High-efficiency edge brushing and dust collection device for mesh belt or steel belt

A dust suction device and steel belt technology, applied in the direction of dust removal, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of leftover materials flying randomly, the edge of the nanofiber film is damaged and irregular, and the quality of the product is increased. Ensure non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

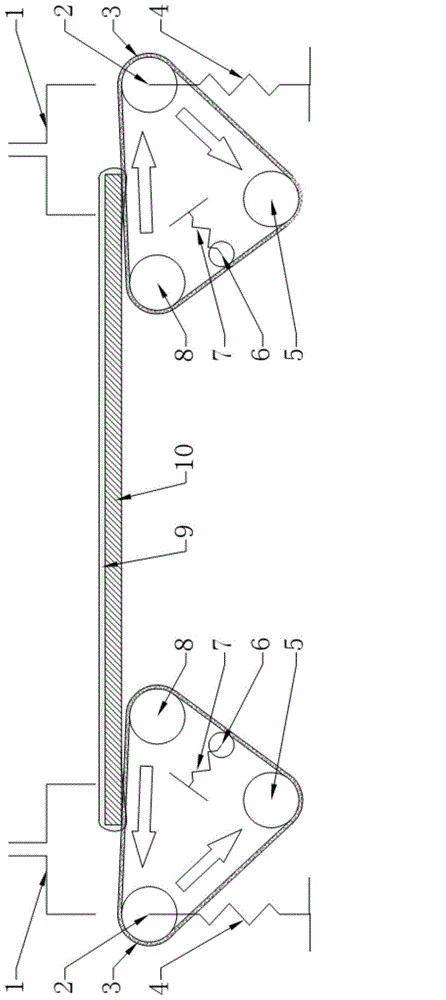

[0017] Such as figure 1 As shown, a brush edge dust suction device of a mesh belt or a steel belt of the present invention comprises: a driving wheel 5, a driven wheel 8, a positioning wheel 2, a belt wire brush 3 and a dust collection cover 1;

[0018] Described driving wheel 5 is driven by motor; Described driving wheel 5, driven wheel 8, positioning wheel 2 are synchronously driven by belt wire brush 3, and described driving wheel 5, driven wheel 8, positioning wheel 2 are synchronous belts wheel;

[0019] The driving wheel 5 is located below, the positioning wheel 2 and the driven wheel 8 are located above and the positioning wheel 2 forms a triangular structure on the outside.

[0020] The positioning wheel 2 is provided with a height positioning regulator 4 .

[0021] A belt tensioner 6 is provided between the driving pulley 5 and the driven pulley 8 .

[0022] The device is symmetrically arranged on the left and right sides of the mesh belt or steel belt with the mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com