A kind of automatic production equipment of two-component white cotton

An automatic production, two-component technology, applied in non-woven fabrics, textiles and papermaking, melt spinning, etc., can solve the problems of PET rolls and semi-products occupying a large area of space, high production costs, and labor intensity of workers. , to reduce the labor intensity of workers, reduce production energy consumption, and avoid high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

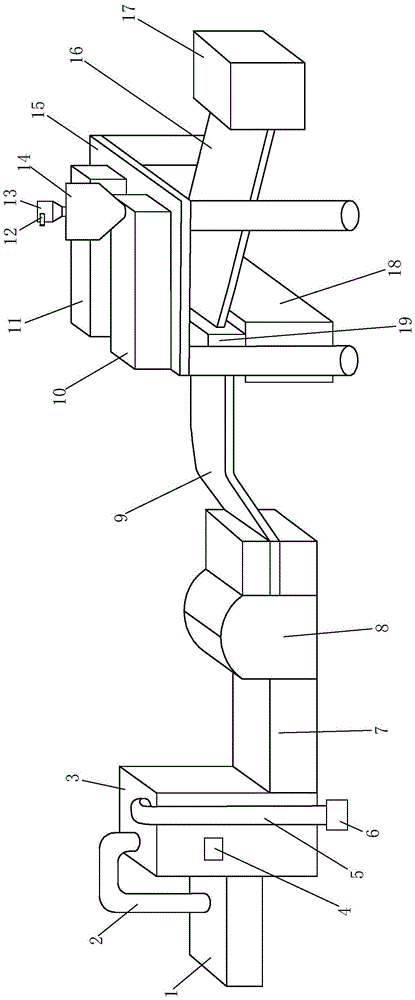

[0013] Such as figure 1 As shown, the automatic production equipment for two-component white cotton of the present invention includes an opener 3, a carding machine 8, an extruder 10, a melt blown machine 19, and a reel 17, and the opener 3 is provided with a feed Device 1, the feeding device 1 is connected to the opener 3 through the feeding pipe 2, the front end of the feeding pipe 2 is connected to the feeding device 1, and the rear end of the feeding pipe 2 is penetrated into the opener 3 from the top wall of the opener 3 In the inner cavity, there is a fan 6 on the side of the opener 3. The air outlet of the fan 6 is connected to the inner cavity of the opener 3 from the top wall of the opener 3 through a duct 5, and the PET fiber enters and opens through the feed pipe 2. The loosening machine 3 is immediately blown away by the wind of the air pipe 5, and the opening effect is very good. On the two opposite side walls of the opener 3, a booster device 4 that can increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com