A terminal assembly machine for mounting connectors

A connector terminal and assembly machine technology, applied in the field of connector terminal assembly machine, can solve the problems of unstable metal terminals, poor product quality, complicated production processes, etc., to improve production efficiency and production quality, prevent a large number of The effect of defective products to avoid deformation or bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order for those skilled in the art to better understand the technical solutions of the present invention, the present invention is further described below with reference to the accompanying drawings.

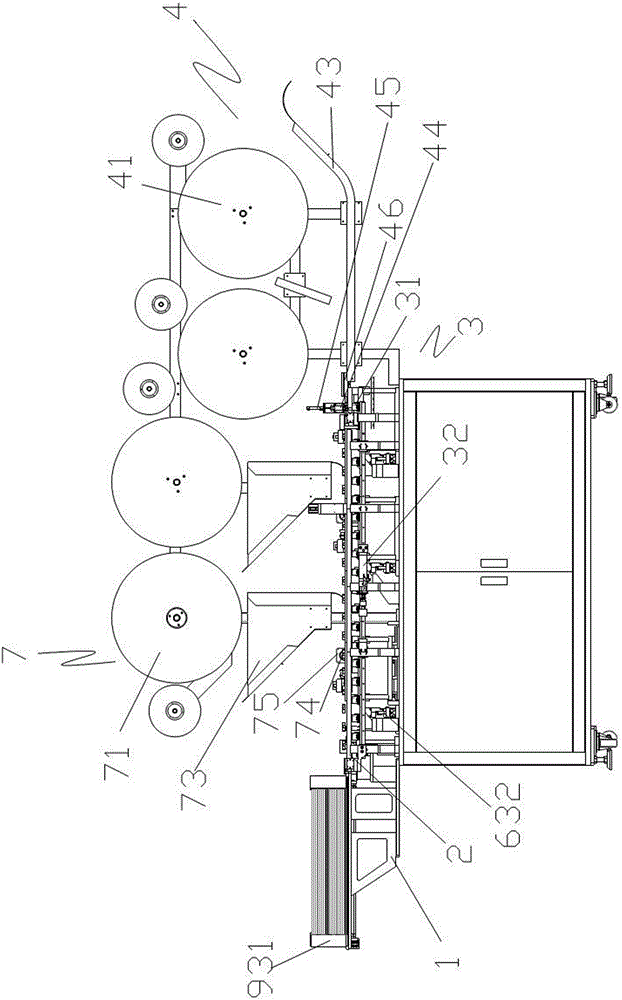

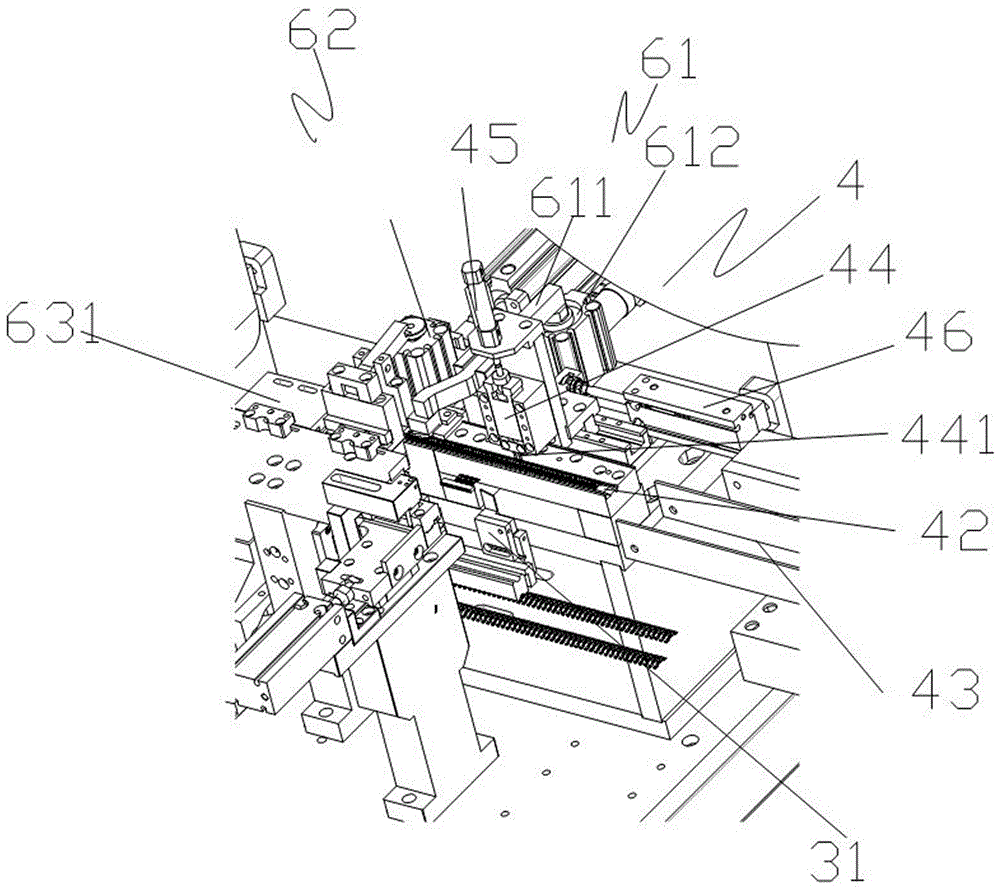

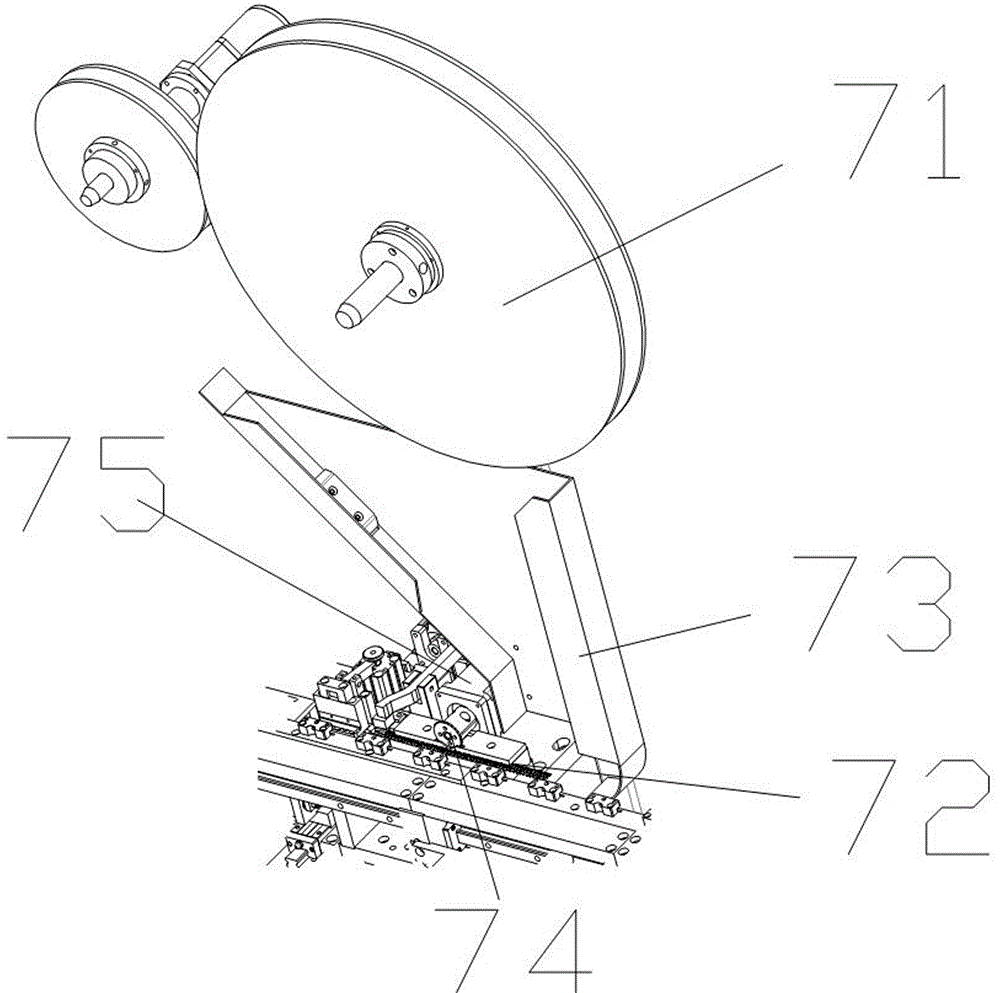

[0029] like figure 1 As shown, a connector terminal assembly machine includes a rack 1 with a bearing platform and a vibrating plate, a track 2 that is connected to the output end of the vibrating plate and is laid on the bearing platform, and the size of the track 2 is the same as that of the connector row. match the size of the mother. The front end of the track 2 communicates with the output end of the vibrating plate, and the middle position of the bottom of the track 2 is provided with a groove for moving the connector female row inside the track. A transmission mechanism 3 for moving the female row of the connector is installed and fixed below the rail 2 on the bearing platform. The bearing platform is provided with the first feeding mechanism 4, the first linka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com