Method for producing pomegranate juice

A technology of pomegranate juice and pomegranate seeds, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of sensory quality decline, inability to directly face end consumers, loss of nutrients, etc., so as to overcome the quality decline and have a good application prospect. and promotion of value, preservation of sensory and nutritional quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] After the raw materials are cleaned and impurity removed, the pomegranates are sorted to remove rotten fruits. The sorted pomegranates are peeled and seeded. The capsuled pomegranate seeds are then placed in a juicer for juice extraction. The obtained crude pomegranate juice is subjected to continuous centrifugation at a speed of 3000 rpm / min. Then the pomegranate juice obtained after centrifugation is subjected to ultrafiltration. The ultrafiltration pressure is 3bar and the temperature is 30°C. It is a continuous treatment. The obtained clarified juice is concentrated by reverse osmosis. After being 18Brix, the obtained concentrated juice was treated at 500 MPa, 10-30° C. for 5 minutes with ultra-high pressure to obtain the pomegranate juice provided by the present invention.

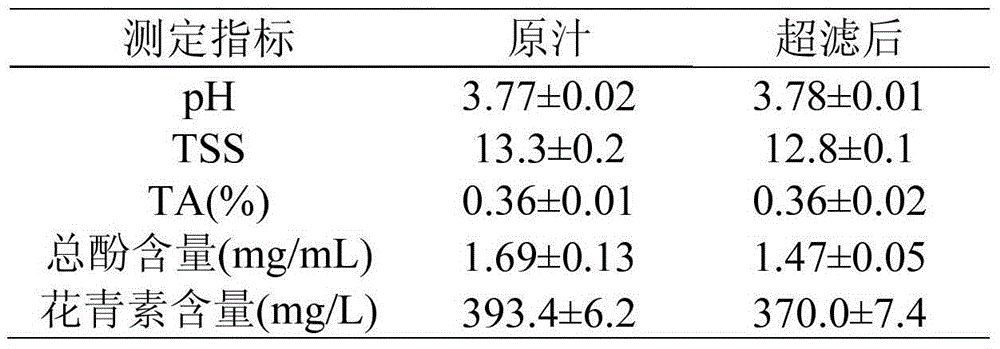

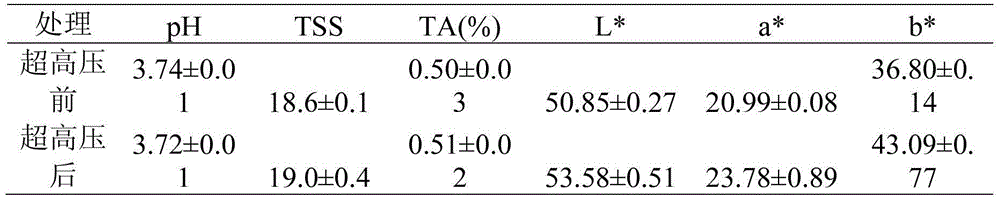

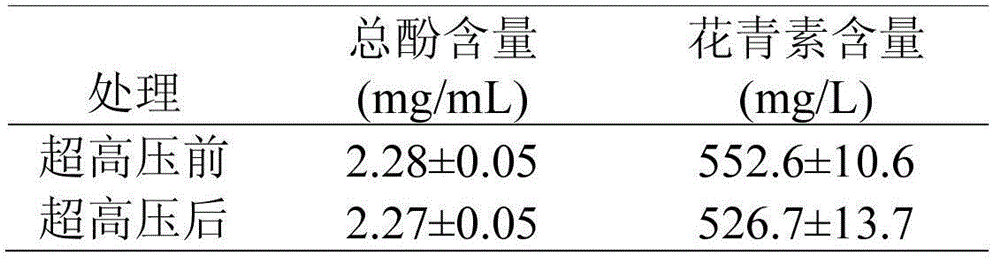

[0018] Detection of pomegranate juice quality before and after ultrafiltration, reverse osmosis and ultra-high pressure:

[0019] 1) Detect the quality of the crude pomegranate juice before ...

Embodiment 2

[0031] After the raw materials are cleaned and impurity removed, the pomegranates are sorted to remove rotten fruits. The sorted pomegranates are peeled and seeded. The capsuled pomegranate seeds are then placed in a juicer for juice extraction. The obtained crude pomegranate juice is subjected to continuous centrifugation at a speed of 2000 rpm / min. Then the pomegranate juice obtained after centrifugation is subjected to ultrafiltration. The ultrafiltration pressure is 2bar and the temperature is 25°C. After being 15Brix, the obtained concentrated juice was treated at 300 MPa, 10-30° C. for 2 minutes with ultra-high pressure to obtain the pomegranate juice provided by the present invention.

[0032] The pH value, soluble solids content, total acid content, L* value, a* value, b* value, total phenol and anthocyanin content of pomegranate juice obtained in this example have no substantial difference from Example 1.

Embodiment 3

[0034] After the raw materials are cleaned and impurity removed, the pomegranates are sorted to remove rotten fruits. The sorted pomegranates are peeled and seeded. The capsuled pomegranate seeds are then placed in a juicer for juice extraction. The obtained crude pomegranate juice is subjected to continuous centrifugation at a speed of 2500 rpm / min. Then the pomegranate juice obtained after centrifugation is subjected to ultrafiltration, the ultrafiltration pressure is 2.5bar, and the temperature is 25°C. It is a continuous treatment. The obtained clarified juice is concentrated by reverse osmosis. After the sugar content reaches 16Brix, the obtained concentrated juice is treated at 350MPa and 10-30°C for 3 minutes with ultra-high pressure to obtain the pomegranate juice provided by the invention.

[0035] The pH value, soluble solids content, total acid content, L* value, a* value, b* value, total phenol and anthocyanin content of pomegranate juice obtained in this example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com