Automatic High Speed Stranding Machine

A stranding machine and high-speed technology, applied in the field of stranding machines, can solve the problems of being unable to meet the needs of rapid and diversified markets, increasing production costs, and complicated replacement procedures, etc. The effect of high work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

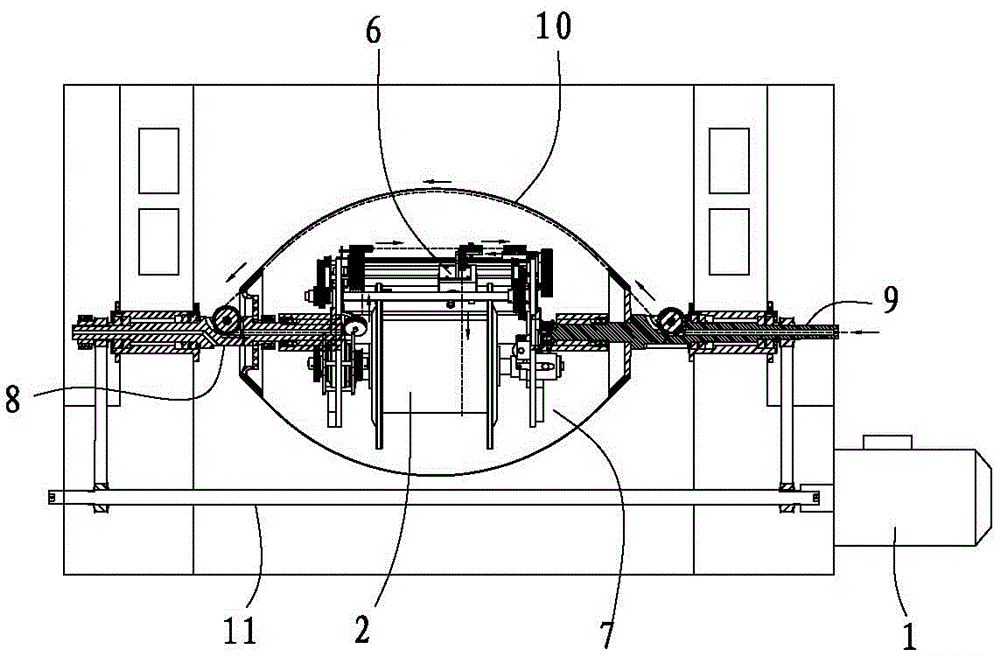

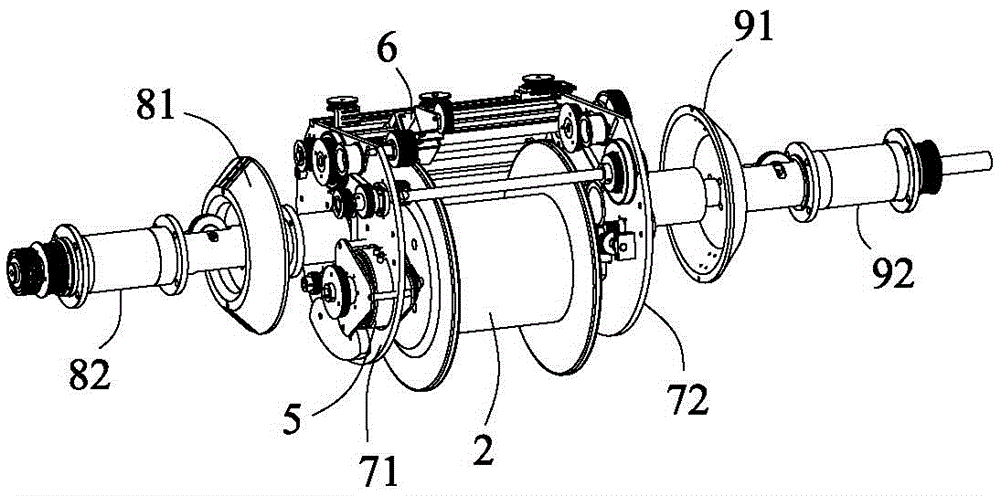

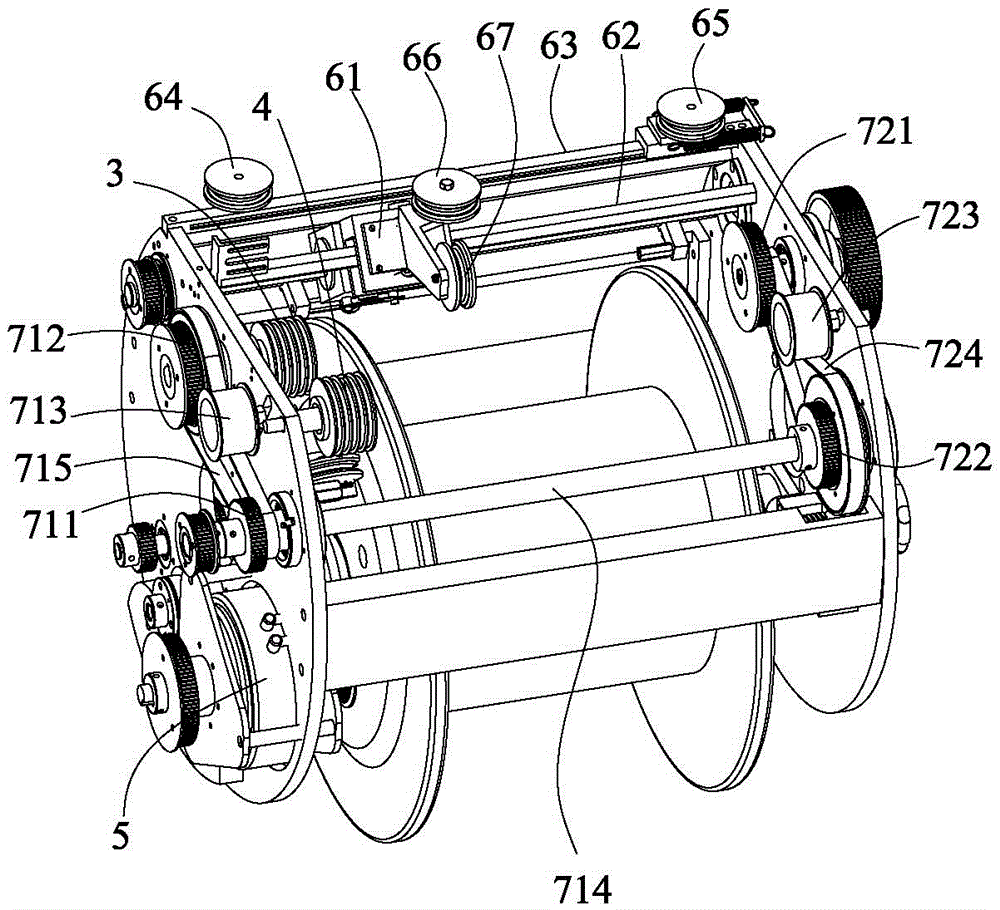

[0016] see Figure 1 to Figure 4 , an automatic high-speed stranding machine provided in this embodiment, which includes a high-speed servo motor 1, a bobbin 2, a variable drawing wheel 3, a fixed drawing wheel 4, a magnetic powder clutch 5, a wire arrangement mechanism 6, a bobbin seat 7 and settings The left threading rotating shaft 8 and the right threading rotating shaft 9 symmetrically arranged on both sides of the bobbin seat 7, one end of the left threading rotating shaft 8 and the right threading rotating shaft 9 near the bobbin seat 7 are provided with turntables 81, 91, and the other end is provided with a high The precision bearing housings 82, 92, the turntable 81 and the turntable 91 are connected through the winch 10, and the high-speed servo motor 1 is connected with the left threading shaft 8 and the right threading shaft 9. Specifically, the high-speed servo motor 1 is connected with the Coupling shaft 11 is connected, and the two ends of this coupling shaft 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com