Method and device for assembling bent legs of plug pieces

A technology of inserts and sockets, which is applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of high scrap rate and low process efficiency, and achieve the effects of improving efficiency, improving processing quality, and good health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples.

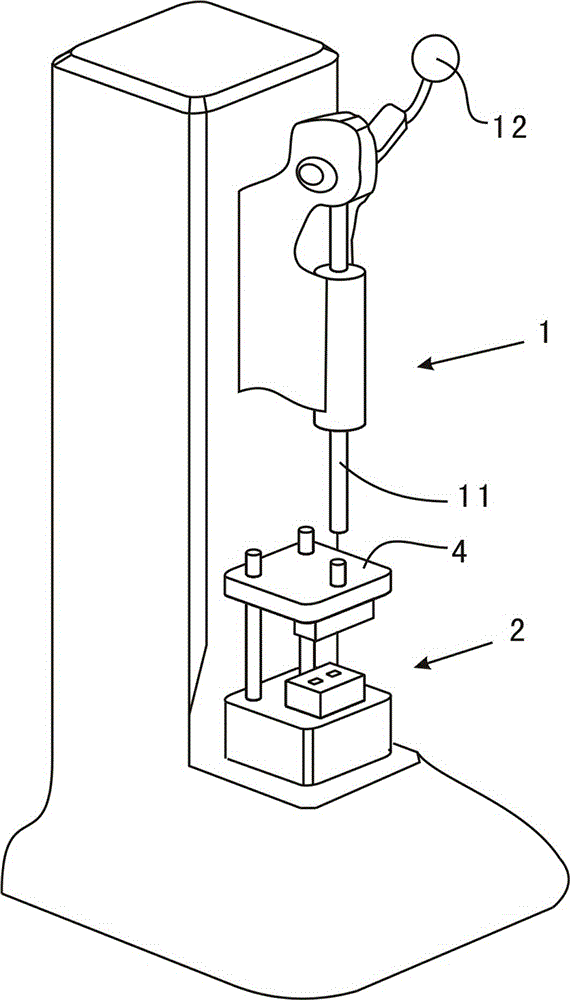

[0030] as attached Figure 1 ~ Figure 4 As shown, implementing a method of inserting the bent pin assembly includes the following steps:

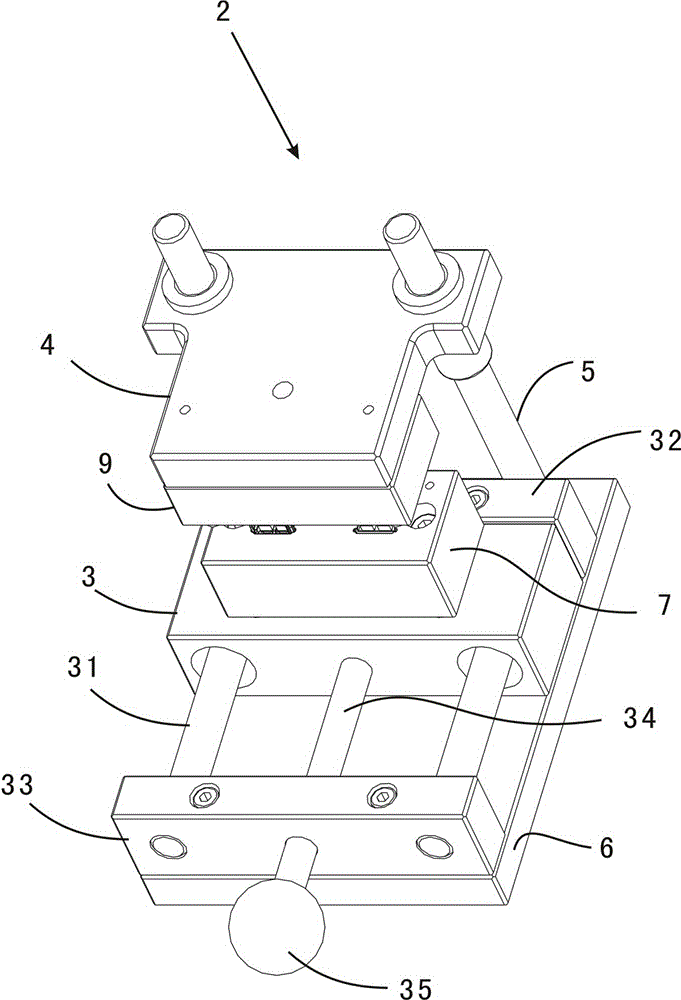

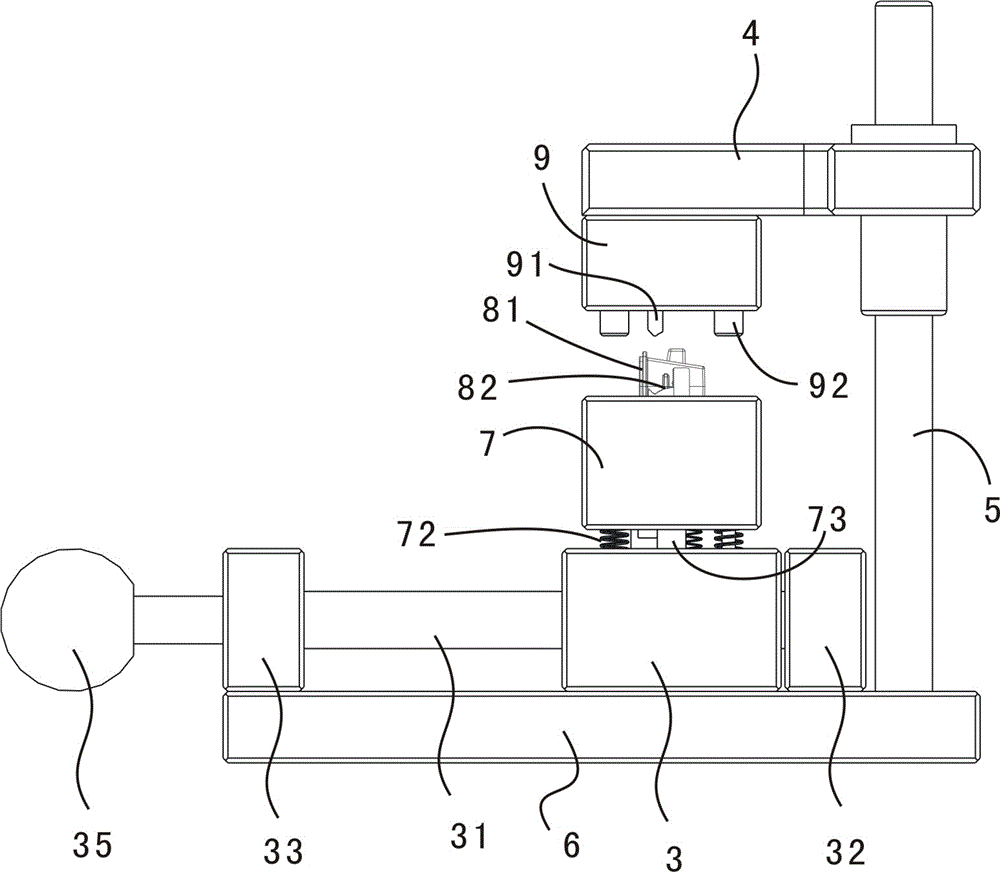

[0031] Step a, make the mold body 7, prepare at least two socket grooves on it, the shape of the bottom of the socket groove is the same as that of the inner side of the socket 81, just after the socket 81 is embedded in the socket groove, the outer surface of the socket 81 is exposed upwards The part where the metal insert 82 needs to be embedded;

[0032] Step b, then make the mold body base 3, and connect the lower mold body 7 with the mold body base 3 through the mold body sliding column 73; the mold body sliding column spring 72 is sleeved on the mold body sliding column 73, so that the lower mold body When the body 7 is forced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com