Diffusion type brightened reflecting film and backlight device

A reflective film and diffused technology, which is applied in the field of diffused brightening reflective films and backlight devices, can solve the problems of not considering the brightness, the brightness of the backlight source is not high, and the diffusion layer is not considered, so that it is not easy to be scratched and reduces Use amount, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

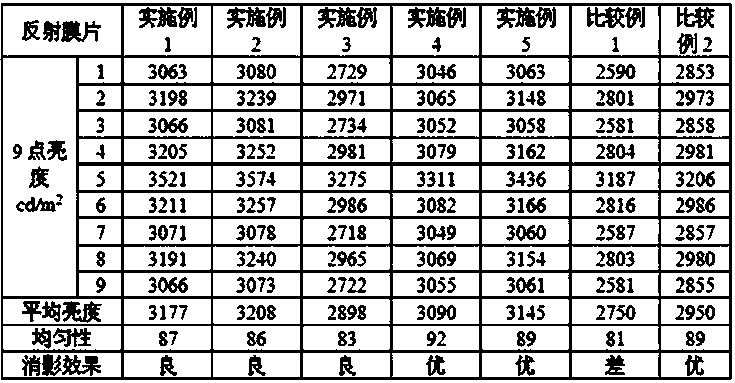

[0035] According to the material proportions in Table 1 and Table 2, the brightness-enhancing diffusion layer coating liquid and the anti-adhesion layer coating liquid were respectively obtained by stirring. The above coating liquids were respectively coated on both sides of the reflective substrate layer with a thickness of 188 μm and a reflectivity of 98%, and then cured and formed. The number of diffused particles in the coating was controlled to be about 10,000 per square millimeter by metering, and the thicknesses were respectively formed. The 13μm brightness-enhancing diffusion layer, the 3μm-thick anti-adhesion layer, and the reflective substrate layer together form a diffusion-type brightness-enhancing reflection film.

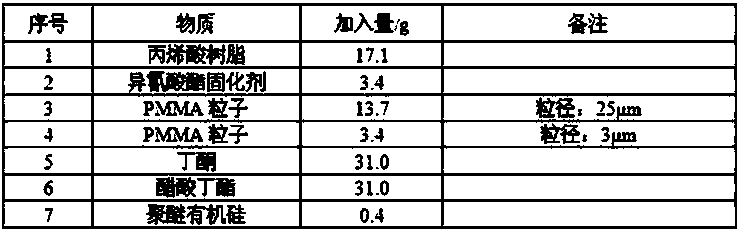

[0036] Table 1 Composition of coating solution for brightening diffusion coating

[0037]

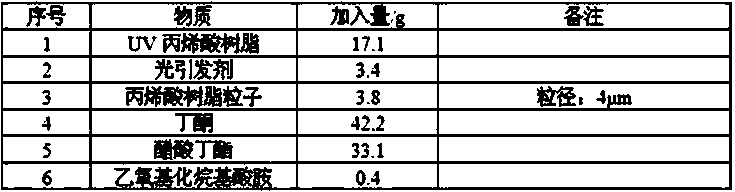

[0038] Table 2 Composition of anti-adhesion layer coating solution

[0039]

Embodiment 2

[0041]Use the same reflective substrate layer and the same anti-bonding layer as in Example 1, and the brightness-enhancing diffusion layer coating solution is formulated according to Table 3, and the number of diffusion particles in the coating is controlled to be about 10,000 per square millimeter by coating metering. , to obtain the diffusion-type brightness-enhancing reflective film of this embodiment. Wherein the brightness enhancing diffusion layer has a thickness of 13 μm.

[0042] Table 3 Composition of coating solution for brightening diffusion layer

[0043] .

Embodiment 3

[0045] Using the same reflective substrate layer and the same anti-bonding coating as in Example 1, the brightness-enhancing diffusion layer coating solution is proportioned according to Table 4, and the number of diffusion particles in the coating is controlled to be 5000 per square millimeter by coating metering. Left and right, the diffusion-type brightness-enhancing reflective film of this embodiment is obtained. Wherein the brightness enhancing diffusion layer has a thickness of 8 μm.

[0046] Table 4 Composition of coating solution for brightening diffusion coating

[0047] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com