Caramel essence used in coffee and preparation method thereof

A technology of caramel essence and essence, which is applied in the field of coffee caramel essence and its preparation, which can solve the problems that the aroma and aroma characteristics of caramel essence are not obvious enough, the aroma of caramel essence is not realistic and natural, and the fragrance retention time is short. Natural aroma effect, soft and natural aroma, strong aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

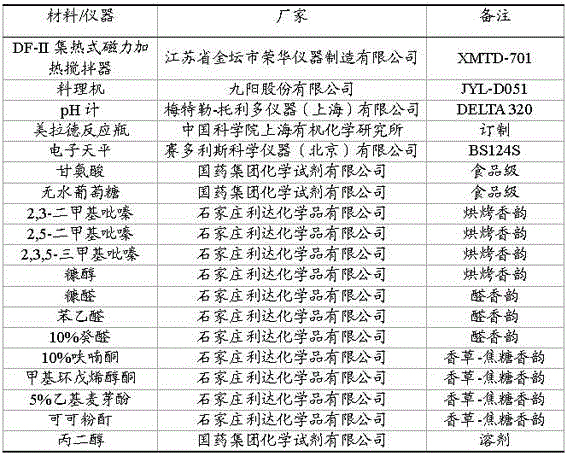

Method used

Image

Examples

Embodiment 1

[0037] A caramel flavor for coffee, which is composed of a heat-reactive caramel flavor and a blended caramel flavor, and the quality of the blended flavor is 0.5% of the quality of the heat-reactive flavor;

[0038] The thermal reaction caramel flavor is calculated by weight percentage, and its raw material composition and content are as follows:

[0039] Glycine 3.33%

[0040] Anhydrous dextrose 7.98%

[0041] 1,2-Propanediol 62.08%

[0042] The balance is distilled water;

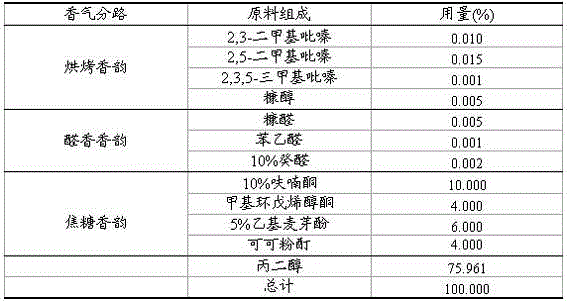

[0043] The blended caramel flavor is calculated by weight percentage, and its raw material composition and content are as follows:

[0044]

[0045] The above-mentioned preparation method of caramel flavor for coffee specifically includes the following steps:

[0046] (1) Preparation of thermal reaction caramel flavor

[0047] Add 3.33g of glycine, 7.98g of anhydrous glucose, 62.08g of 1,2-propanediol and 26.61g of distilled water into the Maillard reaction flask, then adjust the pH to 6.0 with a 5.0% aqueous NaOH sol...

Embodiment 2

[0055] A caramel flavor for coffee, which is composed of a heat-reactive caramel flavor and a blended caramel flavor, and the quality of the blended flavor is 0.8% of the quality of the heat-reactive flavor;

[0056] The thermal reaction caramel flavor is calculated by weight percentage, and its raw material composition and content are as follows:

[0057] Glycine 3. 33%

[0058] Anhydrous dextrose 7.98%

[0059] 1,2-Propanediol 57.65%

[0060] The balance is distilled water;

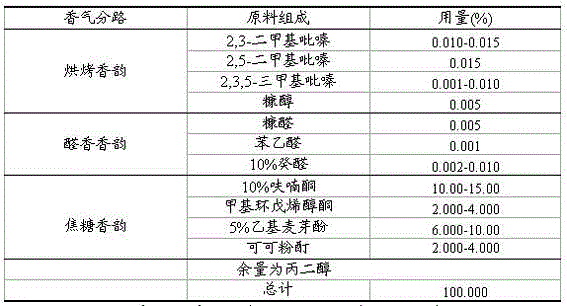

[0061] The blended caramel flavor is calculated by weight percentage, and its raw material composition and content are as follows:

[0062]

[0063] The above-mentioned preparation method of caramel flavor for coffee specifically includes the following steps:

[0064] (1) Preparation of thermal reaction caramel flavor

[0065] Add 3.33g of glycine, 7.98g of anhydrous glucose, 57.65g of 1,2-propanediol and 31.04g of distilled water into the Maillard reaction flask, then adjust the pH to 6.0 with a 5.0% NaOH aqueous so...

Embodiment 1

[0083] Coffee powder without caramel flavor for coffee obtained in Example 1, calculated in parts by weight, and its raw material composition and content are as follows:

[0084] Original coffee powder 1.20 servings

[0085] Nano silica 1.00 part

[0086] The above-mentioned coffee powder containing caramel flavor for coffee, the specific steps of the preparation method are as follows:

[0087] 18.6 g of original coffee powder and 15.5 g of nano-silica were thoroughly mixed with a Joyoung cooking machine to obtain coffee powder without the caramel flavor for coffee obtained in Example 1.

[0088] The brewing method of the coffee powder without caramel flavor for coffee obtained in Example 1 is as follows:

[0089] Add boiling water to the coffee powder without caramel flavor for coffee obtained in Example 1, and stir evenly. The amount of boiling water added is the same as the coffee powder without caramel flavor for coffee obtained in Example 1: Boiling water is 4.8 g: The ratio of 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com