Preparation method of high-solid-content emulsified SBS (styrene-butadiene-styrene) modified asphalt and application of modified asphalt in micro-surfacing

A technology of modified asphalt and solid content, applied in building components, building insulation materials, buildings, etc., can solve the problems of high temperature performance of the mixture, the impact of wear resistance, increased transportation costs, and slow early strength of the mixture, etc., to achieve solid The effects of high content, low production and transportation costs, and fast strength growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

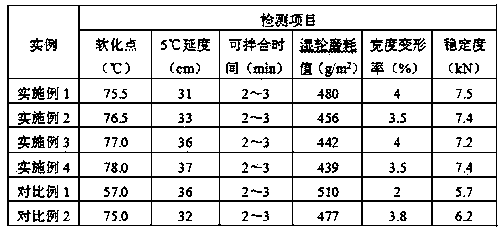

Examples

Embodiment 1

[0023] Preparation of emulsified SBS modified asphalt:

[0024] The asphalt containing 4.0% SBS modifier is heated to 160-180°C, the slow-cracking and fast-setting emulsifier is mixed with water to form a soap solution, and the temperature is adjusted to 45-65°C, according to 80 parts of asphalt and 20 parts of soap (KZW-801 2.7 parts of emulsifier, 17.3 parts of water, adding acid to adjust the pH value of the soap liquid to 2.0) at the same time into the colloid mill, high-speed grinding and shearing, cooling down to below 80 ° C through the heat exchanger, and the solid content of 80 can be produced. % high concentration modified emulsified asphalt products.

[0025] The preparation method of emulsified modified asphalt micro-surface, comprises the following steps:

[0026] 1) Take 100kg of stone meeting the MS-3 type gradation, add 2kg of 42.5 cement to the stone and mix evenly, then add 11.5kg of water for pre-mixing;

[0027] 2) Add 8.8kg of emulsified SBS modified asp...

Embodiment 2

[0030] Preparation of emulsified SBS modified asphalt:

[0031] The asphalt containing 4.5% SBS modifier is heated to 160-180°C, the slow-cracking and fast-setting emulsifier is mixed with water to form a soap solution, and the temperature is adjusted to 45-65°C, according to 76 parts of asphalt and 24 parts of soap (HSRH emulsifier 2.5 parts, water 21.5 parts, add acid to adjust the pH value of the soap liquid to 2.0) at the same time into the colloid mill, high-speed grinding and shearing, after the heat exchanger cools down to below 80°C, the solid content of 76% can be produced High concentration modified emulsified asphalt product.

[0032] The preparation method of emulsified modified asphalt micro-surface, comprises the following steps:

[0033] 1) Take 100kg of stone meeting the MS-3 type gradation, add 2kg of 42.5 cement to the stone and mix evenly, then add 11.0kg of water for pre-mixing;

[0034] 2) Add 9.2kg of emulsified SBS modified asphalt with a solid content...

Embodiment 3

[0037] Preparation of emulsified SBS modified asphalt:

[0038] The asphalt containing 5.0% SBS modifier is heated to 160-180°C, the slow-cracking and fast-setting emulsifier is mixed with water to form a soap solution, and the temperature is adjusted to 45-65°C, according to 73 parts of asphalt and 27 parts of soap (CMK-30 2.4 parts of emulsifier, 24.6 parts of water, adding acid to adjust the pH value of the soap liquid to 2.0) at the same time into the colloid mill, high-speed grinding and shearing, cooling down to below 80 °C through the heat exchanger, and the solid content of 73 can be produced. % high concentration modified emulsified asphalt products.

[0039] The preparation method of emulsified modified asphalt micro-surface, comprises the following steps:

[0040] 1) Take 100kg of stone meeting the MS-3 type gradation, add 2kg of 42.5 cement to the stone and mix evenly, then add 11.0kg of water for pre-mixing;

[0041] 2) Add 9.3kg of emulsified SBS modified aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com