Hand-operated tea tray engraving plane milling apparatus

A technology of plane milling and tea tray, which is applied in the field of manual tea tray engraving plane milling device, and can solve problems such as affecting the quality of tea sets.

Inactive Publication Date: 2015-03-11

卢爱勤

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the production of tea trays, root carving tea sets, etc., when it is necessary to cut and dig out the surface of the disk, the practice is to mark each plane range on the wood to be cut, and then manually hold the electric tool according to the mark. For cutting, skilled craftsmen can complete this work relatively quickly and accurately, but this requires high skills, otherwise it will directly affect the quality of the tea set

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0007] Shown in the accompanying drawings is exactly the embodiment of the present invention, except that it is applied to the rough processing operation of the personalized tea tray, it can also be widely used in the surface milling and grinding processing operations of other wood and stone materials.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

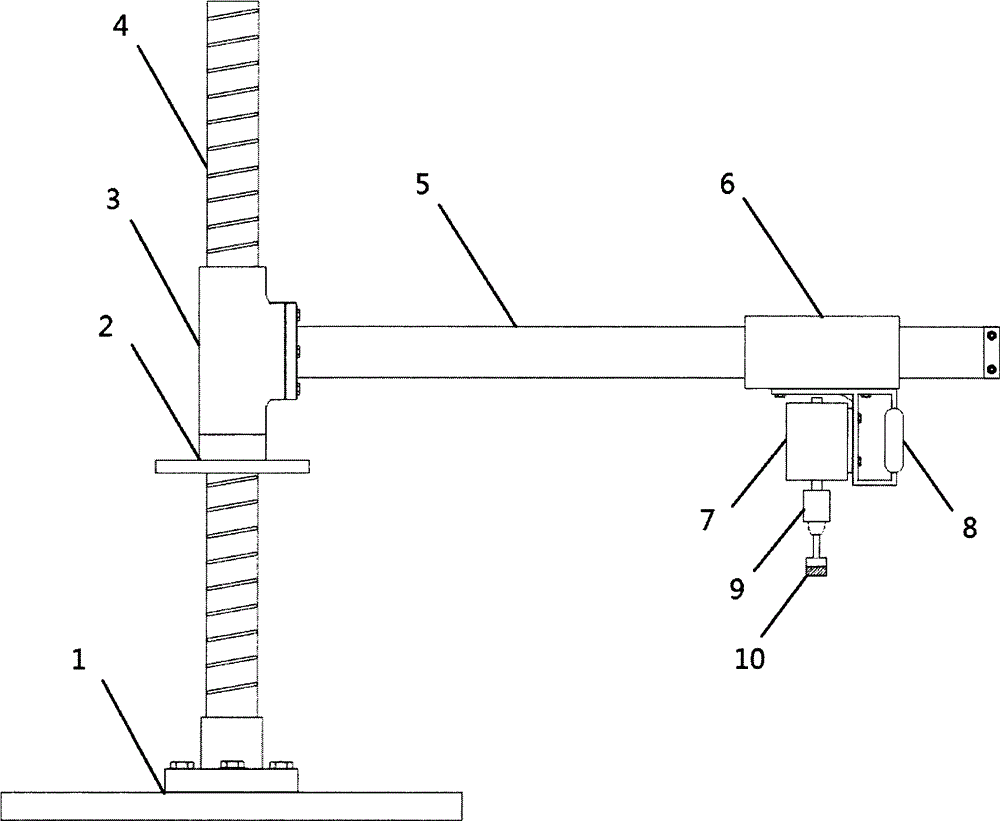

The invention provides a hand-operated tea tray engraving plane milling apparatus which is mainly composed of a pedestal (1), a lifting nut (2), a sleeve (3), a vertical column (4), a slide rail (5), a slide block (6), an engraving motor (7), a handle (8), a drill chuck (9) and a milling cutter (10). The milling apparatus is characterized in that one end of the vertical column (4) is fixed to the pedestal (1); the sleeve (3) sleeves the vertical column (4); the sleeve can rotate 360 degrees around the vertical column (4); the sleeve can move up and down on the vertical column (4) by adjusting the lifting nut (2); the slide rail (5) is connected to the sleeve (3); the slide block (6) is attached to the slide rail (5) and can perform horizontal reciprocating motion; the engraving motor (7) and the handle (8) are installed on the slide block (6); and the drill chuck (9) is axially arranged on the motor so as to fix the milling cutter (10). The apparatus has advantages of simple structure, convenient operation, easy maintenance, three-dimensional operation, precise localization and the like, and is suitable for rough machining operations such as cutting, polishing and the like of customized tea tray planes.

Description

technical field [0001] The invention relates to a tea set plane processing method and its device, which is especially suitable for tea sets with many root carvings on the plane. Background technique [0002] In the production of tea trays, root carving tea sets, etc., when it is necessary to cut and dig out the surface of the disk, the practice is to mark each plane range on the wood to be cut, and then manually hold the electric tool according to the mark. For cutting, skilled craftsmen can do this work relatively quickly and accurately, but this requires high skills, otherwise it will directly affect the quality of the tea set. [0003] The object of the present invention is to provide a tea set plane processing method and its device, which can solve the shortcomings of the above-mentioned prior art and meet the requirements of time saving, labor saving and precise processing. Description of drawings [0004] The accompanying drawings of the description are schematic di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B27C5/10

CPCB27C5/10

Inventor 卢爱勤

Owner 卢爱勤

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap