Plant-fiber elastic material with stiffening ribs

A technology of elastic materials and plant fibers, which is applied in the field of elastic materials, can solve the problems of long vulcanization time, large energy consumption, and low strength, and achieve the effects of shortened vulcanization time, low energy consumption, and strong compression resistance

Active Publication Date: 2015-03-04

GUIZHOU DAZIRAN TECH

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It turns out that the lamination process of all plant fiber elastic materials is carried out along the direction of the production line, resulting in irregular and large dimensional changes of the elastic material during subsequent vulcanization, and the strength of the elastic material in different directions is different, along the production line The strength in the direction is high, but the strength in the direction perpendicular to the production line is low. The mechanical properties of elastic materials are inconsistent in all directions. Therefore, elastic materials often have a series of quality problems such as collapse and bulging during use.

In addition, the plant fiber elastic material stacked according to the stacking method of the existing plant fiber elastic sheet has poor air permeability, and the water vapor inside the plant fiber elastic material is not easy to discharge during the vulcanization process, the vulcanization time is long, the energy consumption is large, and the cost is increased.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

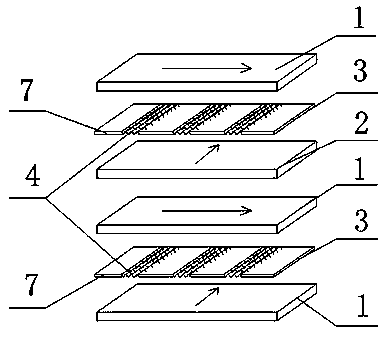

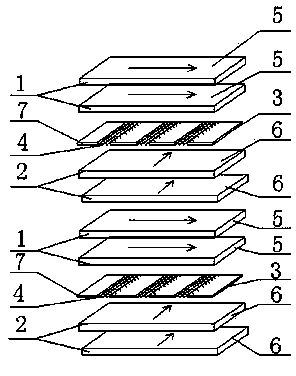

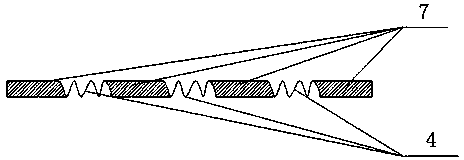

The invention discloses a plant-fiber elastic material with stiffening ribs. The plant-fiber elastic material is characterized by comprising longitudinal elastic sheets (1) and transverse elastic sheets (2) which are stacked in a manner of being intersected with the longitudinal elastic sheets (1), wherein skeleton layers (3) are arranged between the longitudinal elastic sheets (1) and the transverse elastic sheets (2), and the stiffening ribs (4) which serve as a skeleton of the elastic material and form through holes are arranged on the skeleton layers (3); the longitudinal elastic sheets (1) are the elastic sheets which come from along a production line, and the transverse elastic sheets (2) are the elastic sheets which come from vertical to a production line. The plant-fiber elastic material with the stiffening ribs has the advantages that the elasticity of the plant-fiber elastic material can be improved, the consumption of plant fibers can be lowered, the quality problems of bending and back breaking are avoided, the curing time is shortened, and the cost is reduced.

Description

technical field The invention relates to elastic materials, in particular to a plant fiber elastic material with reinforcing ribs. Background technique Elastic materials that save plant fibers are elastic materials made of natural plant fibers, including mountain palm, coconut shell, oil palm, hemp, bamboo, etc. . Chinese Patent No. 90100464.2 discloses a production method of plant fiber elastic material. The plant fiber filaments are crimped and blown into a three-dimensional distribution shape with air flow and then sprayed with glue to bond the nodes between the brown filaments to obtain a plant fiber elastic sheet. The elastic sheets are stacked to obtain an elastic material. Chinese Patent No. 200810302045.9 discloses a vulcanization method for plant fiber elastic materials, which vulcanizes stacked elastic sheets to improve the elasticity and durability of the elastic sheets. The technical solution is to first produce elastic sheets that are slightly wider than the e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B3/28B32B5/08B32B5/22

CPCB32B5/12B32B2307/51B32B2307/544B32B2479/00

Inventor 时小兵廖廷茂黄龙徐毅李长会

Owner GUIZHOU DAZIRAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com