Wheel barrow high-pressure static sprayer

A high-voltage electrostatic spraying and cart-type technology, which is applied in the fields of trapping or killing insects, applications, animal husbandry, etc., can solve the problems of polluted environment, unsatisfactory liquid atomization effect and adsorption capacity, low pesticide usage rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

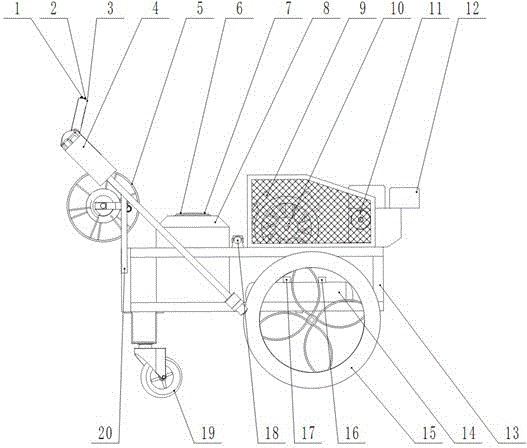

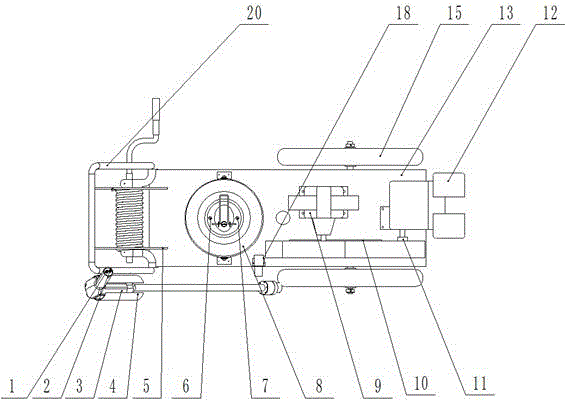

[0015] Such as figure 1 As shown, the front wheel 15 and the universal rear wheel 20 are arranged at the lower end of the vehicle frame 13, the internal combustion engine 12 is arranged at the front end of the vehicle frame 13, and the air compressor head 9 is arranged at the middle part of the vehicle frame 13, and is installed on the vehicle frame by metal hoses and devices. The air intake port of the air storage tank 14 of the front end in 13 is connected, and is connected by the small pulley 11 on the belt and internal combustion engine 12 axles by the big pulley 10.

[0016] Such as figure 1 As shown, the winder 5 and the double parallel pipe wound on the pipe winder 5 are arranged on the upper part of the rear end of the frame 13, and the large-diameter end of the head end of the double parallel pipe is connected to the pneumatic high-voltage electrostatic spray gun 3 through a quick-plug connector. The air inlet port 1 at the tail end of the gun handle is connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com