Welding residual stress measuring method based on XJTUOM three-dimensional optical surface scanning and measuring system

A technology of three-dimensional optics and residual stress, applied in the field of engineering, can solve problems such as inability to realize full-field measurement, time-consuming, and prone to deviations

Inactive Publication Date: 2015-02-25

XI AN JIAOTONG UNIV

View PDF6 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

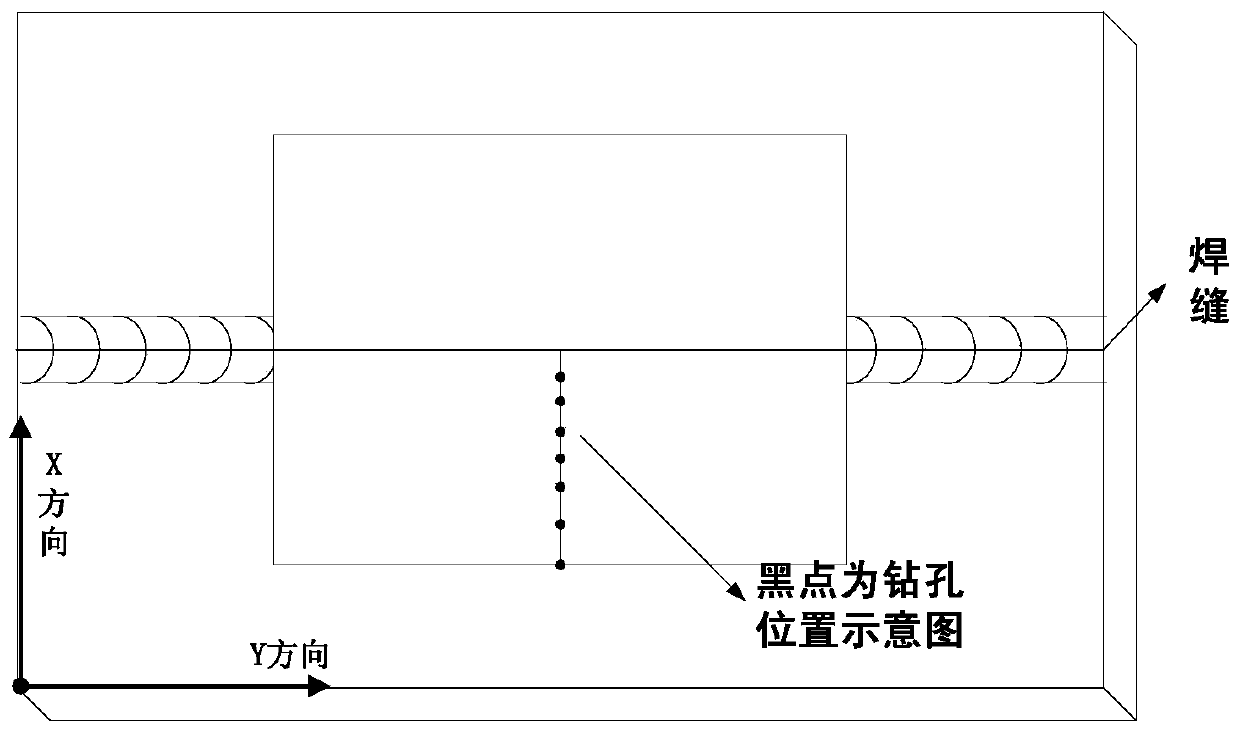

In addition, since the blind hole method has strict requirements on the flatness of the workpiece surface and the position of the drilled hole, and most importantly, it cannot achieve full-field measurement. In the actual process, the process is often cumbersome and time-consuming. The main Because the position of the drilled hole is prone to deviation, the accuracy will be seriously affected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

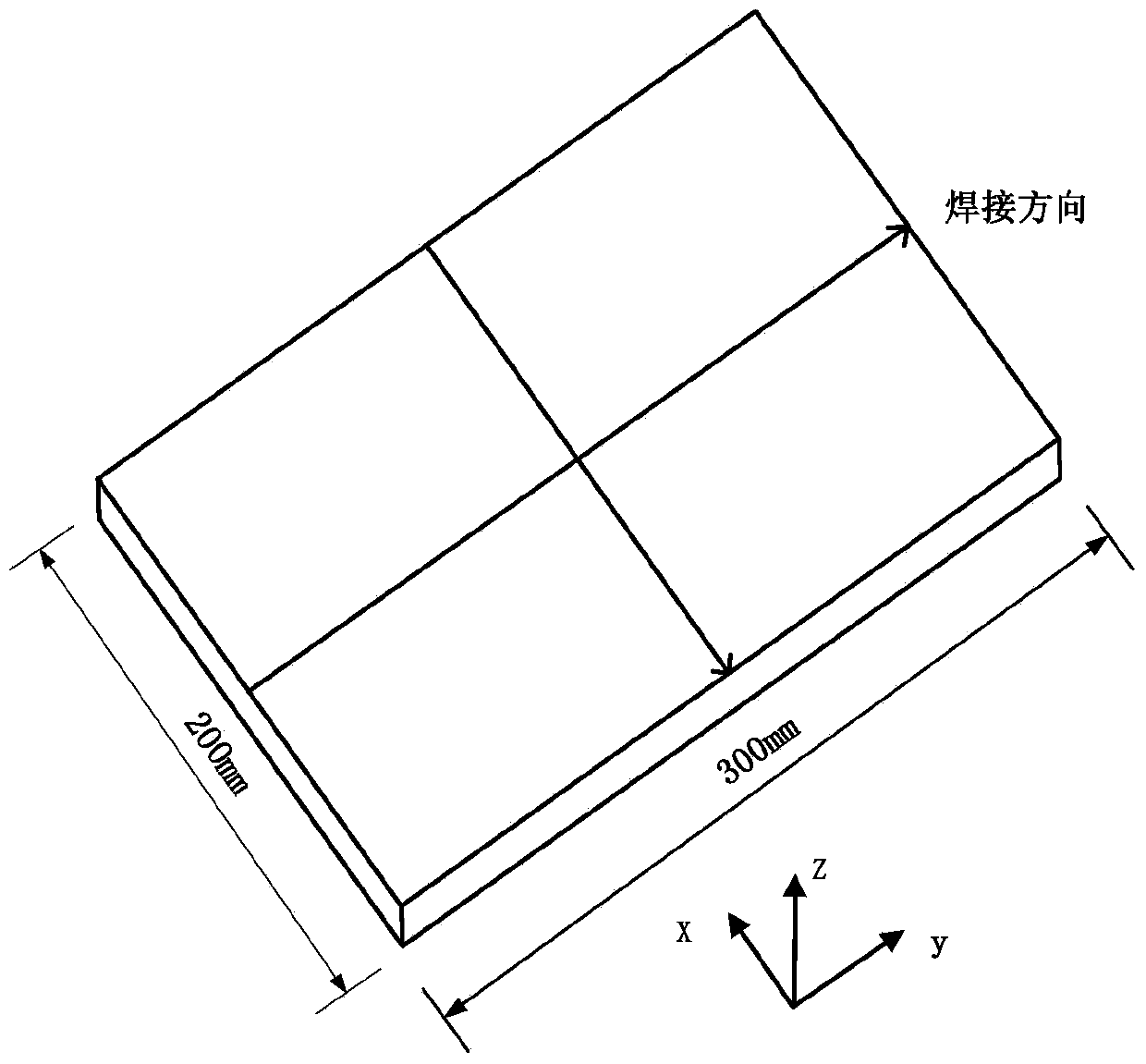

[0079] In this example, the selected welding method is GTAW plate surfacing welding, the walking speed of the welding torch is controlled by the welding robot, the welding speed is 5mm / s, the flow rate of argon gas is 10L / min, and the tungsten electrode used is Φ3.2mm The thoriated tungsten electrode has a tungsten extension length of 4mm. The 300×200×2 (mm) Q235B test plate is welded with a welding current of 110A.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

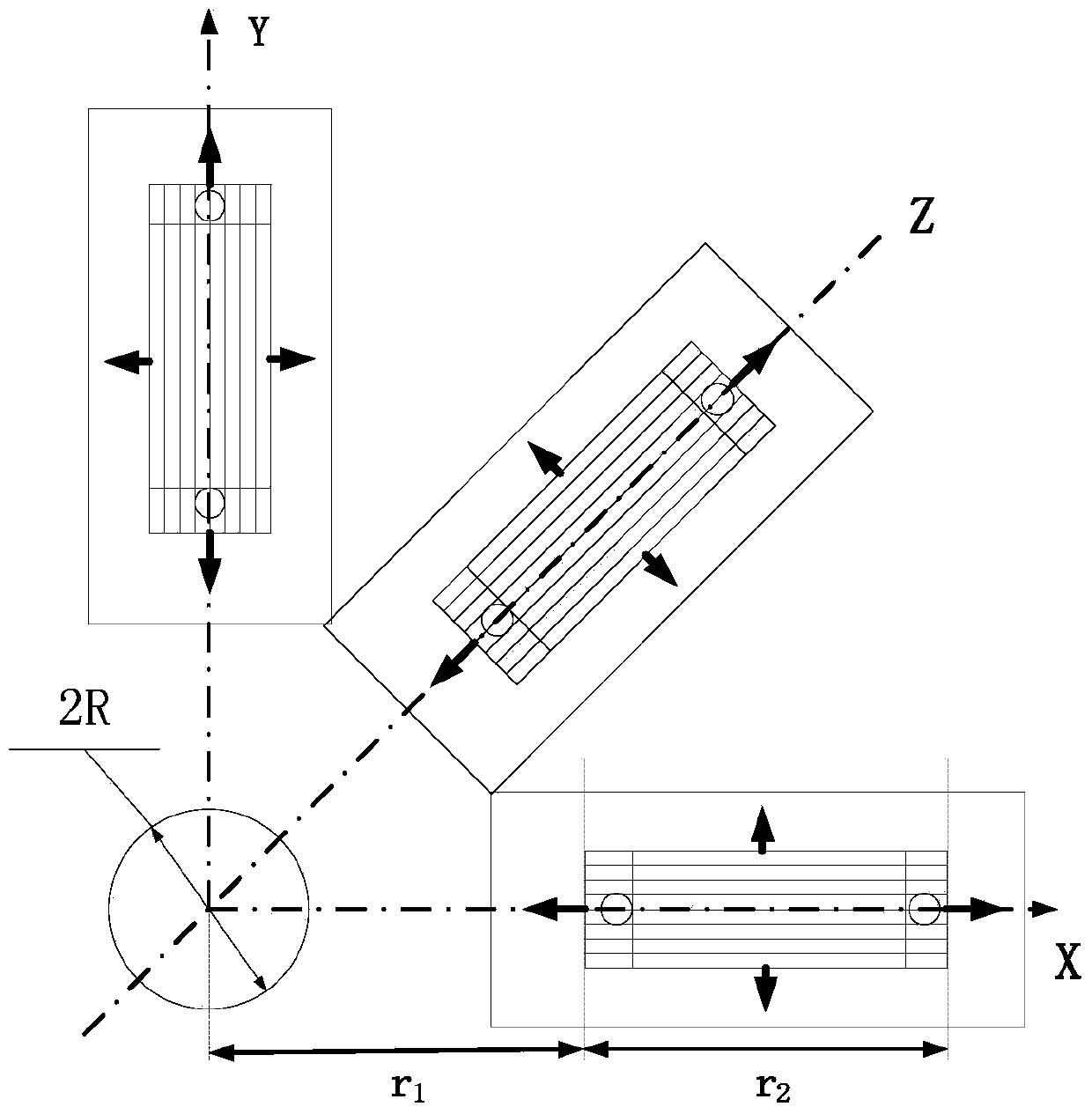

The invention discloses a welding residual stress measuring method based on an XJTUOM three-dimensional optical surface scanning and measuring system. According to the method, on the basis of an original small-hole method measuring principle, an experimental method is greatly changed, the XJTUOM three-dimensional optical surface scanning system is utilized, different breadth can be quickly measured under an overall coordinate system of a mark point, multi-vision scanning point cloud is automatically spliced to the overall coordinate system of the mark point, workpieces of different accuracy and sizes can be measured, the welding residual stress measuring method is suitable for the workpieces ranging from dozens of millimeters to one hundred meters in size, multi-point measuring can be conducted, the stress distribution states of all measuring points can be analyzed conveniently, and the method is convenient to operate and high in measuring efficiency. Tested by the welding residual stress measuring test of a Q235B thin steel sheet, the method is relatively accurate in measuring result.

Description

technical field [0001] The invention relates to a method for testing residual stress in the engineering field, in particular to a method for measuring welding residual stress based on optical surface scanning technology XJTUOM. Background technique [0002] The residual stress of welding is the uneven temperature field caused by the local high temperature of the weldment when the material is welded, and the welding center can reach more than 1500 °C. However, these temperature stresses will continue to change with time and temperature. However, the parts with high welding stress will reach the yield strength of the material and undergo plastic deformation, so the material will remain after cooling. The stress in the weldment is called welding residual stress. [0003] In engineering applications, welding residual stress is quite complex in actual conditions, and the magnitude and distribution of the stress vary with the shape, size, and welding method of the welded componen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01L1/22G01L1/24G01B11/25

Inventor 殷咸青杨涵鑫

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com