%;

[0047] Antiwear agent: 2.0%;

[0048] Antioxidant: 2.0%

[0049]Add 6.72% stearic acid to 40% base oil (150DN), mix and heat to 95°C, after the stearic acid dissolves, add 0.78% lithium hydroxide monohydrate lye (water is 5 times that of lithium hydroxide monohydrate ), the temperature was controlled at 92°C, and the saponification reaction was carried out for 1 hour; after the reaction was completed, the temperature was raised to drain water, the temperature was raised to 130°C, and 20% heating oil was added; the temperature was continued to rise to the highest temperature of 210°C, and then the remaining base oil was added, stirred for five minutes, and the temperature was taken out to cool down To 130°C, add 2.5% organic bentonite, and stir rapidly at constant temperatu...

Embodiment 3

[0051] Base oil (trimellitate): 76%;

[0052] Stearic acid: 7.87%

[0053] Bentonite: 3.0%

[0054] Lithium hydroxide monohydrate: 1.13%

[0055] Extreme pressure agent: 3.0%;

[0056] Rust inhibitor: 4.0%;

[0057] Antiwear agent: 3.0%;

[0058] Antioxidant: 2.0%

[0059] Add 7.87% stearic acid to 38% base oil (trimellitate), mix and heat to 92°C, after the stearic acid dissolves, add 1.13% monohydrate lithium hydroxide lye (water is monohydrate hydroxide Lithium 5 times), the temperature is controlled at 93 ° C, saponification reaction for 1 hour; after the reaction is completed, the temperature is raised to drain, the temperature is raised to 130 ° C, and 19% heating oil is added; the temperature is continued to the highest temperature of 200 ° C, and then the remaining base oil is added and stirred for five minutes, take it out and cool down to 120°C, add 3.0% organic bentonite, and stir rapidly at constant temperature for 1 hour. After constant temperature, add ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com