Enhanced nitrogen and phosphorus removal process adopting mud water separation anaerobic/anoxic-membrane bioreactor

A membrane bioreactor, mud-water separation technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve poor mud-water separation effect, large number of reactors, cumbersome operation To achieve the effect of strengthening nitrification effect and denitrification phosphorus removal efficiency, improving treatment efficiency and ensuring the growth environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

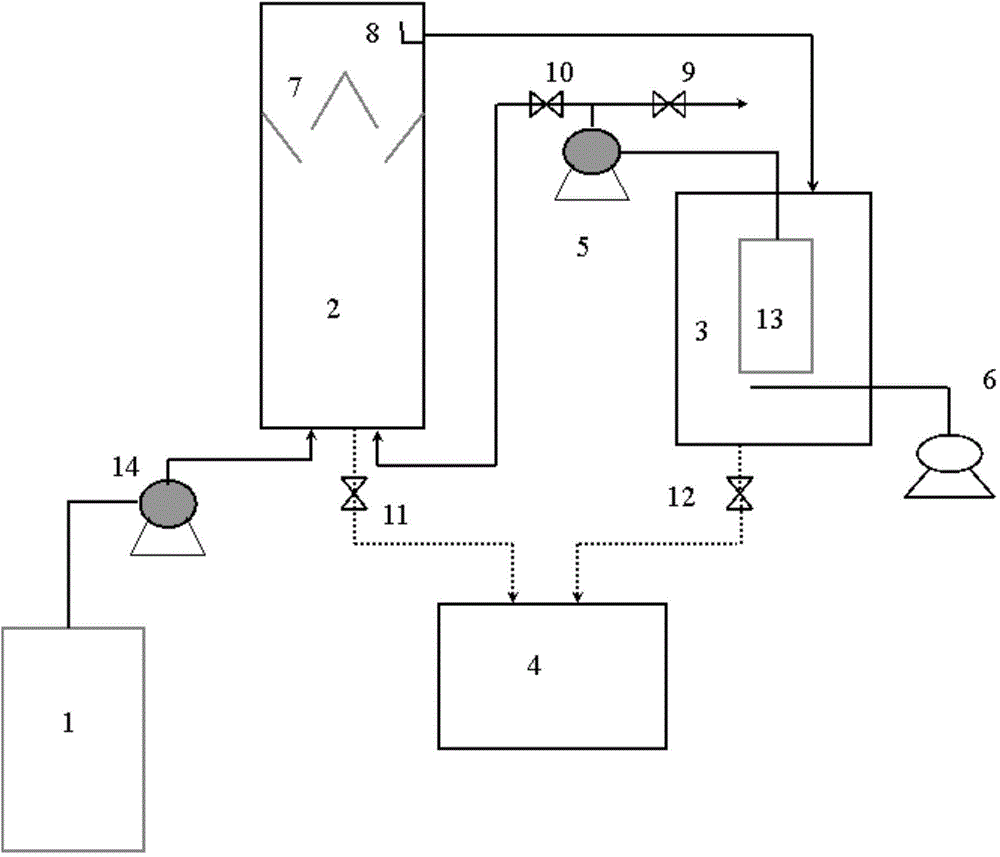

[0019] The present invention strengthens the mud-water separation anaerobic / anoxic-membrane bioreactor denitrification and dephosphorization process to treat sewage, and adopts a regulating tank (1), anaerobic / anoxic reactor (2), aerobic membrane bioreactor (3), sewage Mud thickening tank (4). A three-phase separator (7) is installed in the anaerobic / anoxic reactor (2) for mud-water separation, and a membrane module (13) is built in the good membrane bioreactor (3) for the circulation of nitrifying liquid and the system membrane The water is filtered; in the aerobic membrane bioreactor, the blower (6) is aerated to wash the membrane surface to control the membrane pollution, and the aeration also plays the role of oxygen supply to the microorganisms. The sludge discharge is regulated by opening and closing the sludge discharge valve (11) of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com