Antireflection structure, transfer mold, production methods therefor, and display device

A manufacturing method and anti-reflection technology, which are used in semiconductor/solid-state device manufacturing, identification devices, lighting devices, etc., can solve problems such as difficult to see images, and achieve the effects of good decorative effect, enhanced color tone, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

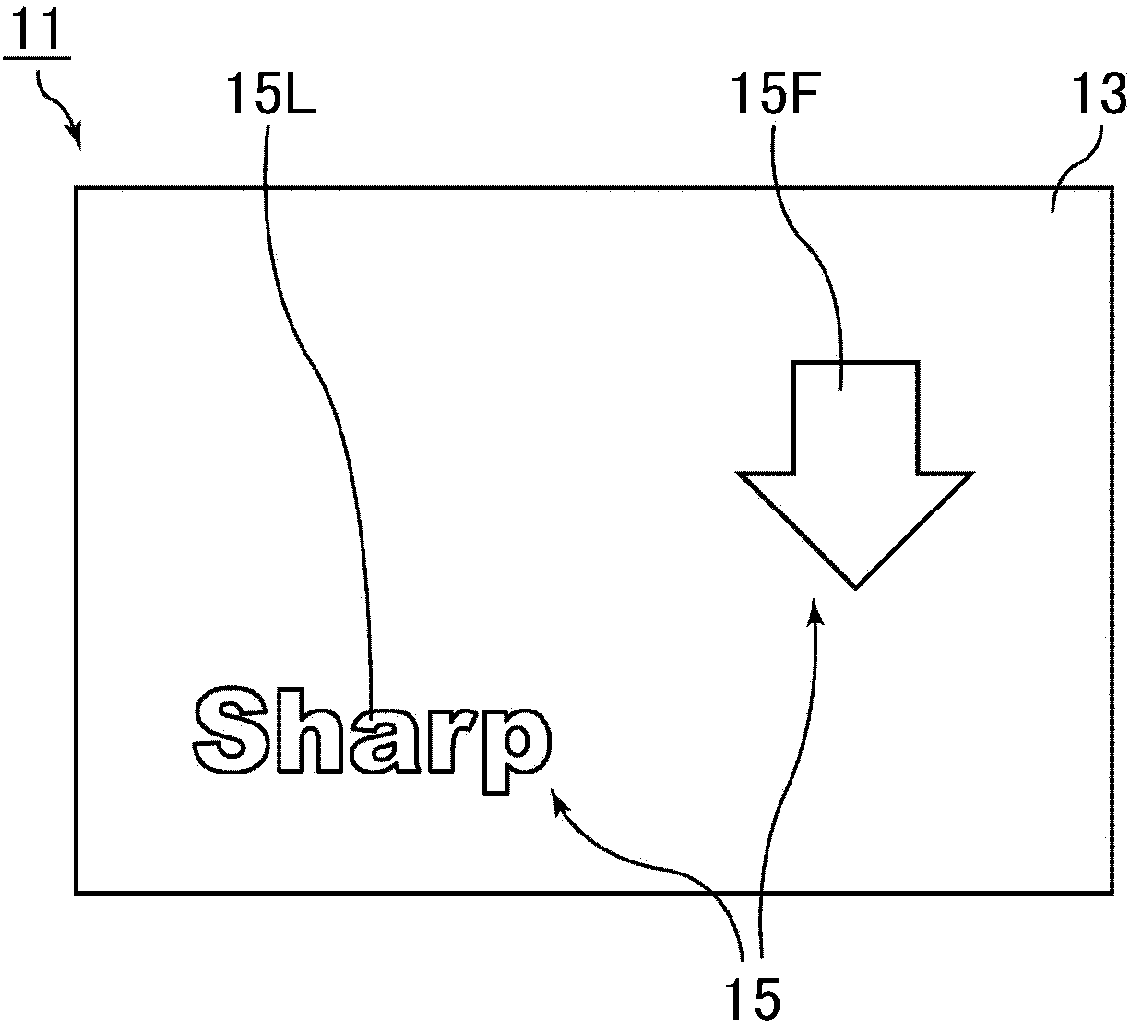

[0104] figure 1 It is a schematic plan view of the antireflection film of Embodiment 1. The antireflection film 11 of Embodiment 1 has: the first region 13, which has a concave-convex structure (first moth-eye structure) including a transparent resin whose period (width between adjacent vertices) is smaller than the wavelength of visible light on the surface; The region (region with different properties) 15 has a concave-convex structure made of a transparent resin whose period (width between adjacent vertices) is smaller than the wavelength of visible light, which is different from the concave-convex structure of the first region. The first region 13 and the second region 15 having a moth-eye structure are regions in which a concavo-convex structure for reducing reflection on the surface of the antireflection film 11 is formed. The antireflection film 11 of Embodiment 1 corresponds to a moth-eye sheet.

[0105] In Embodiment 1, such as figure 1 As shown, portions having ...

Embodiment approach 2

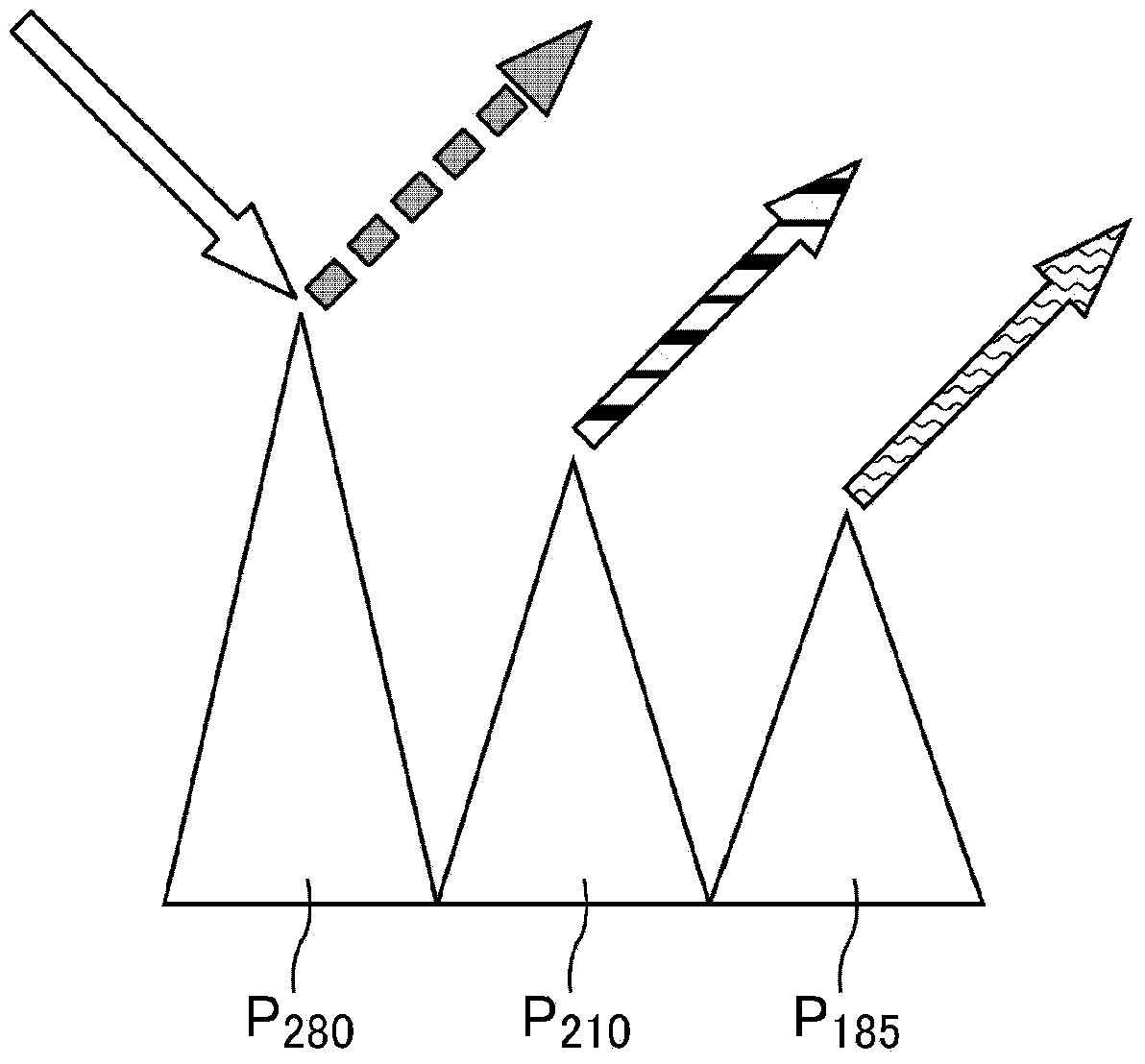

[0170] Figure 17 It is a schematic diagram of the mold for transfer of Embodiment 2. Hereinafter, a method of manufacturing a moth-eye surface having a part of which has different reflection characteristics will be described in detail.

[0171] The moth-eye is formed by continuous transfer using a transfer mold 321 such as a roll type having a concave mold pattern formed on its surface. Here, as an example, a method of producing an antireflection film using a roll-type transfer mold 321 will be described.

[0172] The roll-type transfer mold 321 is, for example, a roll-type mold made by cutting aluminum (Al) or a mold formed by forming an aluminum film on the surface of a thin sleeve as a base material. These aluminum surfaces are repeatedly anodized and etched. That is, aluminum oxide (Al oxide) in which many tiny pores (pores) below the wavelength of visible light are formed over a wide range of the surface of the mold for transfer by anodizing aluminum is produced. 2 o...

other Embodiment approach

[0234] In the above-mentioned embodiment, the surface shape of the transfer mold, the antireflection film, and the surface shape of the display device are substantially flat except for unevenness due to the moth-eye structure, but they may be preliminarily anodized before anodizing. Sandblasting or the like is used to provide a scattering concave-convex structure.

[0235] In each of the above-described embodiments, resins such as photocurable resins and thermosetting resins that cure under certain conditions can be used as the main component of the antireflection film from the viewpoint of precisely forming a moth-eye structure. Here, a material (transparent particles, etc.) having a refractive index different from that of the resin material that is the main component of the antireflection film may be partially dispersed in the base layer (inside) of the antireflection film.

[0236] In addition, although oxalic acid is used in the anodizing treatment step shown in Embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com