Glass processing method and system

A processing method and technology of a processing system, applied in the field of glass processing, can solve the problems of low glass precision and efficiency, easy to break, etc., and achieve the effects of low cost, high precision and efficiency, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

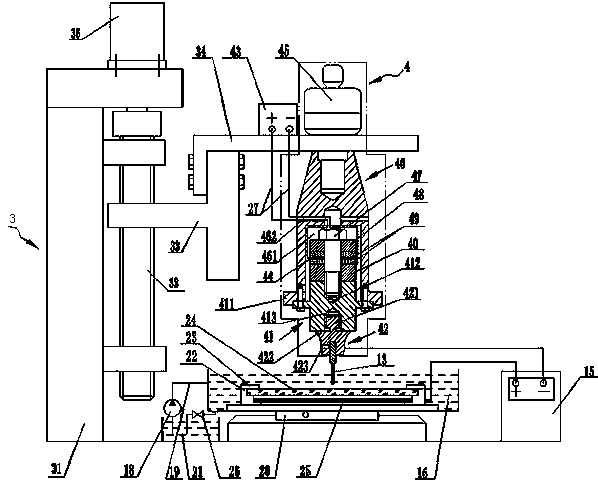

[0016] like figure 1 , a specific glass processing system implementing the method of the present invention has a tool electrode 13, the tool electrode 13 is connected to the ultrasonic vibrator 4, and is electrically connected to the negative electrode of the DC power supply 15. The tool electrode 13 will be used as a tool for processing micropores or microgrooves on the glass, and is arranged on an adjustment support 3 by the ultrasonic vibrator 4 connected thereto, so that the micropores of the glass can be adjusted by the adjustment support 3. Or during micro-groove processing, the feed movement in the depth direction can be done with the adjustment support 3 . A solution with electrochemical corrosion effect is placed in the chemical solution tank 16, and the processed glass workpiece 24 is fixed in the chemical solution tank 16 by the clamp 23 according to the upward direction of the processing surface and immersed in the chemical solution. The connected additional elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com