Water filling type submersible motor with improved stator iron core pressing rings

A stator core and submersible motor technology, applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of complex distribution of end windings of water-filled submersible motors, waste of pressure ring materials, water friction loss, etc., and achieve saving The effect of pressing ring material, improving the integrity of force and bearing capacity, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking the motor YBQ2800 / 4-S (10000) water-filled submersible motor for mining increased safety submersible pumps as an example, the relevant parameters of the water-filled submersible motor are as follows: the outer diameter of the stator core is 850mm, the inner diameter of the stator core The length of the stator core is 1550mm, and the number of stator slots is 60.

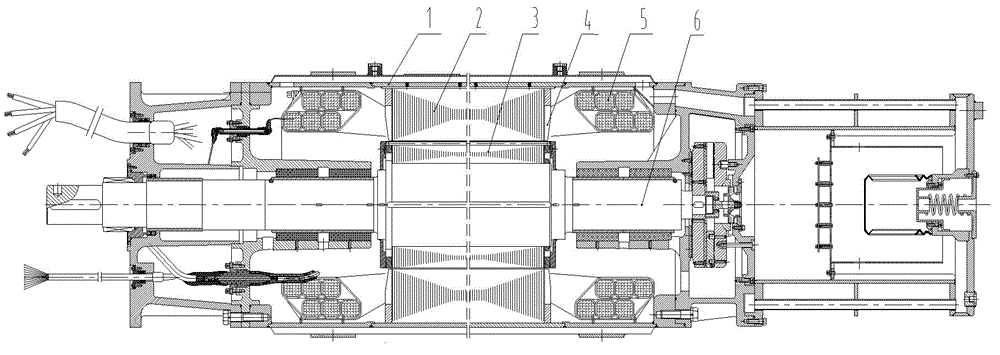

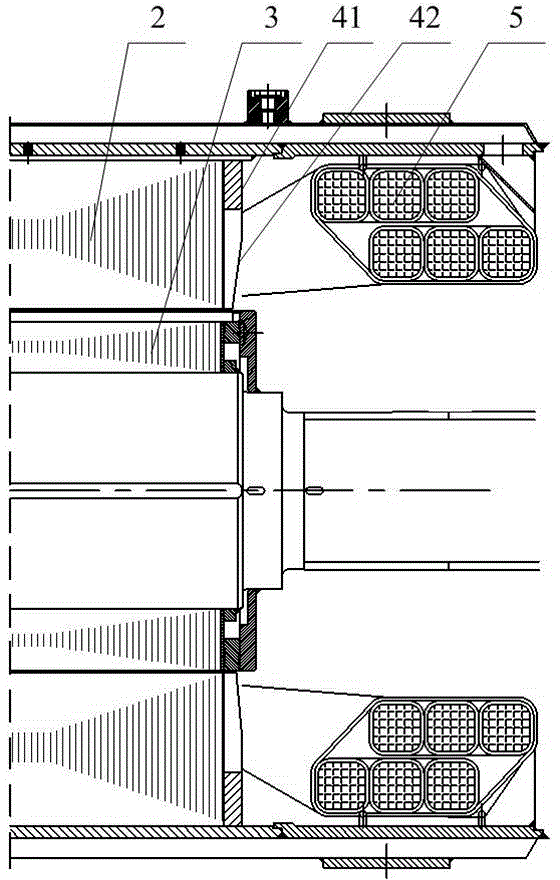

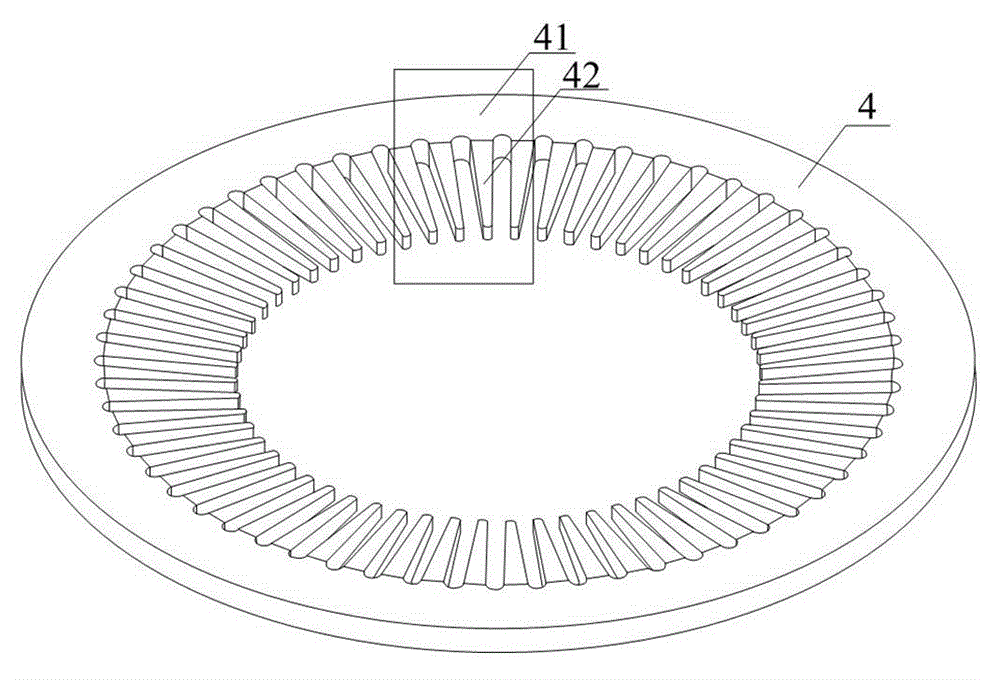

[0021] see figure 1 with figure 2 , the water-filled submersible motor that improves the stator core pressure ring includes a casing 1, a stator 2, a rotor 3 and a rotating shaft 6, the stator 2 is fixed in the casing 1, the rotor 3 is fixed on the rotating shaft 6, and the shaft of the stator core Stator pressure rings 4 are respectively fixedly installed at both ends; end windings 5 are respectively provided in the housings outside the four stator pressure rings at both ends. see image 3 with Figure 4 , the outer circumference of the stator pressure ring is the yoke 41, the inner circumferen...

Embodiment 2

[0024] Taking the motor YBQ2800 / 4-S (10000) water-filled submersible motor for mining increased safety submersible pumps as an example, the relevant parameters of the water-filled submersible motor are as follows: the outer diameter of the stator core is 850mm, the inner diameter of the stator core is 462mm, the stator core length is 1550mm, and the number of stator slots is 60;

[0025] The thickness a of the stator pressure ring is 25mm, the groove type of the stator pressure ring 4 is parallel grooves, the number of teeth of the tooth part 42 is 60, and is evenly distributed along the circumferential direction; the groove depth h of the tooth groove is 135.2mm, and the groove width 2R is 15.4 mm, and the groove bottom is a semicircle with a radius R of 7.7mm; the side of the teeth of the stator pressure ring adjacent to the end winding 5 is a slope inclined to the center of the circle, and the slope angle α of the slope is 6°.

[0026] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com