Compound firebrick

A refractory brick and composite technology, applied in the direction of furnaces, layered products, chemical instruments and methods, etc., can solve the problems of lack of heat conduction, difficulty in meeting production, difficulty in storage, etc., to achieve stable heat transfer, prolong service life, The effect of promoting efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

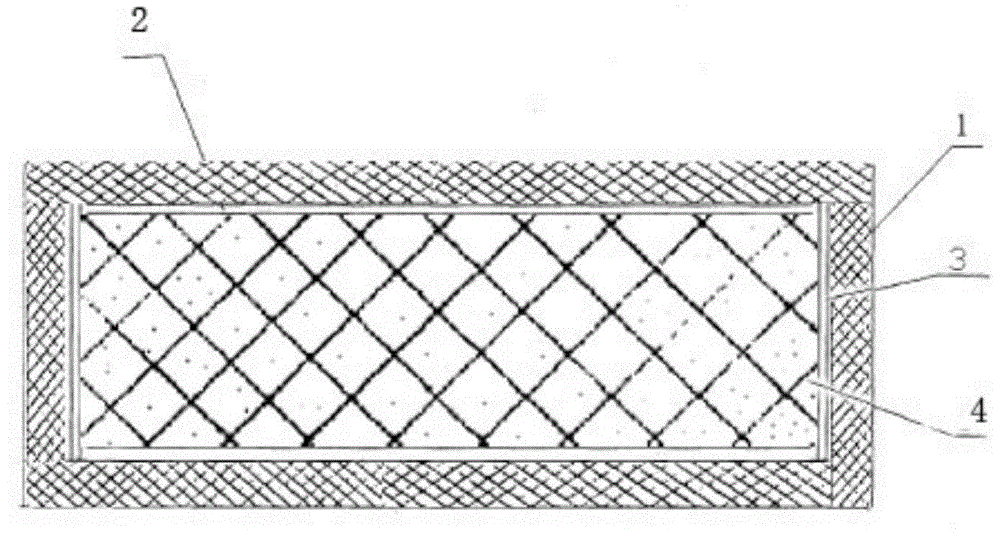

[0012] Such as figure 1 As shown, a composite refractory brick includes a brick body, the brick body is rectangular, and the brick body is divided into three parts, which are the outermost refractory material 1, the asbestos mesh layer 3 in the middle layer, and the inner layer Layer of insulation material2. The inner layer insulation material 2 is provided with mullite particles 4,

[0013] The thickness of the asbestos mesh layer 3 is about 3mm--5mm.

[0014] The outermost refractory material 1 is a lightweight high-temperature refractory material.

[0015] The heat first passes through the outermost layer of refractory material 1, and then passes through the asbestos mesh layer 3 to the inner layer of thermal insulation material 2. store it up.

[0016] The combination of refractory material 1 and inner layer insulation material 2 reduces heat loss and promotes efficient use of energy. The asbestos mesh layer 3 in the middle makes heat transfer stable and evenly distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com