Water-saving container plating roof

A water-saving, container technology, which is applied in the direction of roofing, container cultivation, roof covering, etc., can solve the problems of difficulty in transportation and handling to the roof, increase the manufacturing cost of planting boxes, increase the manufacturing cost, etc., and achieve good water supply performance. , the structure is simple, the effect of simplifying the installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

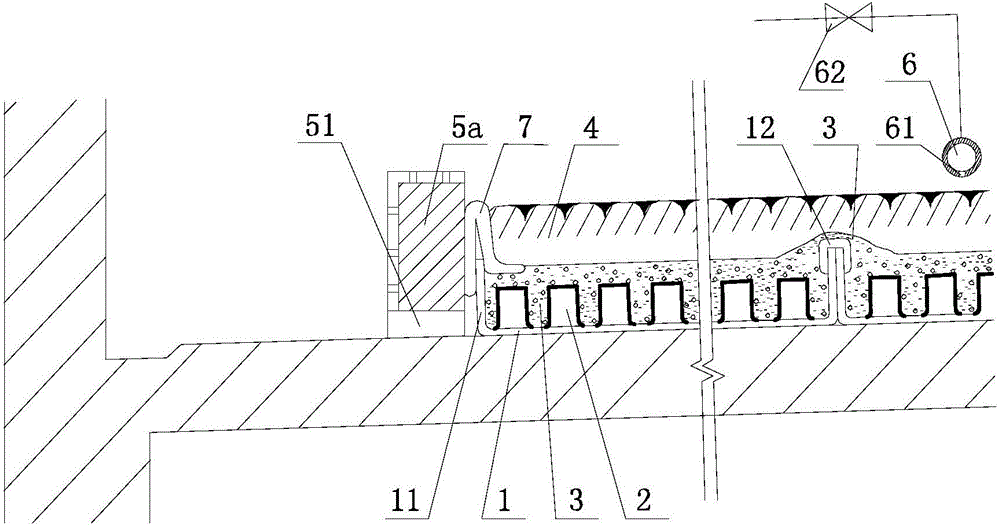

[0033] Example 1, such as figure 1 and figure 2 as shown in:

[0034] In the present embodiment, the present invention includes a pool ridge 5a arranged on the building roof 13, in which several shallow pans 1 closely arranged in a matrix are arranged, and the pool ridge 5a and the matrix arrangement The shallow plate 1 constitutes a planting pond; a cylindrical cup plate 2 is arranged in the shallow plate 1, and the described cylindrical cup plate 2 is composed of a plurality of independent cylindrical cups, and the mouth of the cylindrical cup The edges are connected together and arranged in a matrix; the mouth of the cylindrical cup plate 2 is downward, that is, the cylindrical cup plate 2 is buckled in the shallow plate 1; the gap 23 between the independent cylindrical cups A water-absorbing filter material 3 is provided in the middle, and a waterproof adhesive tape 12 for bonding the two side walls is arranged on the upper part of the side walls of the two adjacent sha...

Embodiment 2

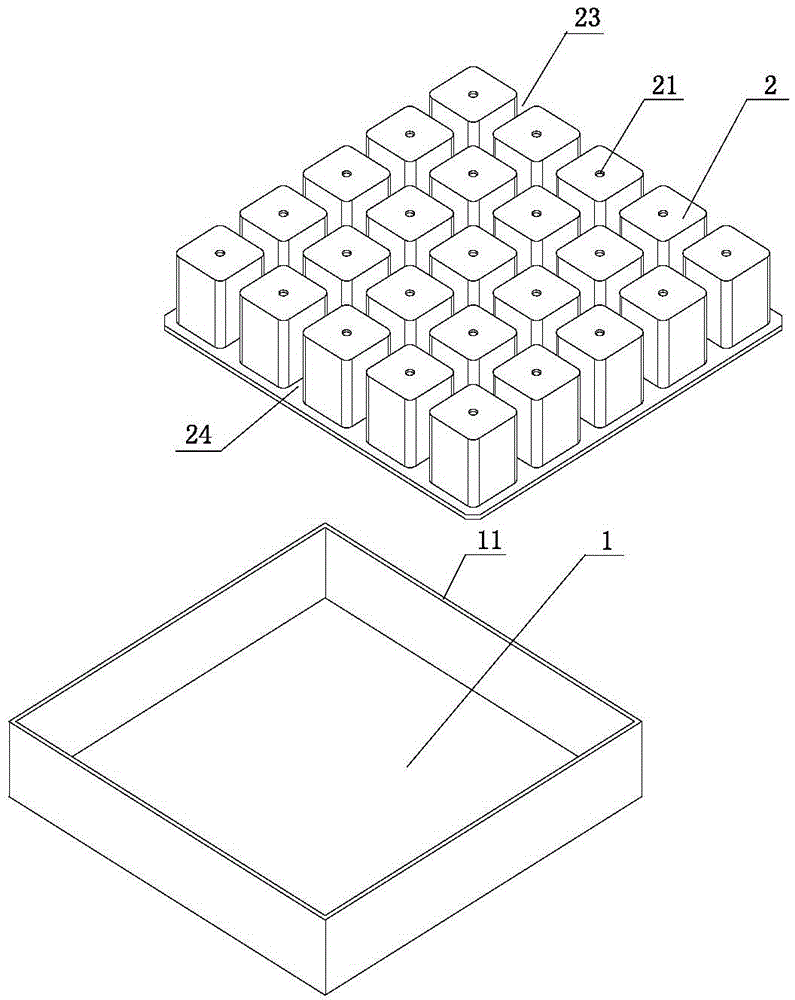

[0054] Example 2, such as image 3 and Figure 4 as shown in:

[0055] In this embodiment, the mouth of the cylindrical cup plate 2 faces upwards, that is, the cylindrical cup plate 2 is buckled upside down in the platter 1 .

[0056] In this embodiment, each cup bottom of the cylindrical cup plate 2 is provided with a first through hole 21, which is actually a water hole; the center of the edge 24 of the cup is provided with a second through hole 22, which is actually a water hole. is the vent.

[0057] In specific use, if the water-absorbing filter material in the shallow pan adopts air-entrained concrete particles, its water storage rate can reach 50%. In this embodiment, the space between the cylindrical cups is the water storage space. In order to obtain a larger water storage space, the cup body of the cylindrical cup can be appropriately reduced, so that the gap between the cylindrical cups is relatively enlarged. Fill the water-absorbing filter material in the cyl...

Embodiment 3

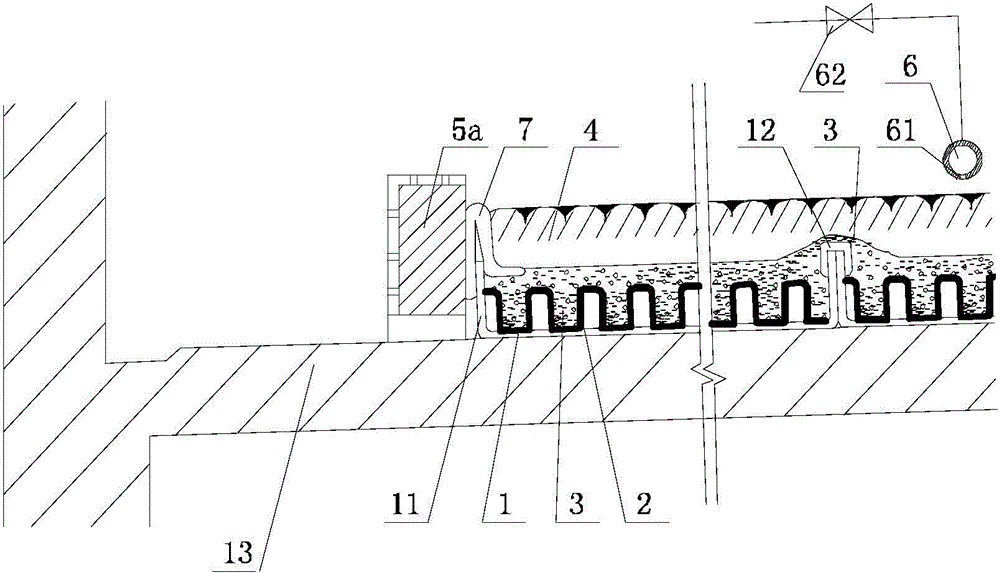

[0059] Example 3, such as Figure 5 as shown in:

[0060] For small building roofs that require greening, anti-corrosion wood or aluminum profiles can be used to make a frame 5b to replace the pool ridge. The height of the frame 5b should be about 80mm higher than the shallow plate 1, and the frame is placed on the shallow plate array. On the periphery, the method of tensioning the steel rope is used to prevent its deformation, and the bottom is not fixed and there is no need to specially reserve a drain hole. Polyester filter cotton 7 should be arranged between or between the enclosure and the shallow pan. The polyester filter cotton 7 should have a certain width, which can fully cover the planting soil and prevent the planting soil from falling into the gap between the enclosure and the shallow pan.

[0061] In this embodiment, flagstone paths 52 and crushed stones 53 can be laid on the original roof outside the pool ridge.

[0062] Other parts of this embodiment are exact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com