A method of using magnetic field to strengthen the direct reduction of carbon pellets in iron-containing powder

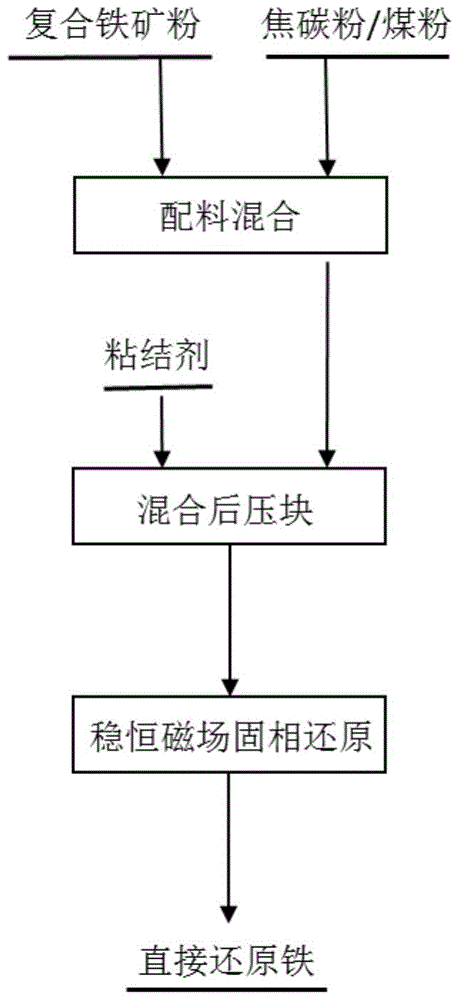

A technology with carbon pellets and magnetic field strengthening, applied in the field of iron and steel metallurgy, can solve the problems of long reduction time, high reduction temperature, low metallization rate, etc., and achieve the effect of improving production efficiency, overcoming high reduction temperature and shortening reduction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

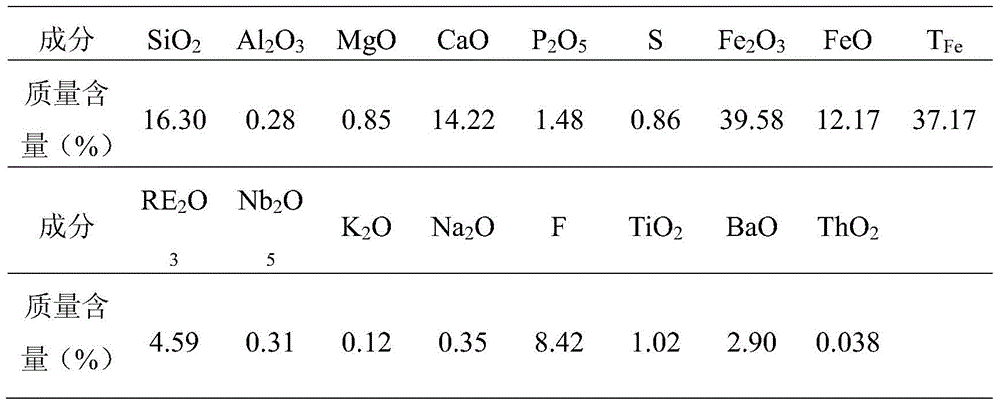

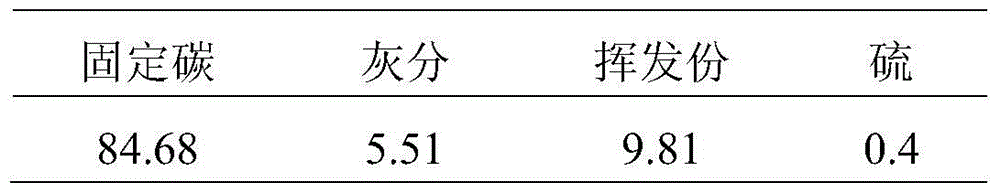

[0036] (1) Raw material ratio: According to the above composition table, Baiyan Obo iron ore powder is mixed with coke powder and fully mixed. The atomic ratio of fixed carbon in coke powder to iron oxide oxygen in iron ore powder is C / O is 1.2. After mixing evenly, a binder is added, the binder is water glass, and the addition amount is 5% of the total mass of raw materials.

[0037] (2) Preparation of pellets: the mixture is pressed into carbon-containing pellets with a diameter of 10-12 mm. The carbon-containing pellets are dried and used for later use. The drying method is to keep the temperature at 105° C. for 12 hours.

[0038] (3) Solid-phase reduction: spread two layers of carbon-containing pellets on a tray, place them in a magnetic field tubular reduction furnace for reduction, the reduction temperature is 950°C; the magnetic field strength is 0.97T; the reduction time is 40 min.

[0039] After the slag and iron are separated, a direct reduced iron product with a ...

Embodiment 2

[0041] (1) Raw material ratio: According to the above composition table, Baiyan Obo iron ore powder is mixed with coke powder and fully mixed. The atomic ratio of fixed carbon in coke powder to iron oxide oxygen in iron ore powder is C / O is 1.2. After mixing evenly, a binder is added, the binder is water glass, and the addition amount is 5% of the total mass of raw materials.

[0042] (2) Preparation of pellets: the mixture is pressed into carbon-containing pellets with a diameter of 10-12 mm. The carbon-containing pellets are dried and used for later use. The drying method is to keep the temperature at 105° C. for 12 hours.

[0043] (3) Reduction parameters: spread two layers of carbon-containing pellets on a tray, and place them in a tube-type reduction furnace without a magnetic field for reduction. The reduction temperature is 950° C. and the reduction time is 40 minutes.

[0044] After the slag and iron are separated, a direct reduced iron product with a metallization ...

Embodiment 3

[0046] (1) Raw material ratio: According to the above composition table, Baiyan Obo iron ore powder is mixed with coke powder and fully mixed. The atomic ratio of fixed carbon in coke powder to iron oxide oxygen in iron ore powder is C / O is 1.2. After mixing evenly, a binder is added, the binder is water glass, and the addition amount is 5% of the total mass of raw materials.

[0047](2) Preparation of pellets: the mixture is pressed into carbon-containing pellets with a diameter of 10-12 mm. The carbon-containing pellets are dried and used for later use. The drying method is to keep the temperature at 105° C. for 12 hours.

[0048] (3) Reduction parameters: Spread 2 layers of carbon-containing pellets on a tray, place them in a magnetic field tubular reduction furnace for reduction, the reduction temperature is 950°C; the magnetic field strength is 0.4T; the reduction time is 40 min.

[0049] After the slag and iron are separated, a direct reduced iron product with a metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com