gis equipment irregular flange sf 6 Air tightness testing device and method

A technology of air tightness detection and test equipment, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of low safety factor and reliability, complicated and time-consuming partial bandaging, etc., to improve personal safety factor, The effect of rich and diverse products and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

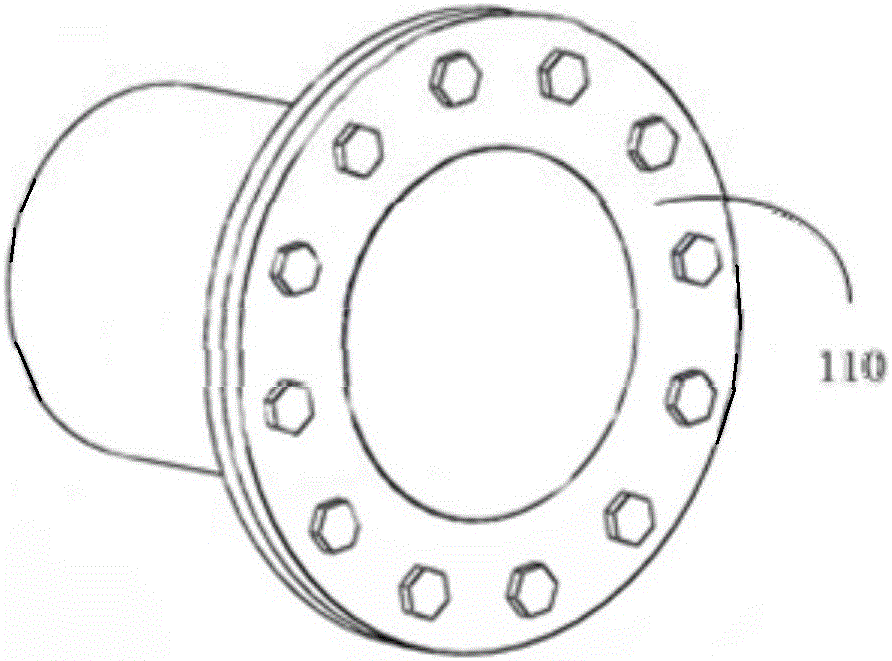

[0038] Such as Figure 1 to Figure 3 As shown, this embodiment proposes a GIS equipment terminal flange SF 6 The air tightness detection test device includes the GIS equipment terminal flange 110, the terminal flange film cover 120 covered on the GIS equipment terminal flange 110, and makes the terminal flange film cover 120 and the GIS equipment terminal flange 110 Keep a 5mm gap, and keep a certain gap between the two to facilitate the formation of a gas storage chamber to collect SF leaked from the GIS equipment terminal flange 6 gas. In addition, the terminal flange film cover 120 is made of industrially produced single-layer linear low-density polyethylene film material, which is low in cost, designed for one-time use, simple and convenient, and highly scalable.

[0039] The terminal flange film cover 120 includes a cylindrical terminal flange film body, and an open end 122 and a closed end 124 respectively arranged on two sides of the terminal flange film body. The te...

Embodiment 2

[0049] Such as Figure 4 to Figure 6 As shown, this embodiment proposes a GIS equipment transition flange SF 6 The air tightness detection test device comprises a GIS equipment transition flange 210, a transition flange membrane cover 220 covering the GIS equipment transition flange 210, and a gap between the transition flange membrane cover 220 and the GIS equipment transition flange 210. Keep a gap of 5mm, and keep a certain gap between the two to facilitate the formation of a gas storage chamber to collect the SF leaked from the transition flange 210 of the GIS equipment 6 gas. In addition, the transition flange film cover 220 is made of industrially produced single-layer linear low-density polyethylene film material, which is low in cost, designed for one-time use, simple and convenient, and highly scalable.

[0050] Furthermore, the GIS equipment transition flange 210 includes a transition flange first portion 212 and a transition flange second portion 214 . The transi...

Embodiment 3

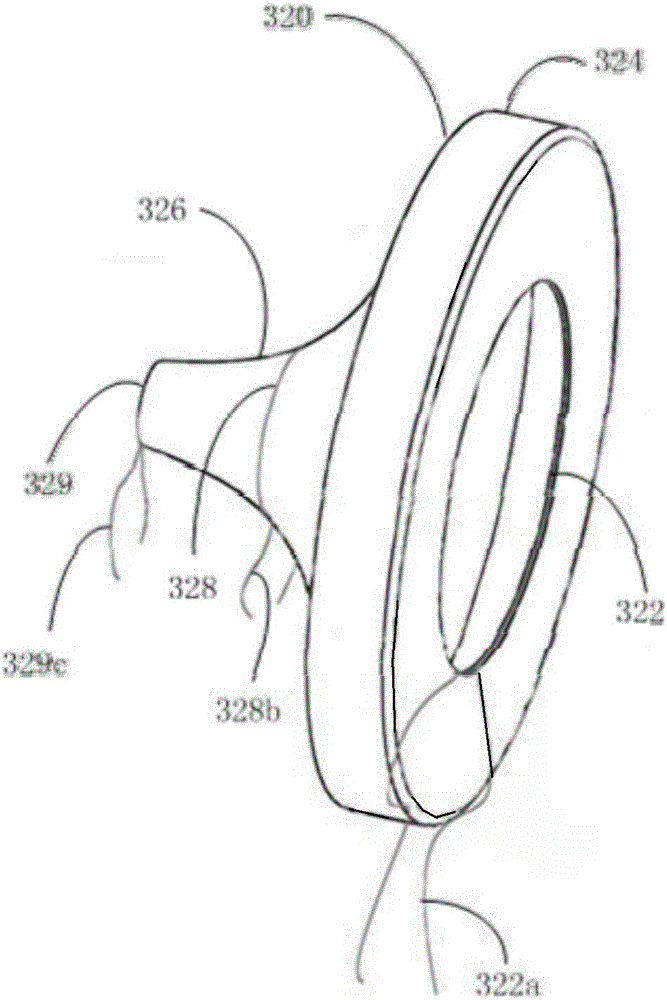

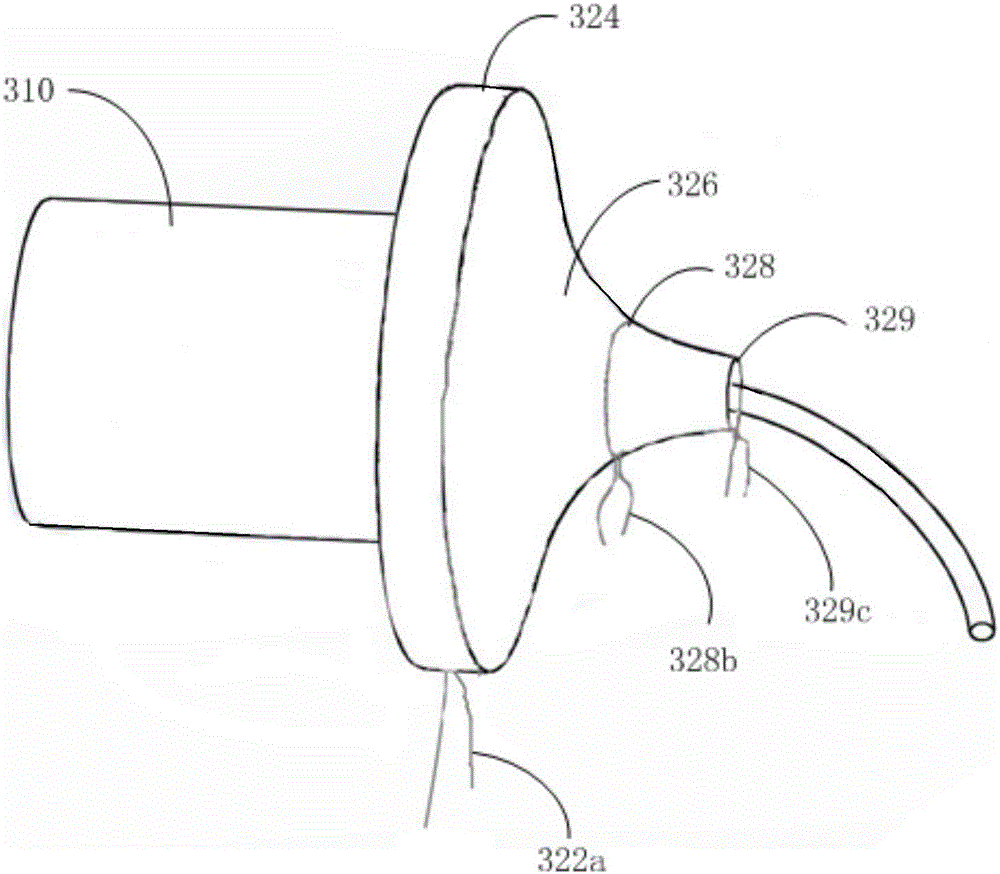

[0060] Such as Figure 7 to Figure 9 As shown, this implementation proposes a GIS equipment irregular flange SF 6 The air tightness detection test device comprises an irregular flange 310 of GIS equipment with gradually smaller diameter, an irregular flange film cover 320 covering the irregular flange 310 of GIS equipment, and making the irregular flange film cover Keep a 5mm gap between 320 and the irregular flange 310 of the GIS equipment, and keep a certain gap between the two to facilitate the formation of a gas storage chamber to collect the SF leaked from the irregular flange 310 of the GIS equipment 6 gas. In addition, the irregular flange film cover 320 is made of industrially produced single-layer linear low-density polyethylene film material, which is low in cost, designed for one-time use, simple and convenient, and highly scalable. In addition, the irregular flange 310 of the GIS equipment can also be set such that the diameter gradually increases from small to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com