Corrosion-resistant chimney lining structure and corrosion-resistant method for chimney

A chimney lining and anti-corrosion technology, applied in building construction, building maintenance, building types, etc., can solve problems such as structural damage of chimneys, and achieve the effects of reducing load-bearing burden, saving construction, and being lightweight, high-strength, and designable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

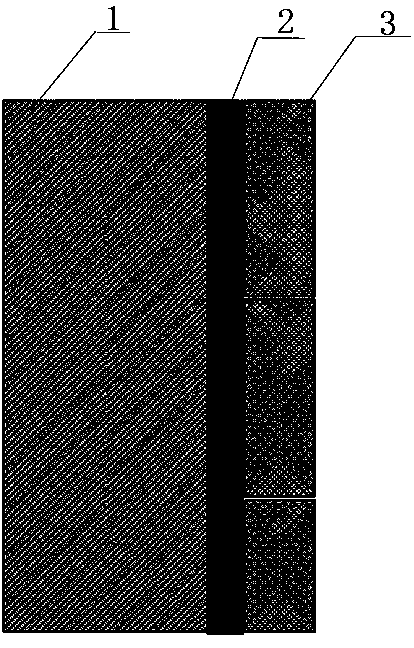

[0026] In the first aspect, the present invention provides a kind of anti-corrosion chimney lining structure and chimney anti-corrosion method, and its chimney is a new anti-corrosion chimney or a single-tube chimney under construction, and its structure includes in turn from outside to inside: reinforced concrete cylinder 1 , insulation layer 2, FRP lining 3, the FRP lining 3 adopts vitrified foam brick lining structure, the material adopts light vitrified foam brick, and forms an independent smoke exhaust structure as a whole, except for the FRP lining Parts other than 3 are only load-bearing structures.

[0027] The construction scheme of the newly-built anti-corrosion chimney is constructed according to conventional technology, and only the original anti-corrosion inner layer of the chimney in the prior art is replaced with a vitrified foam brick lining.

[0028] For the newly built anti-corrosion chimney, the innermost layer of the chimney is lined with vitrified foam bri...

Embodiment 2

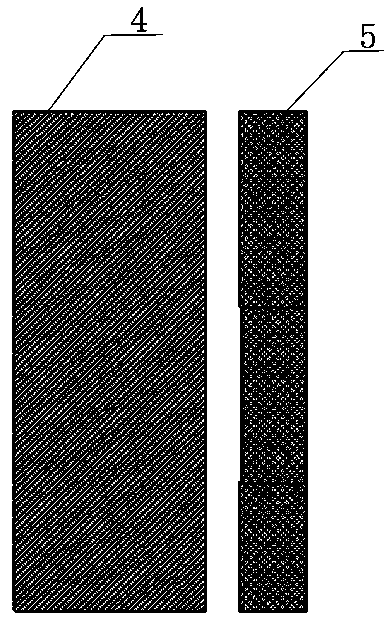

[0031] The present invention can also carry out anti-corrosion transformation on the existing single-tube chimney, which adopts the method of separating the flue gas from the original chimney 4, sets the original chimney 4 as a load-bearing structure, and adds vitrified glass to the innermost layer of the original chimney 4 Foam brick lining structure 5.

[0032] Described monotube chimney, its modification method comprises the steps:

[0033] (1) Pre-treat the inner wall of the single-tube chimney;

[0034] (2) A vitrified foam brick lining structure is added to the inner wall after pretreatment. The specific process is as follows:

[0035] a. Remove part of the lining at the corbel of the chimney, so that the corbel is partially exposed, so that the vitrified foam brick lining can be supported on the corbel in sections;

[0036] b Anti-corrosion treatment on the corbel: Wrap the corbel with lightweight vitrified foam bricks and fully expose it.

[0037] The method include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com