PET bottle flake or thin film drying device

A drying device and bottle flake technology, which is applied in the field of drying devices, can solve the problems of large pipe-side resistance, poor moisture removal effect and high energy consumption of spiral pipes, and achieves lower production cost, lower energy consumption, and good moisture drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

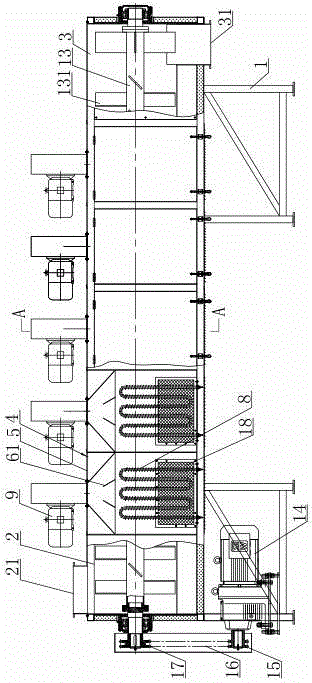

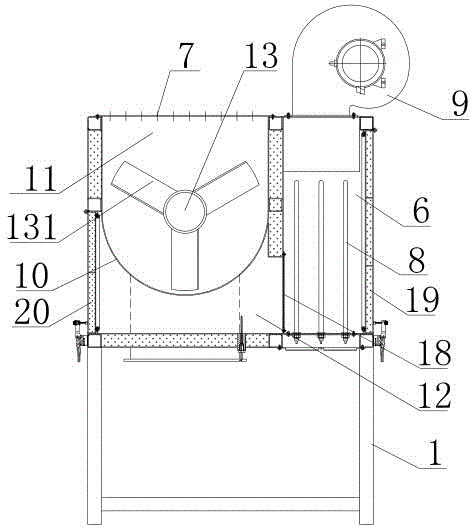

[0014] The present invention will be further described in detail below with reference to the drawings and preferred embodiments.

[0015] Such as figure 1 , figure 2 As shown, the drying device for PET bottle flakes or film includes: a frame 1, where a feeding box 2 and a discharging box 3 are arranged on the frame 1, and a feeding port 21 is arranged on the top of the feeding box 2, and the discharging The bottom of the box 3 is provided with a discharge port 31, and at least two drying box units 4 are provided between the feeding box 2 and the discharging box 3. The number of drying box units 4 can be set according to actual needs. The structure of the dry box unit 4 includes: a housing 5, the inner cavity of the housing 5 is divided into a drying chamber and a heating chamber 6, and the heating chamber 6 is provided with a heater. The heater in this embodiment is an electric heating tube 8. The housing 5 at the top of the heating chamber 6 is provided with a fan 9 which cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com