Preparation method of instant black fungus

A fungus and steaming technology, applied in food preparation, food science, application, etc., can solve the problems of short product shelf life, loss of nutritional value of food materials, low production efficiency, etc., so as to prevent bacteria from breeding, improve food safety, and improve production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of instant fungus, is characterized in that, comprises:

[0030] Step 1, sorting, classifying the soaked fungus raw materials according to their size and quality, and removing the impurities inside the raw materials;

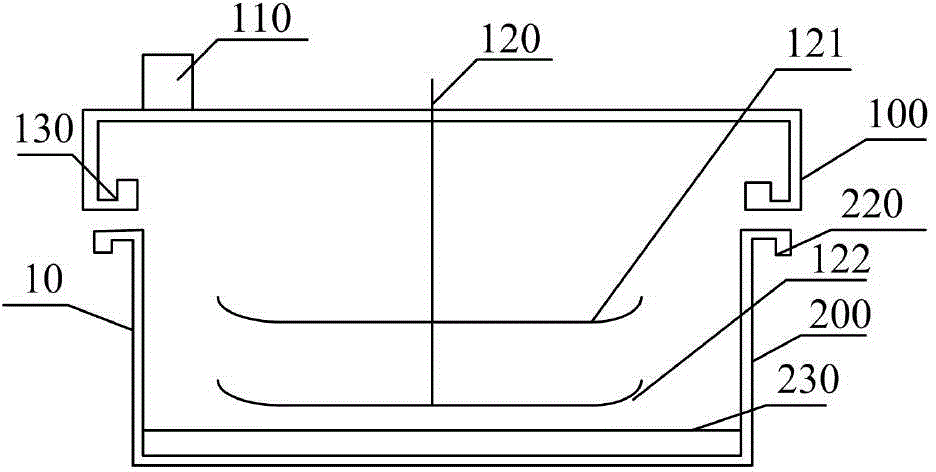

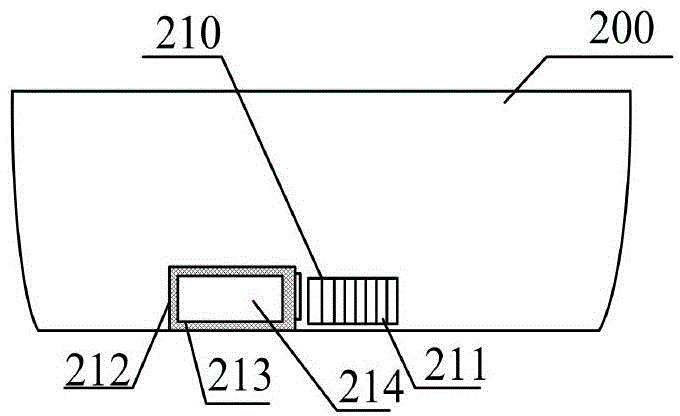

[0031] Step 2, cleaning, and put the sorted fungus into categories such as Figure 1-2 Cleaning is carried out in the cleaning box 10 shown;

[0032] Step 3, steaming, put the sorted fungus into the container, steam at 55-70 degrees under normal pressure for 4-8 minutes, the steam generating liquid of the steam is mountain spring water with a certain amount of salt , the weight percentage of the salt is 3%-6%;

[0033] Step 4: compress and dry, compress the steamed fungus, then control the compressed fungus at a temperature of -30 to -35 degrees to freeze, put it in a vacuum for dehydration and drying, so that the water content of the dehydrated fungus The rate is controlled at 3%-6%;

[0034] Step 5, encapsulation, weighi...

Embodiment 1

[0046] Step 1, sorting, classifying the soaked fungus raw materials according to their size and quality, and removing the impurities inside the raw materials;

[0047] Step 2, cleaning, put the sorted fungus into the cleaning box according to the category for cleaning;

[0048] Step 3, steaming, put the sorted fungus into the container, and steam at 55 degrees under normal pressure for 7 minutes, the steam generating liquid of the steam is mountain spring water with a certain amount of salt added, and the salt The weight percentage is 6%;

[0049] Step 4: compress and dry, compress the steamed fungus, then control the compressed fungus at a temperature of -30 degrees to freeze, put it in a vacuum for dehydration and drying, so that the moisture content of the dehydrated fungus is controlled at 3%;

[0050] Step 5, encapsulation, weighing and encapsulating the dried fungus, and then putting them into the convenience box together with the seasoning bag after vacuum sterilizati...

Embodiment 2

[0053] A kind of preparation method of instant fungus, is characterized in that, comprises:

[0054] Step 1, sorting, classifying the soaked fungus raw materials according to their size and quality, and removing the impurities inside the raw materials;

[0055] Step 2, cleaning, put the sorted fungus into the cleaning box according to the category for cleaning;

[0056] Step 3, steaming, put the sorted fungus into the container, and steam at 60 degrees under normal pressure for 6 minutes, the steam generating liquid of the steam is mountain spring water with a certain amount of salt added, and the salt The weight percentage is 4%;

[0057] Step 4: compress and dry, compress the steamed fungus, then control the compressed fungus at a temperature of -32 degrees to freeze, put it in a vacuum for dehydration and drying, so that the moisture content of the dehydrated fungus is controlled at 4%;

[0058] Step 5, encapsulation, weighing and encapsulating the dried fungus, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com