Ceramic bearing and nuclear power pump equipped with ceramic bearing

A ceramic bearing and ceramic technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of dry wear resistance, thermal shock resistance and impurity resistance at the same time, and achieve good resistance. The effect of impurity conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

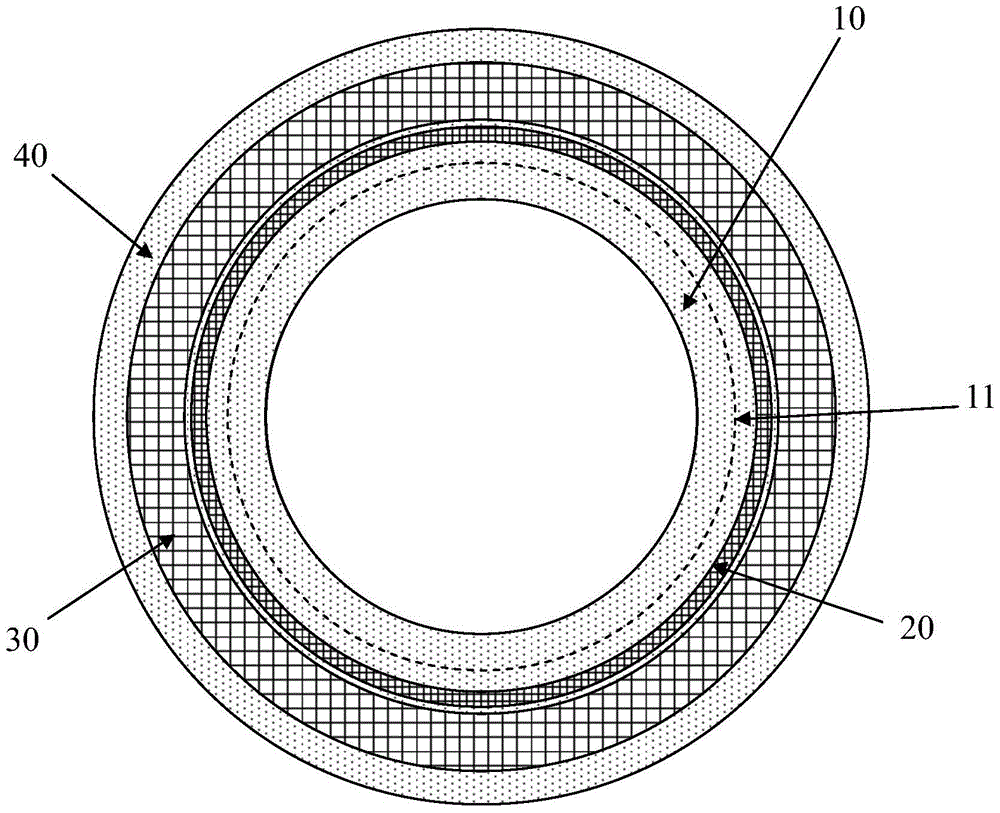

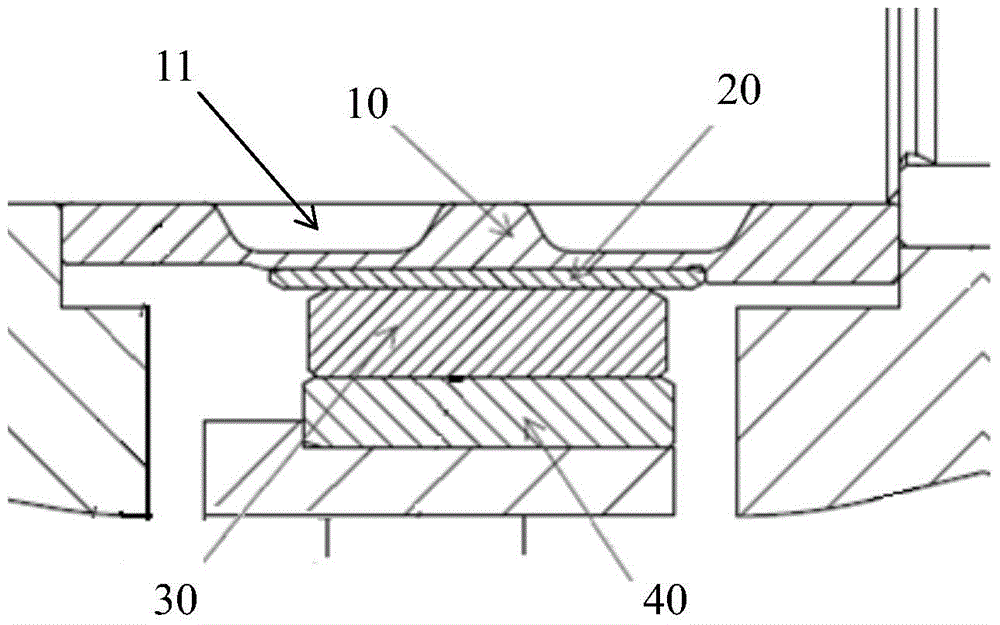

[0030] Such as figure 1 , figure 2 As shown, the ceramic bearing provided by the present invention involves four main parts, wherein the rotating parts are metal bushing 10 and ceramic bushing 20, both of which are installed through interference fit; the fixed parts are ceramic outer ring 30 and metal shell 40 , the two are also assembled by interference fit.

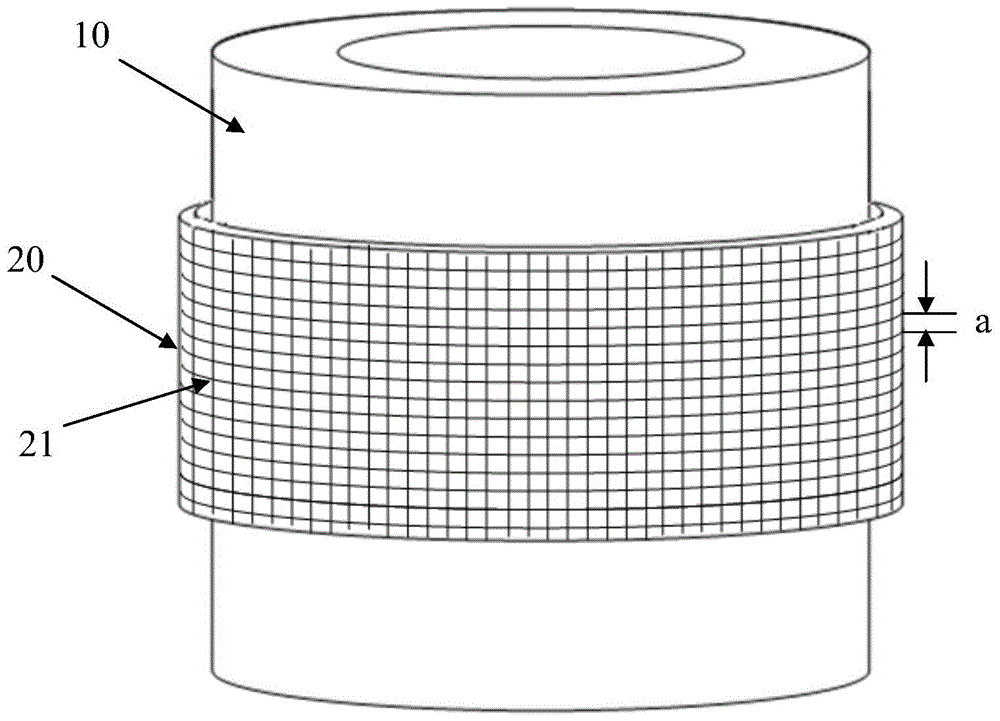

[0031] Such as image 3 As shown, the ceramic bushing 20 surrounds the outer side of the metal bushing 10 and is approximately at the middle position in the axial direction of the metal bushing 10, that is, the top and bottom of the metal bushing 10 respectively extend beyond the ceramic bushing. 20 top and bottom. The positions of the ceramic outer ring 30 and the metal shell 40 correspond to the axial position of the ceramic bushing 20; the metal shell 40 is arranged on the outer side of the ceramic outer ring 30, and the ceramic outer ring 30 The inner side of the corresponding to the outer side of the ceramic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com