Manipulator for laying soldering terminals of diodes

A technology of solder sheet and manipulator, which is applied in the direction of tin feeding device, welding equipment, metal processing equipment, etc., can solve the problems of low frequency of vibrating solder sheet material, low rate of solder sheet penetration, low frequency of solder sheet material, etc. , to achieve the effect of shortening the time of laying solder sheet, improving efficiency and yield rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

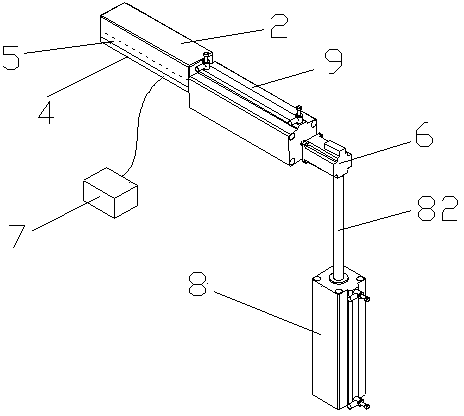

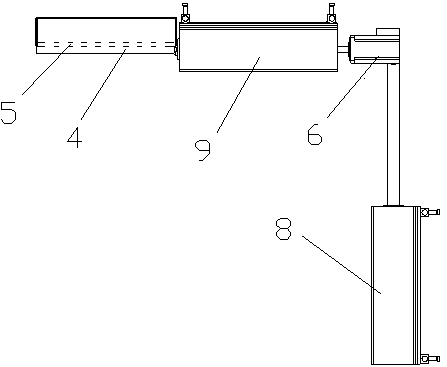

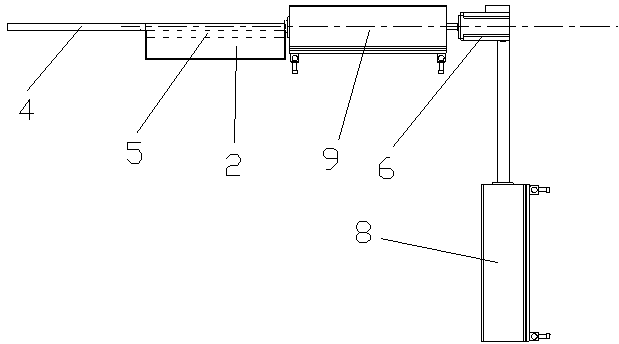

[0025] like Figure 1-5 As shown, a manipulator for laying diode solder sheets includes a support body extending along the height direction, and a hollow sealing material box 2 protruding laterally is provided on the support body. There are solder sheets stacked in the magazine 2, and there is also a solder sheet material plate 4 that can expand and contract laterally relative to the magazine 2 driven by a translation device. The solder sheet 4 is densely covered with 2000 recessed holes 42 , and a pipeline 44 connecting each recessed hole 42 and connecting the vacuum device is also provided. A motor 6 is also provided at one end of the material box 2 in the transverse direction, and the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com