Ceramic material for false tooth preparation and preparation method thereof

A technology of ceramic materials and dentures, which is applied in the field of ceramic materials and its preparation, can solve problems such as nickel-chromium allergies, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

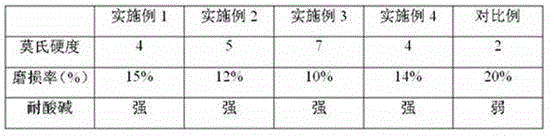

Examples

Embodiment 1

[0020] A ceramic material for denture preparation, comprising the following raw materials in parts by weight: 20 parts of 600-mesh rape straw powder, 4 parts of yttrium oxide, 0.1 part of aluminum oxide, 4 parts of zirconia, 12 parts of 800-mesh ceramic powder, 0.5 parts of polyvinyl alcohol aqueous solution.

[0021] The above-mentioned preparation method of the ceramic material used for denture preparation comprises the following steps:

[0022] Step 1, take straw powder, yttrium oxide, aluminum oxide, zirconia, ceramic powder, and polyvinyl alcohol aqueous solution in parts by weight, and put yttrium oxide, aluminum oxide, zirconia, and ceramic powder into a ball mill and grind for 2 hours to obtain the first mixture;

[0023] Step 2, put the first mixture into the crucible, heat it to 1800°C and keep it warm for 1 hour, add straw powder, then add polyvinyl alcohol aqueous solution, and stir the second mixture at 200rpm;

[0024] Step 3: Pour the second mixture into the m...

Embodiment 2

[0026] A ceramic material for denture preparation, comprising the following raw materials in parts by weight: 36 parts of 600 wheat straw powder, 5 parts of yttrium oxide, 0.2 parts of aluminum oxide, 5 parts of zirconia, 18 parts of 800 mesh ceramic powder, poly 0.8 parts of vinyl alcohol aqueous solution.

[0027] The above-mentioned preparation method of the ceramic material used for denture preparation comprises the following steps:

[0028] Step 1, take straw powder, yttrium oxide, aluminum oxide, zirconia, ceramic powder, and polyvinyl alcohol aqueous solution in parts by weight, and put yttrium oxide, aluminum oxide, zirconia, and ceramic powder into a ball mill and grind for 3 hours to obtain the first mixture;

[0029] Step 2, put the first mixture into the crucible, heat it to 2000°C and keep it warm for 1.5 hours, add straw powder, then add polyvinyl alcohol aqueous solution, and stir the second mixture at 280rpm;

[0030] Step 3: Pour the second mixture into the ...

Embodiment 3

[0032] A ceramic material for denture preparation, comprising the following raw materials in parts by weight: 38 parts of 700-mesh rape straw powder, 7 parts of yttrium oxide, 0.4 parts of aluminum oxide, 7 parts of zirconia, 20 parts of 800-mesh ceramic powder, 1.0 parts of polyvinyl alcohol aqueous solution.

[0033] The above-mentioned preparation method of the ceramic material used for denture preparation comprises the following steps:

[0034] Step 1, take straw powder, yttrium oxide, aluminum oxide, zirconia, ceramic powder, and polyvinyl alcohol aqueous solution in parts by weight, and put yttrium oxide, aluminum oxide, zirconia, and ceramic powder into a ball mill and grind for 4 hours to obtain the first mixture;

[0035] Step 2, put the first mixture into the crucible, heat it to 2200°C and keep it warm for 2 hours, add straw powder, then add polyvinyl alcohol aqueous solution, and stir the second mixture at 300rpm;

[0036] Step 3: Pour the second mixture into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com