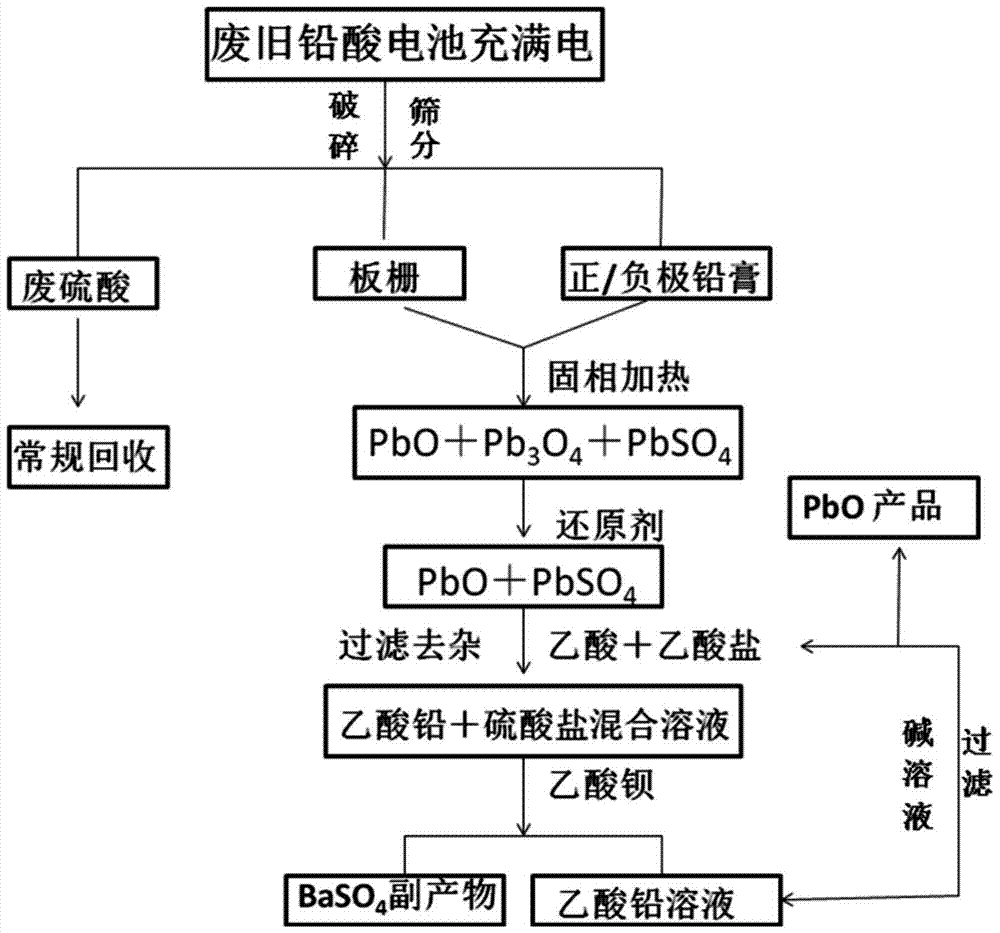

A method for directly wet-preparing PBO from waste lead-acid batteries

A lead-acid battery, lead-acid battery technology, applied in the directions of lead monoxide, battery recycling, lead oxide, etc., can solve the problems of fewer steps, lead recovery efficiency, raw material consumption, and many steps, so as to reduce raw material and energy consumption, step Few, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Charge the used lead-acid battery at 2.45V / full charge for 5 hours at a current limit of 0.02C at room temperature, so that most of the active material in the negative electrode plate of the battery is converted to lead Pb, the active material in the positive electrode plate Mostly converted to PbO 2 Use mechanical dismantling methods to separate and sort the above-mentioned fully charged waste lead-acid batteries to obtain lead paste, grids, waste sulfuric acid, separators and shells. The separated positive / negative lead paste and waste grids are crushed and sieved with a 100-mesh stainless steel screen. The larger lead paste particles are continuously transferred to the pulverizer for crushing until all the lead paste can pass through the screen. The crushed and sieved positive / negative lead paste and lead grid powder are thoroughly mixed in solid phase.

[0036] (2) Take 1kg of the mixture of lead paste and lead grid powder, slowly raise the temperature to 150℃ unde...

Embodiment 2

[0040] (1) Charge the used lead-acid battery at 2.45V / full charge at normal temperature and limit the current to 0.02C for 6 hours, so that most of the active material in the negative electrode plate of the battery is converted to lead Pb, the active material in the positive electrode plate Mostly converted to PbO 2 ; Use mechanical disassembly or crushing and sorting methods to separate and sort the above-mentioned fully charged waste lead-acid batteries to obtain lead paste, grids, waste sulfuric acid, separators and shells. The separated positive / negative lead paste and waste grids are crushed and sieved with a 100-mesh stainless steel screen. The larger lead paste particles are continuously transferred to the pulverizer for crushing until all the lead paste can pass through the screen. The crushed and sieved positive / negative lead paste and lead grid powder are thoroughly mixed in solid phase.

[0041] (2) Take 1kg of lead paste and lead grid powder mixture, slowly raise the ...

Embodiment 3

[0045] (1) Charge the used lead-acid battery at 2.45V / full charge at normal temperature and limit the current to 0.02C for 10 hours, so that most of the active material in the negative electrode plate of the battery is converted to lead Pb, the active material in the positive electrode plate Mostly converted to PbO 2 ; Use mechanical disassembly or crushing and sorting methods to separate and sort the above-mentioned fully charged waste lead-acid batteries to obtain lead paste, grids, waste sulfuric acid, separators and shells. The separated positive / negative lead paste and waste grids are crushed and sieved with a 100-mesh stainless steel screen. The larger lead paste particles are continuously transferred to the pulverizer for crushing until all the lead paste can pass through the screen. The crushed and sieved positive / negative lead paste and lead grid powder are thoroughly mixed in solid phase.

[0046] (2) Take 1kg of lead paste and lead grid powder mixture, slowly raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com