Tire power generation device

A technology for power generation devices and conductive devices, which is applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., and can solve the problems of small deformation of piezoelectric elements, low collected voltage, and To solve problems such as difficult methods, achieve the effect of reducing workload, reasonable structure and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

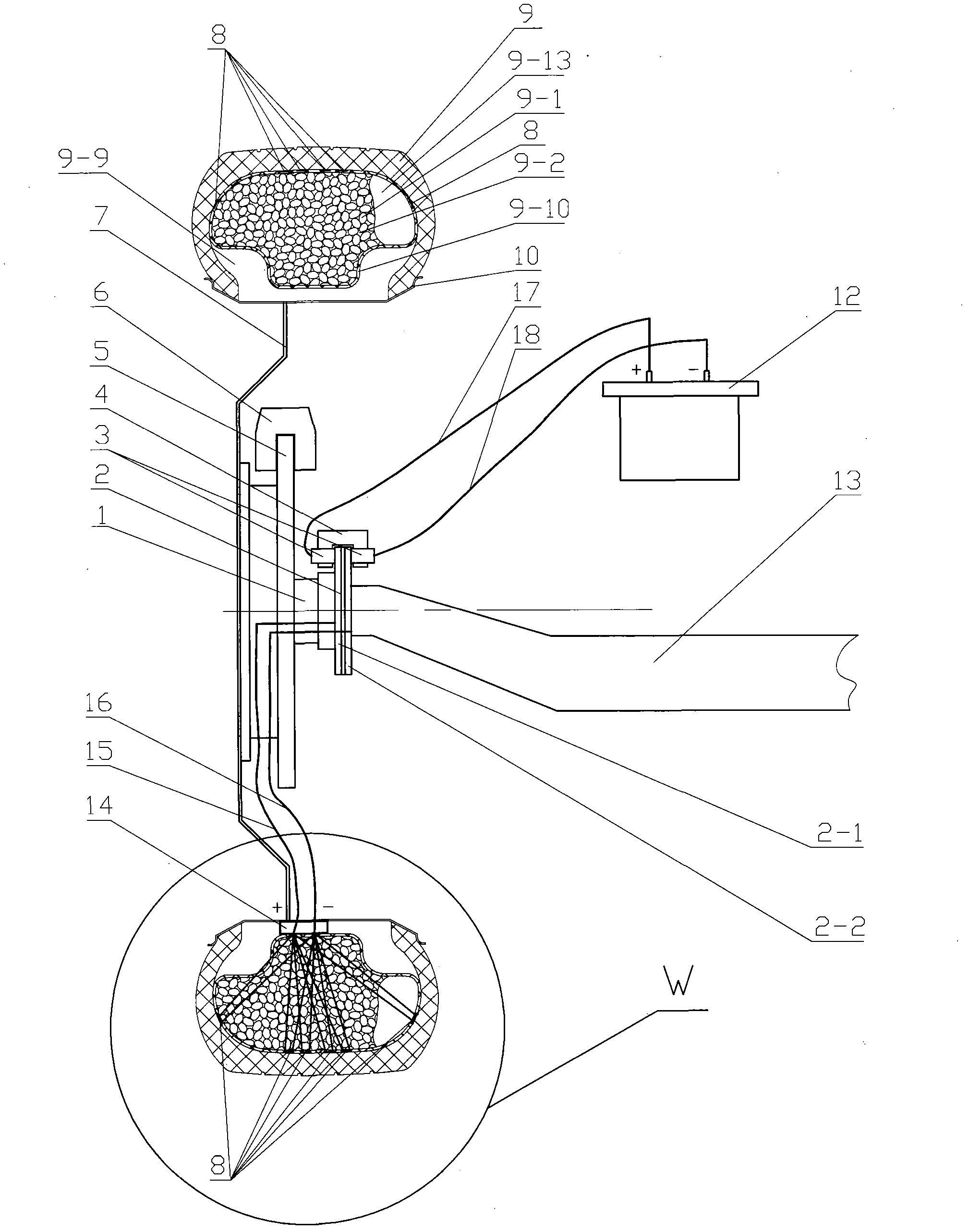

[0028] Specific implementation mode one: as figure 1 , 8 , 9, and 10, the tire power generation device includes a main shaft 1, a slip ring 2, a conductive device 4, a piezoelectric element 8, an outer tire 9, an elastic support body 9-13, an inner cavity 9-9, and a rubber tire 9 -10, rim 10, wire A15, wire B16, wire C17, wire D18, battery 12, vehicle frame 13 and electric energy converter 14.

[0029] The inside of the outer tire 9 is provided with a rubber tire 9-10, the cross section of the rubber tire 9-10 is a closed irregular ring, TPU is made into TPU foamed elastic particles 9-1, and the rubber tire 9-1 is put into the outer tire 9. Inside 10, countless TPU foamed elastic particles 9-1 are bonded together by adhesive or surface hot-melt technology, TPU foamed elastic particles 9-1 fill the space of rubber tire 9-10, TPU foamed elastic There are gaps 9-2 between the particles 9-1, and the gaps 9-2 are eliminated by pressurization or heating, or a small amount of gaps ...

specific Embodiment approach 2

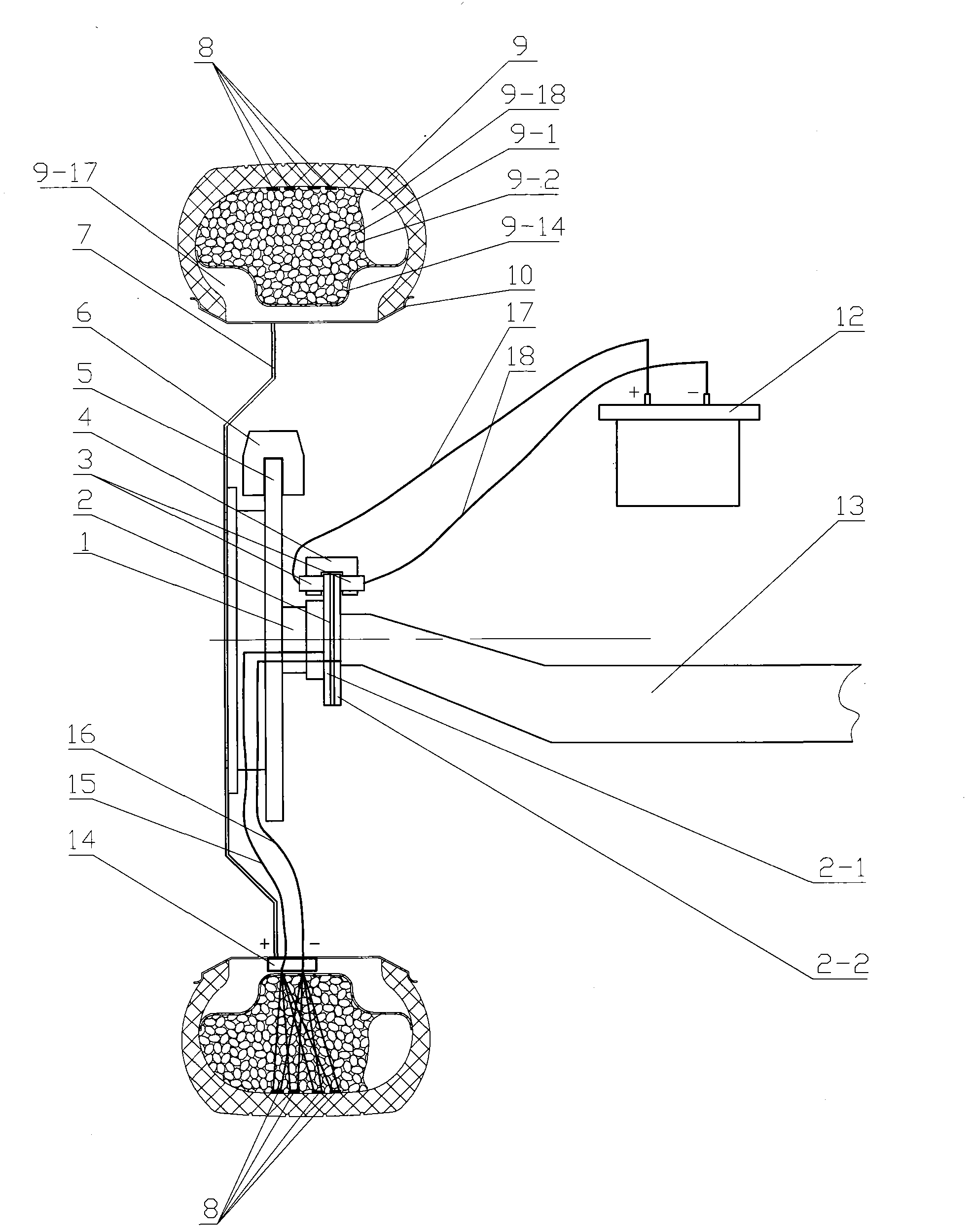

[0035] Specific implementation mode two: as figure 2 , 9 , 10, in this embodiment, the tire power generation device includes a main shaft 1, a slip ring 2, a conductive device 4, a piezoelectric element 8, an outer tire 9, an elastic support body A9-18, a rubber tire D9-14, Inner cavity G9-17, rim 10, lead A15, lead B16, lead C17, lead D18, accumulator 12, electric energy converter 14, rubber tire D9-14 and outer tire 9 are integrated with adhesive or hot-melt.

[0036] TPU is made into TPU foaming elastic particles 9-1, put into the inner part of the closed irregular ring formed by outer tire 9 and rubber tire D9-14, and countless TPU foaming elastic particles 9-1 are made of adhesive or surface heat It is bonded together by melting process, TPU foamed elastic particles 9-1 are filled with outer tire 9 and rubber tire D9-14 to form a closed irregular annular interior, and there are gaps between TPU foamed elastic particles 9-1 -2, TPU foamed elastic particles 9-1 are press...

specific Embodiment approach 3

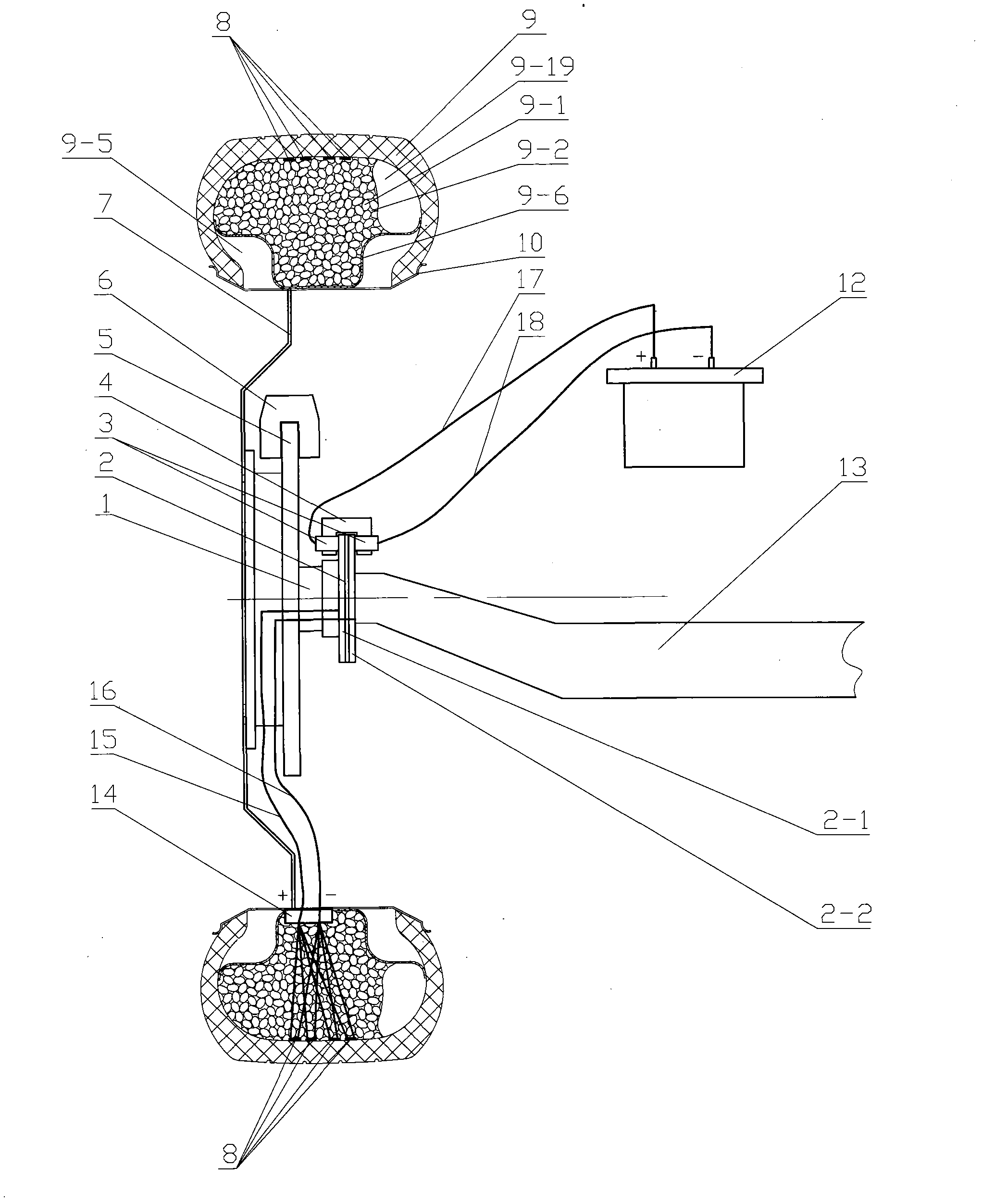

[0038] Specific implementation mode three: as image 3 , 9 , 10, in this embodiment, the tire power generation device includes a main shaft 1, a slip ring 2, a conductive device 4, a piezoelectric element 8, an outer tire 9, an elastic support body B9-19, a rubber tire B9-6, Inner chamber B9-5, rim 10, lead A15, lead B16, lead C17, lead D18, accumulator 12, electric energy converter 14, rubber tire B9-6 and outer tire 9 are integrated with adhesive or hot melt.

[0039] TPU is made into TPU foamed elastic particles 9-1, put into the closed ring-shaped interior of outer tire 9 and rubber tire B9-6, and countless TPU foamed elastic particles 9-1 are made of adhesive or surface hot-melt It is bonded together by the process, TPU foamed elastic particles 9-1 are filled in the closed ring surrounded by outer tire 9 and rubber tire B9-6, there are gaps 9-2 between TPU foamed elastic particles 9-1, TPU The foamed elastic particles 9-1 are pressurized or heated to eliminate the gap 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com