Cigarette filter tip and production method thereof

A technology for filters and cigarettes, applied in the fields of e-liquid filter elements, tobacco, applications, etc., can solve the problems of industrial production difficulties, micropore clogging, etc., and achieve good isolation and prevent membrane clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

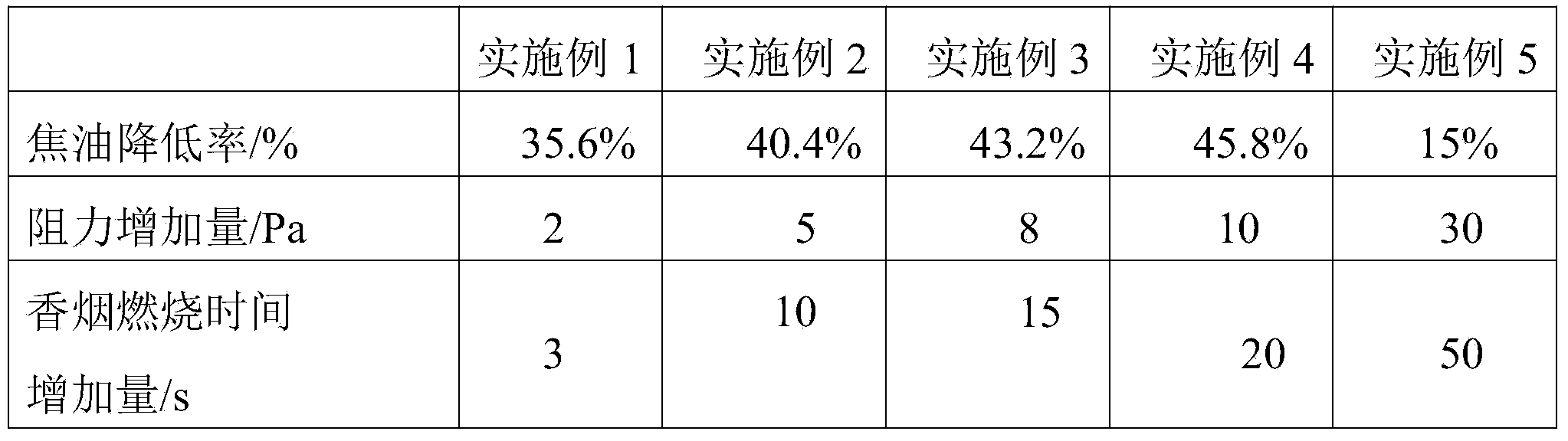

Embodiment 1

[0036] This embodiment provides a cigarette filter and its preparation method, the preparation steps are as follows:

[0037] (1) Set the thickness to 5mm and the weight to 150g / m 2 Porous PET support with a thickness of 0.3mm, a resistance of 3Pa, and 12g / m 2 Electret PP melt-blown non-woven fabric, microporous PET film with a thickness of 30μm, a thickness of 0.5mm, 50g / m 2 The PET skeleton non-woven fabric is sequentially laminated and compounded by hot pressing to obtain the filter section.

[0038] (2) The prepared filter section is combined with two sections of cellulose acetate, and the two sections of cellulose acetate are respectively located on both sides of the filter section to obtain a cigarette filter with a three-section structure.

Embodiment 2

[0040] This embodiment provides a cigarette filter and its preparation method, the preparation steps are as follows:

[0041] (1) Set the thickness to 8mm and the weight to 180g / m 2 Porous PET support with a thickness of 0.5mm, a resistance of 4Pa, and 20g / m 2 Electret PP meltblown non-woven fabric, microporous PET film with a thickness of 25μm, a thickness of 0.6mm, 60g / m 2 The PET skeleton non-woven fabric is sequentially laminated and compounded by hot pressing to obtain the filter section.

[0042](2) The prepared filter section is combined with two sections of cellulose acetate, and the two sections of cellulose acetate are respectively located on both sides of the filter section to obtain a cigarette filter with a three-section structure.

Embodiment 3

[0044] This embodiment provides a cigarette filter and its preparation method, the preparation steps are as follows:

[0045] (1) Set the thickness to 7mm and the weight to 160g / m 2 Porous PET support with a thickness of 0.5mm, a resistance of 4Pa, and 20g / m 2 Electret PP meltblown non-woven fabric, microporous PET film with a thickness of 30μm, a thickness of 0.8mm, 70g / m 2 The PET skeleton non-woven fabric is laminated sequentially with hot melt adhesive to obtain the filter section.

[0046] (2) The prepared filter section is combined with two sections of cellulose acetate, and the two sections of cellulose acetate are respectively located on both sides of the filter section to obtain a cigarette filter with a three-section structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com