High-voltage electric field aided cooling and dehumidifying device

A high-voltage electric field and auxiliary cooling technology, which is used in the fields of air dehumidification, high-voltage electric field auxiliary cooling and dehumidification, and independent heat and humidity treatment, can solve the problems of increasing energy consumption of air conditioning systems, and achieve the effects of reducing energy consumption, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

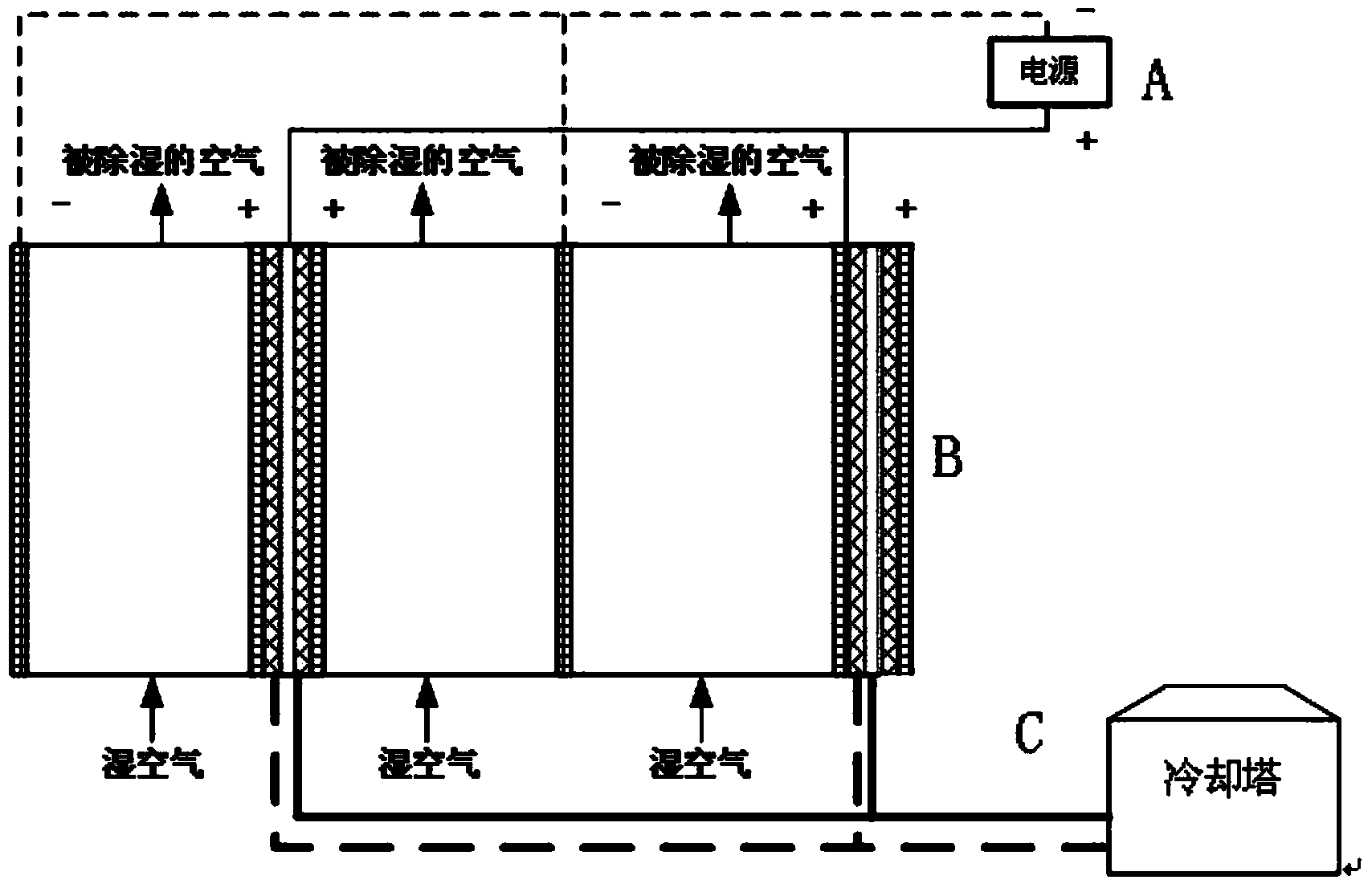

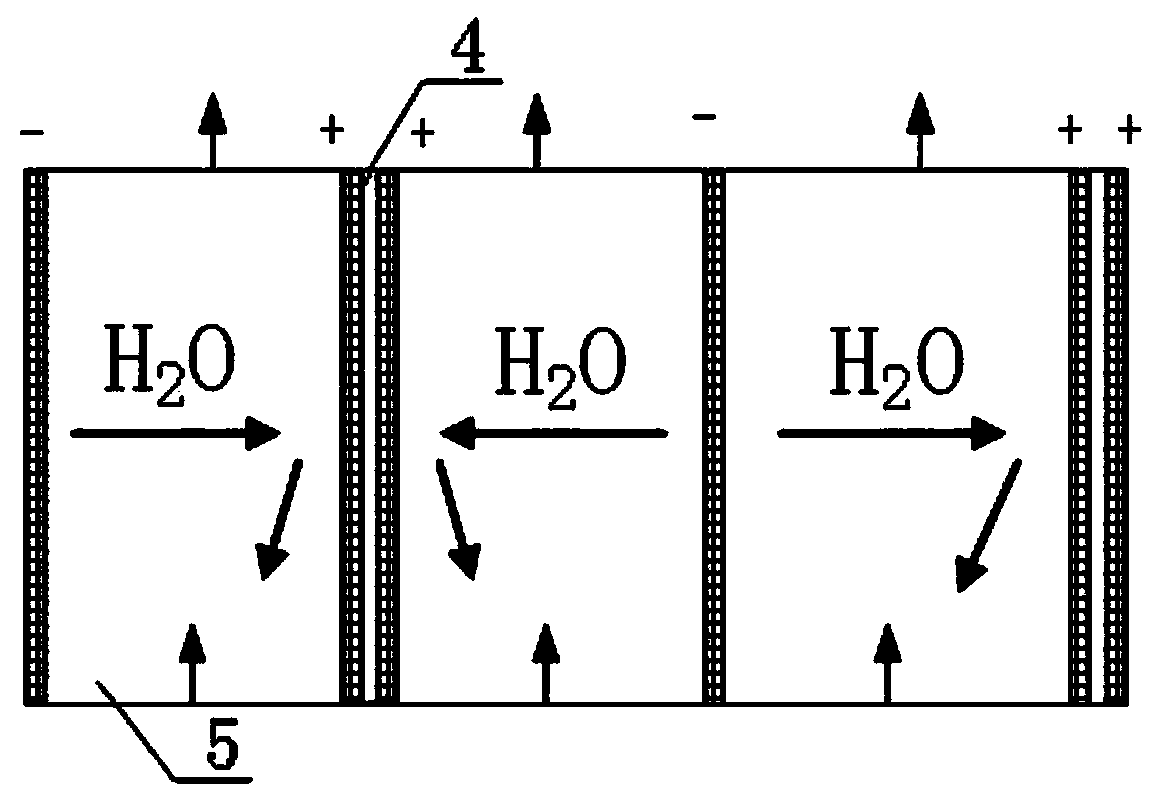

[0019] as attached figure 1 and 2 As shown, a high-voltage electric field assisted cooling and dehumidification device includes a DC power supply unit A, a dehumidification unit B and a cooling unit C. The dehumidification unit B is composed of several dehumidification chambers 5, and each dehumidification chamber 5 is composed of positive and negative electrodes The plates are relatively parallel and vertically arranged to form an air flow channel. The polarity of the electrode plates of adjacent dehumidification chambers 5 is the same, and a cooling water layer 4 is arranged between adjacent positive electrode plates. In each dehumidification chamber 5 in the present invention, adjacent negative The electrode plate adopts a common negative electrode plate.

[0020] The DC power supply unit A is respectively connected to the positive and negative electrode plates of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com