Pneumatic centrifugal clutch and manufacturing method thereof

A centrifugal clutch and centrifugal body technology, applied in automatic clutches, mechanical drive clutches, clutches, etc., can solve the problems of poor transmission effect, high engine temperature, easy leakage, etc. stop smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

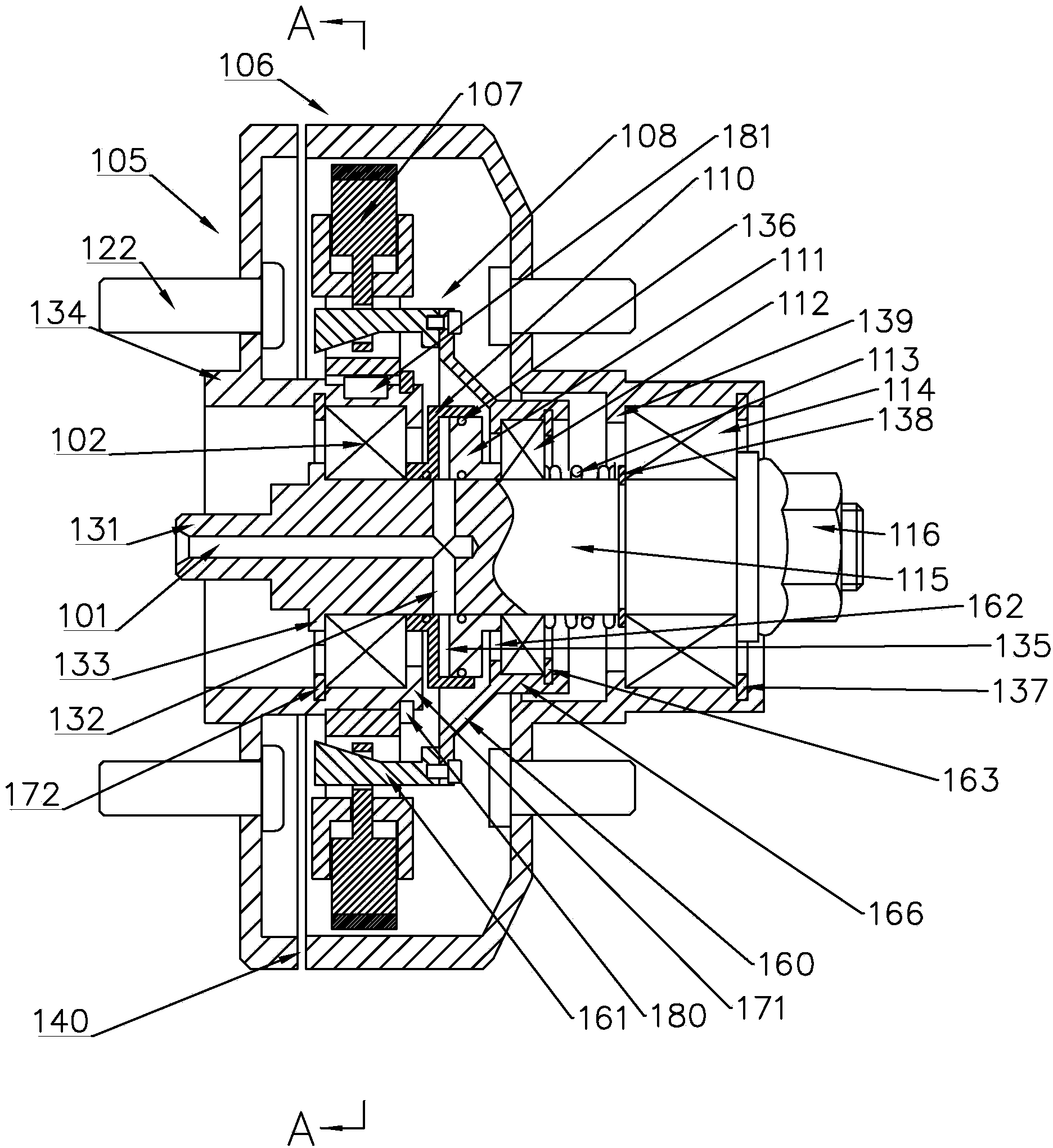

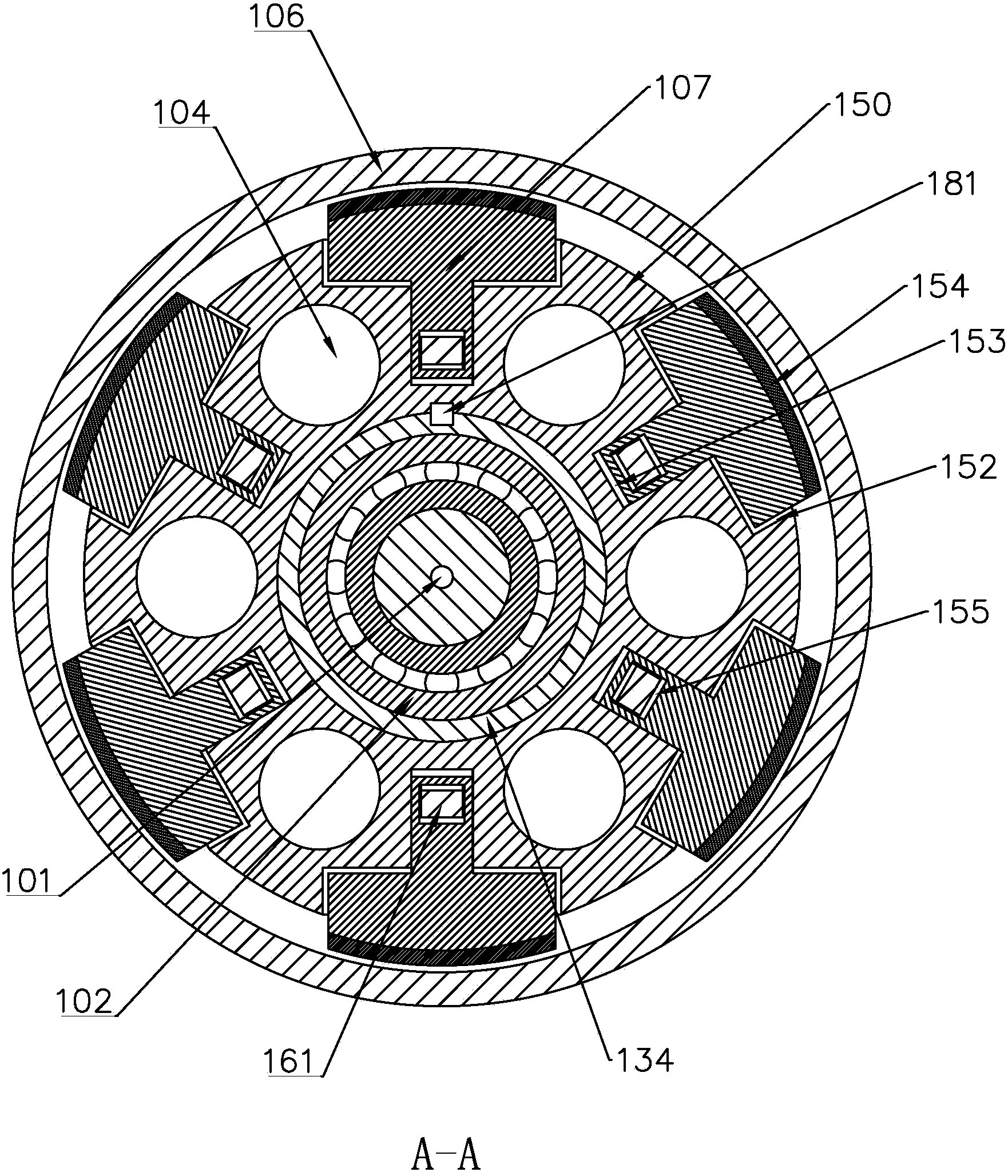

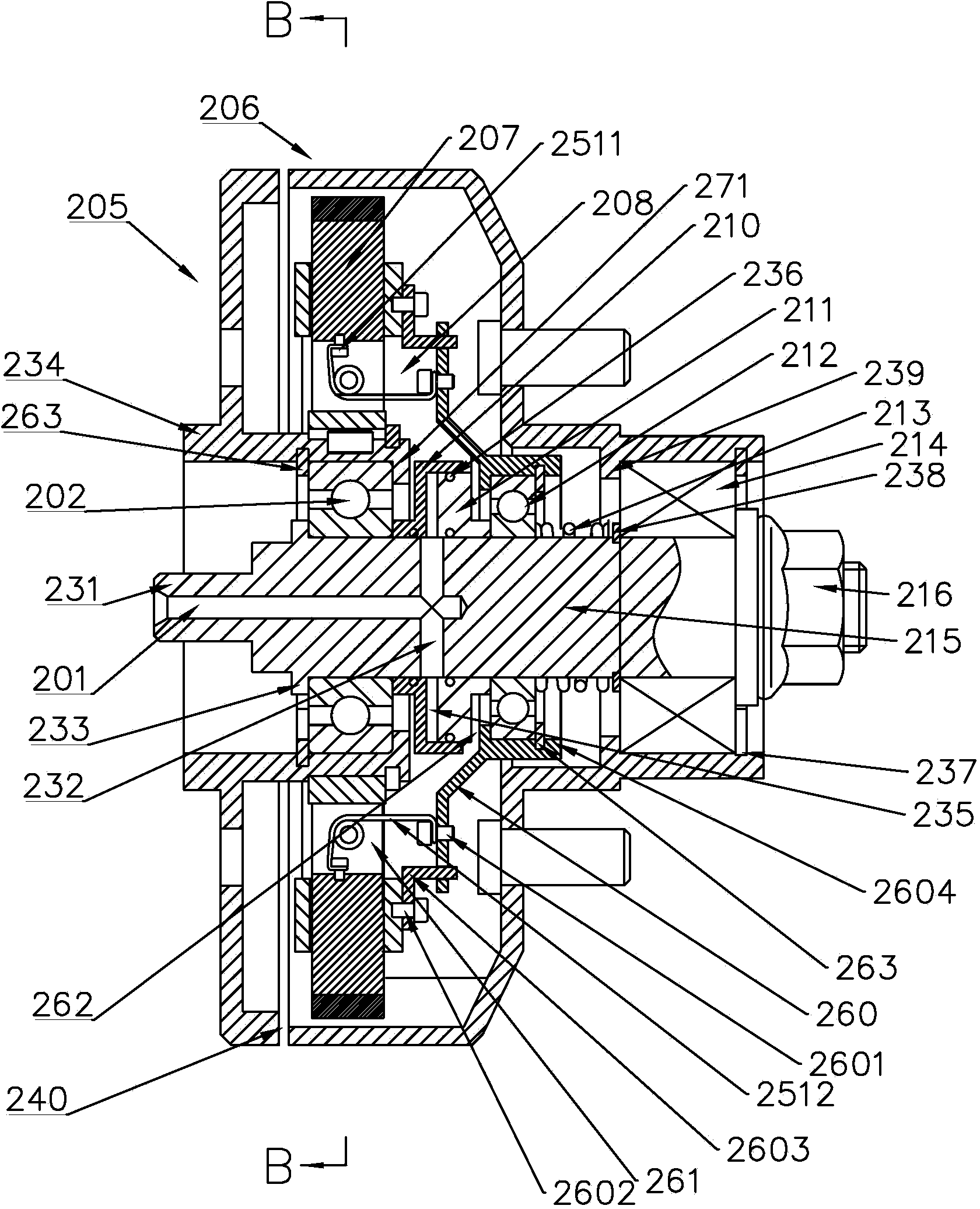

[0039] The first embodiment of the pneumatic centrifugal clutch of the present invention.

[0040] see figure 1 , figure 2 , which shows a first embodiment of the electromagnet core arrangement of the present invention.

[0041] Such as Figure 1 As shown, the first embodiment of the present invention includes a main shaft 115, a driving part bearing 102, a driving part 105, a centrifugal body 107, a driven part 106, a circular cylinder 110, a piston 111, a thrust bearing 112, a return spring 113, a driven part Bearing 114, centrifugal body pulling mechanism 108. One end of the main shaft 115 forms a vent nozzle 131, and an air guide hole 101 is provided along the direction of the central axis from one end of the vent nozzle 131 of the main shaft 115. match. At the position near the blind end of the air guide hole 101 , six radial air guide holes 132 are opened in the radial direction, so as to guide the driving gas into the circular cylinder 110 . At the end of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com