A Design Method for Cement Stabilized Recycled Aggregate Base or Subbase

A technology of recycled aggregate and cement stabilization, which can be applied to coagulable pavements, roads, roads and other directions paved on site, and can solve problems such as failure to achieve fatigue cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

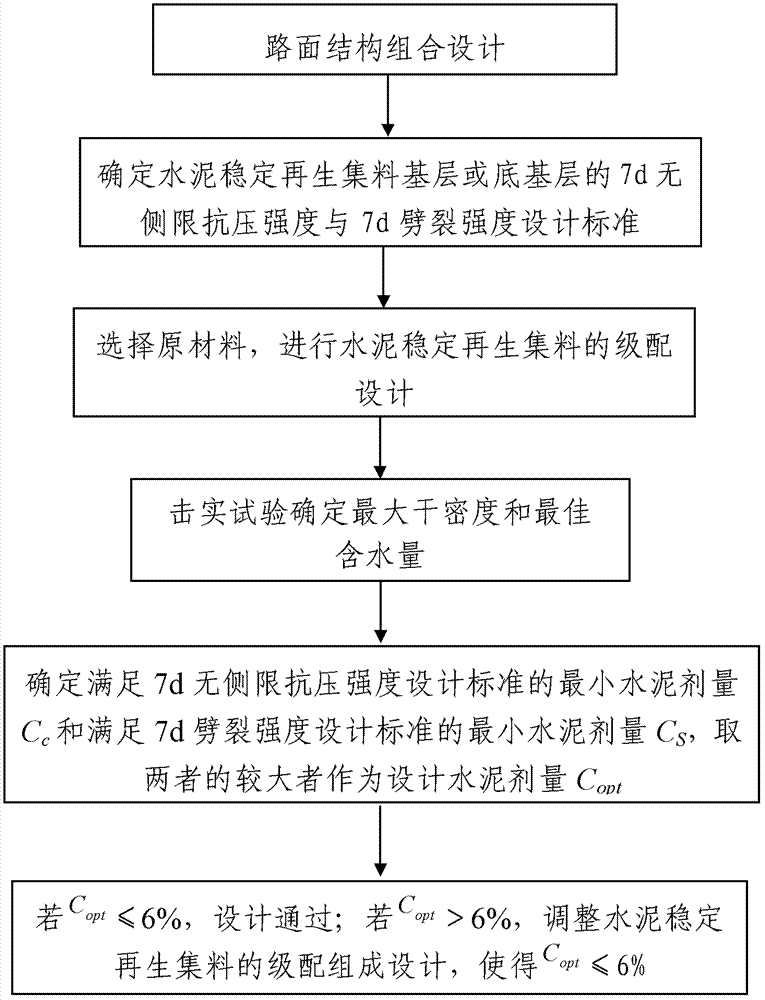

[0073] A design method for cement-stabilized recycled aggregate subbase, the method flow is referred to figure 1 , the specific steps are as follows.

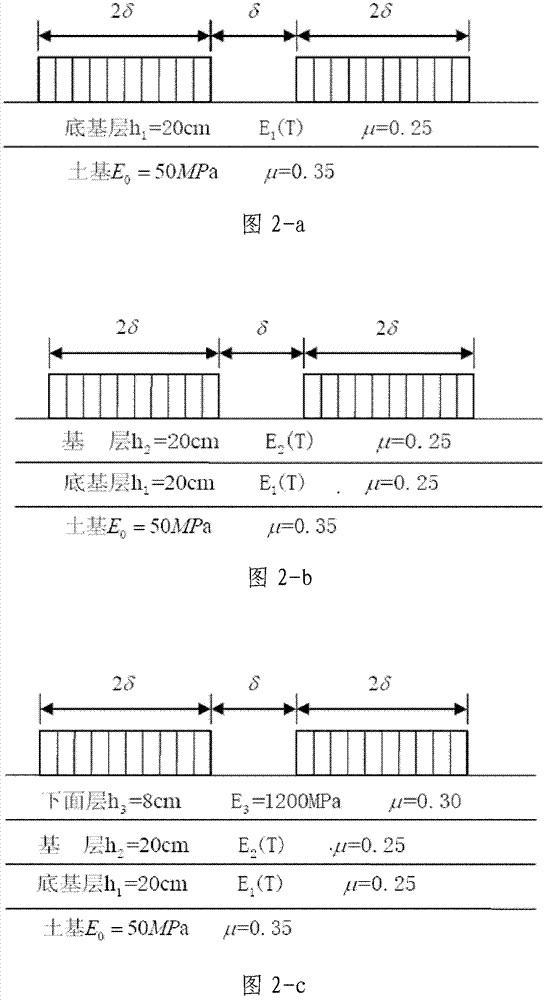

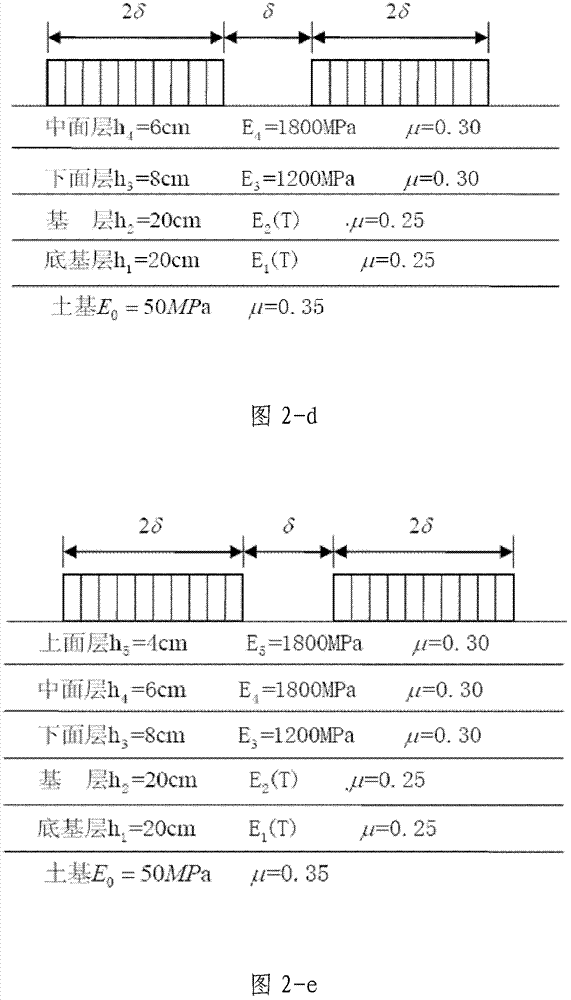

[0074] Step 1: Determine the thickness of the pavement structure combination and the cement-stabilized recycled aggregate subbase.

[0075] (1) Traffic Analysis

[0076] Table 1 shows the average daily traffic volume and vehicle types of a newly-built expressway in the first year of its opening (2013).

[0077] Table 1 Traffic volume and vehicle composition in the first year of operation

[0078]

[0079]The combined design of the pavement structure takes the standard axle load (BZZ-100) of 100kN on the single axle of the double wheel set, and converts various axle loads into standard axle loads. The axle load conversion results of deflection and semi-rigid base layer tensile stress are as follows: Table 2 and Table 3 are shown.

[0080] Table 2 Axle load conversion result table (deflection)

[0081]

[0082]

[0...

Embodiment 2

[0141] Another design method for cement-stabilized recycled aggregate subbase, the method flow refers to figure 1 , the specific steps are as follows.

[0142] Step 1: Determining the combination of pavement structure and the thickness of cement-stabilized recycled aggregate base.

[0143] (1) Traffic analysis

[0144] Table 12 shows the average daily traffic volume and vehicle types in the first year (2013) of a newly-built secondary highway design.

[0145] Table 12 Traffic Volume and Vehicle Composition in 2013

[0146]

[0147]

[0148] The combination design of the pavement structure takes the standard axle load of 100kN on the single axle of the double-wheel set (BZZ-100), and converts various axle loads into standard axle loads. The results are shown in Table 13 and Table 14:

[0149] Table 13 Axle load conversion result table (deflection)

[0150]

[0151] Table 14 Axle load conversion results (semi-rigid base layer bottom tensile stress)

[0152]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com